Liquid-applied vs. Self-adhered: Which Air and Water Barrier Membrane Application Method Reduces Onsite Labor Costs and Installation Errors?

2026-02-04

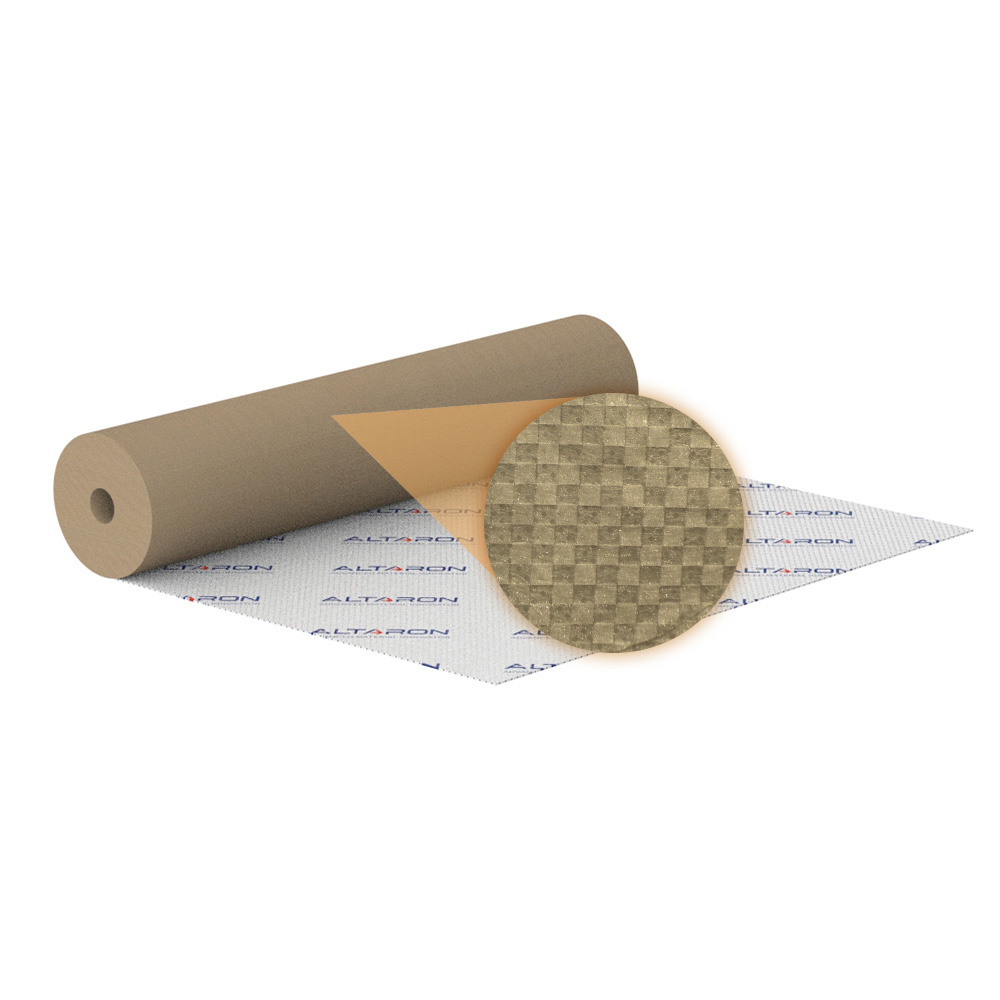

In the high-stakes world of building envelope engineering, the selection of an air and water barrier membrane is a critical decision that impacts a structure's long-term hydrothermal performance. As building codes become increasingly stringent regarding energy efficiency and moisture management, B2B procurement professionals must weigh the benefits of application methods. Jiangsu Aotelong New Materials Co., Ltd. (Zhongning New Materials Jiangsu Co., Ltd.), based in the new materials industrial hub of Yangzhou, specializes in high-performance building enclosure solutions. With factory inspections passed by the US ICC-ES and the UK BBA, our R&D focus ensures that whether you utilize a self-adhered vapor permeable air barrier or a liquid solution, the material integrity remains uncompromised.

