Innovations in Composite Reflective Insulation Films: Applications and Advancements

2025-06-19

Composite reflective insulation films are advanced materials designed to enhance thermal management across various industries, from construction to automotive engineering. These films combine multiple layers—often including metallic coatings, polymers, and nano-enhanced materials—to improve heat reflection, insulation, and energy efficiency.

Recent advancements have led to specialized films tailored for different applications, such as ultra-thin solutions for buildings, cost-effective HVAC insulation, eco-friendly recyclable films, and high-performance automotive thermal management. This article explores four key developments in composite reflective insulation films, detailing their benefits, working principles, and industry applications.

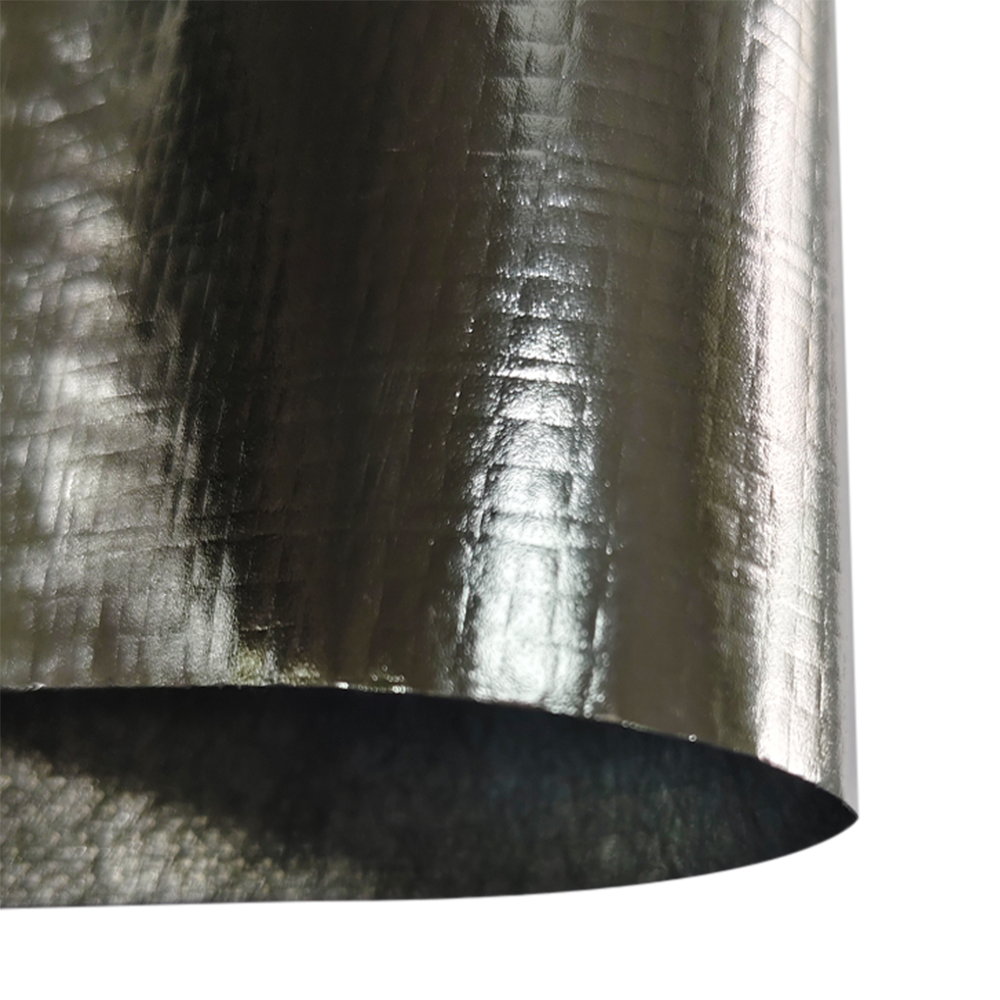

Multilayer Composite Reflective Film AWN140

1. Ultra-Thin Composite Reflective Insulation Film for Energy-Efficient Buildings

With rising energy costs and stricter environmental regulations, the demand for energy-efficient building materials has surged. Ultra-thin composite reflective insulation films offer a lightweight yet highly effective solution for reducing heat transfer in walls, roofs, and windows.

Key Features & Benefits

Thin yet Powerful: Despite being only a few micrometers thick, these films provide high reflectivity (up to 95%) against radiant heat.

Easy Installation: Their flexibility allows seamless integration into existing structures without adding bulk.

Year-Round Efficiency: Helps maintain indoor temperatures, reducing heating costs in winter and cooling costs in summer.

Applications

Residential & Commercial Buildings: Used in smart windows, roofing membranes, and wall insulation.

Green Construction: Supports LEED-certified buildings by improving thermal performance.

Research is focusing on integrating photovoltaic-reactive films, which could simultaneously reflect heat and generate solar energy.

2. Low-Cost Composite Reflective Insulation Film for HVAC Applications

Heating, ventilation, and air conditioning (HVAC) systems consume significant energy, making insulation critical for efficiency. Low-cost composite reflective films provide an economical way to enhance thermal retention in ductwork and piping.

Key Features & Benefits

Cost-Effective Alternative: Reduces reliance on expensive foam-based insulation.

Moisture & Corrosion Resistance: Prevents condensation in ducts, extending HVAC lifespan.

Fire Retardant Properties: Some variants include flame-resistant layers for industrial safety.

Applications

HVAC Duct Wrapping: Minimizes heat loss in air distribution systems.

Industrial Piping Insulation: Used in factories and power plants to maintain fluid temperatures.

Emerging self-adhesive films could simplify installation, further cutting labor costs.

3. Eco-Friendly Composite Reflective Film with Recyclable Materials

Sustainability is a growing priority, leading to the development of eco-friendly reflective films made from biodegradable or recyclable polymers.

Key Features & Benefits

Reduced Carbon Footprint: Uses plant-based or recycled polyester layers.

Non-Toxic Additives: Avoids harmful chemicals like PFAS.

End-of-Life Recyclability: Can be reprocessed without degrading performance.

Applications

Residential Insulation: Ideal for eco-conscious homeowners.

Temporary Structures: Used in disaster relief shelters due to low environmental impact.

Research is exploring algae-based films, which could offer fully biodegradable insulation solutions.

4. High-Performance Composite Reflective Film for Automotive Thermal Management

Modern vehicles, especially electric cars, require efficient thermal management to protect batteries and improve cabin comfort. High-performance reflective films help regulate temperatures in critical components.

Key Features & Benefits

Heat Shielding for Batteries: Prevents overheating in EV battery packs.

UV & Infrared Reflection: Keeps interiors cooler, reducing AC load.

Lightweight & Durable: Withstands vibrations and extreme temperatures.

Applications

Electric Vehicle Battery Packs: Enhances thermal runaway prevention.

Automotive Interiors: Applied to dashboards and sunroofs to reduce heat absorption.

Self-healing films that repair minor scratches could improve longevity in harsh conditions.

日本語

日本語 Русский

Русский España

España عرب .

عرب .