The Mechanical Distinction: Liquid-Applied vs. Sheet-Based Systems

Liquid-applied membranes are typically sprayed or roller-applied directly onto the substrate, creating a monolithic, seamless layer that excels in complex geometries. In contrast, self-adhered sheets are factory-controlled in thickness and offer immediate protection but require meticulous overlapping and detailing. While liquid systems eliminate the risk of seam failure, they are highly dependent on ambient weather conditions and applicator skill. Conversely, a commercial grade weather barrier for multi-family housing in sheet form provides consistent mil-thickness across the entire surface, regardless of the applicator's technique.

| Feature | Liquid-Applied Membrane | Self-Adhered Sheet Membrane |

| Installation Continuity | Seamless, monolithic coating. | Lapped seams; requires detailing tape. |

| Thickness Control | Variable (Dependent on applicator). | Factory-set (Consistent mil-thickness). |

| Weather Sensitivity | High (Cannot apply in rain/extreme cold). | Lower (Wider installation window). |

Reducing Labor Costs: Speed vs. Precision

Labor constitutes a significant portion of the building envelope budget. Liquid-applied systems can be faster for large, flat expanses where spray rigs can cover thousands of square feet daily. However, for a permeable air barrier for wood frame construction, self-adhered membranes often reduce labor costs by eliminating the need for specialized spray equipment and the extensive masking required to prevent overspray. Furthermore, the "instant grab" of high-tack sheet membranes allows for immediate subsequent trade work, whereas liquid systems require specific cure times before cladding or insulation can be installed.

| Labor Factor | Liquid Systems | Self-Adhered Systems |

| Setup Time | Extensive (Equipment prep and masking). | Minimal (Unroll and apply). |

| Cure Time | 12-24 hours (Weather dependent). | Zero (Immediate cladding possible). |

| Skill Level Required | Specialized rig operators needed. | General labor with basic training. |

Minimizing Installation Errors: The Risk of Human Factor

Installation errors are the leading cause of building envelope failure. For liquid membranes, the primary error is "under-application," where the membrane is applied too thin to resist air pressure or water ingress. With a self-adhered vapor permeable air barrier, the primary risk is "reverse-lapping" or poor adhesion at the seams. To mitigate these risks, Jiangsu Aotelong's high-permeability waterproof breathable membrane products are designed for high-tack reliability. Engineers often prefer sheet membranes for exterior wall moisture management for commercial buildings because they are easier to inspect visually—if the lap is correct, the system is likely integral.

| Error Source | Liquid System Risks | Self-Adhered System Risks |

| Substrate Condition | Moisture/Dust prevents chemical bond. | Primers may be needed for some surfaces. |

| Visual Inspection | Difficult to verify mil-thickness. | Easy to verify overlap and seal. |

| Seal Integrity | Excellent around penetrations. | Requires accessory tapes for penetrations. |

Aotelong's Engineering Advantage: Certified Performance

Jiangsu Aotelong New Materials Co., Ltd. produces a diverse range of enclosure materials that have passed the National Building Materials Testing Center and European CE certification. Our UV resistant air barrier for open joint cladding and vapor barrier membranes are engineered to withstand the rigors of modern construction sites. By integrating R&D with large-scale production, we ensure that every roll of our air and water barrier membrane meets the technical requirements of the UK BBA and US ICC-ES inspections, providing a robust defense against air leakage and liquid water while allowing necessary water vapor to escape.

- High Permeability: Facilitates the drying of wall assemblies to prevent mold.

- Structural Integrity: High tensile strength prevents tearing during high-wind events.

- Versatility: Suitable for medical, agricultural, and commercial building enclosures.

Conclusion: Choosing the Optimal System

For projects with complex detailing and numerous penetrations, liquid-applied systems may reduce the risk of air leakage. However, for most commercial and residential builds, a self-adhered vapor permeable air barrier offers superior thickness control, lower equipment-related labor costs, and a more straightforward inspection process. By selecting a certified air and water barrier membrane from Jiangsu Aotelong, developers can ensure their building envelope is both cost-effective and engineered for high-performance longevity.

Technical Standard: Verifying the Continuous Envelope

The primary goal of the air and water barrier membrane is continuity. Any gap, even a few millimeters wide at a window transition or a pipe penetration, can lead to significant energy loss and interstitial condensation. At Aotelong, our R&D focus on self-adhered vapor permeable air barriers ensures high-tack performance, but onsite verification is the final safeguard against installation errors.

1. Substrate Preparation and Environmental Conditions

Before any membrane application, the substrate must be mechanically sound and chemically compatible with the adhesive or liquid coating. For permeable air barriers for wood frame construction, moisture content in the sheathing is a critical variable that can lead to adhesive failure if not monitored.

| Inspection Point | Acceptance Criteria | Verification Method |

| Substrate Moisture | < 19% for wood; < 4% for concrete. | Electronic Moisture Meter. |

| Surface Cleanliness | Free of dust, oils, and laitance. | "White Glove" or Tape Pull Test. |

| Ambient Temperature | Within manufacturer's specified range. | Infrared Thermometer. |

2. Application Thickness and Lap Integrity

For liquid systems, the wet-film thickness (WFT) must be consistent to achieve the required dry-film thickness (DFT). For sheet systems, like our commercial grade weather barrier for multi-family housing, the focus shifts to the "shingle-lap" orientation and the pressure applied during the roll-out phase.

- WFT Verification: For liquid-applied membranes, perform gauge tests every 100 square feet to ensure no "thin spots" exist.

- Lap Width: Verify a minimum of 2 to 4 inches (50-100mm) of overlap on all horizontal and vertical seams.

- Rolling: All self-adhered sheets must be "J-rolled" with firm pressure to activate the pressure-sensitive adhesive and eliminate "fish-mouth" air pockets.

3. Penetration Detailing and Transitions

The majority of leaks occur at penetrations. Whether you are using a UV resistant air barrier for open joint cladding or a standard membrane, detailing at windows, ducts, and structural steel requires secondary flashing or high-movement sealants.

| Detail Area | Critical Verification | Common Failure Mode |

| Window/Door Ruffs | Correct shingle-lapping of flashing. | Reverse-lapping (Water enters wall). |

| Pipe Penetrations | Flexible gasket or liquid-flashing boot. | Cracking due to thermal expansion. |

| Expansion Joints | Loop in membrane to allow movement. | Tearing of the membrane over the gap. |

4. Adhesion and Continuity Testing

Once the air and water barrier membrane installation is complete, a qualitative or quantitative test should be performed. Jiangsu Aotelong recommends the ASTM D4541 pull-adhesion test for critical commercial builds to ensure the membrane will not delaminate under high-wind suction loads.

- Visual Audit: 100% inspection of all seams for full contact.

- Adhesion Testing: Conduct "mock-up" pull tests to verify the bond to the specific site substrate.

- Whole-Building Testing: Consider a blower-door test to verify the overall air-leakage rate ($cfm/ft^2$) against the design specification.

Aotelong: Your Partner in Building Science

By following this QC checklist and utilizing Aotelong's CE and BBA certified membranes, your project can achieve a high-performance envelope that stands the test of time. Our Yangzhou-based manufacturing facility remains at your service for technical consultations and the supply of world-class building enclosure materials.

Frequently Asked Questions (FAQ)

- Q1: Is a primer always necessary for self-adhered membranes?

A: It depends on the substrate and temperature. While many modern "high-tack" membranes are primerless on plywood or OSB, concrete and CMU often require a primer to ensure a durable bond. - Q2: How does the "mil-thickness" affect the performance of an air barrier?

A: Mil-thickness determines the membrane's ability to resist water head pressure and air permeance. Sheet membranes provide a factory-guaranteed thickness, whereas liquid systems require wet-film-gauge testing during application. - Q3: Can these membranes be used in open-joint rainscreen systems?

A: Yes, but you must specify a UV resistant air barrier for open joint cladding, as standard membranes will degrade when exposed to the sun's rays through the gaps in the cladding. - Q4: What is the difference between vapor permeable and vapor barrier?

A: A permeable membrane allows water vapor to pass through (drying out the wall), while a vapor barrier (like a vapor barrier membrane) blocks it. Most modern air barriers are designed to be permeable to prevent internal rot. - Q5: Does Jiangsu Aotelong provide international shipping and certification?

A: Yes. We are CE, BBA, and ICC-ES certified, exporting our new material solutions from our large-scale production base in Jiangsu to global markets.

Industry References

- Air Barrier Association of America (ABAA): Standard for liquid-applied and sheet-based air barriers.

- ASTM E2178: Standard Test Method for Air Permeance of Building Materials.

- International Code Council (ICC-ES): Acceptance Criteria for Water-Resistive Barriers (AC38).

- British Board of Agrément (BBA): Technical assessments for building envelope thermal and moisture performance.

日本語

日本語 Русский

Русский España

España عرب .

عرب .