Can Air Permeable Breather Membranes Eliminate the Need for Additional Ridge Ventilation in Cold Pitched Roofs?

2026-02-07

In modern building enclosure design, managing interstitial condensation within cold pitched roofs is a primary concern for structural longevity. The introduction of air permeable breather membranes has revolutionized attic ventilation strategies. Engineers and architects often debate whether the high vapor transmission and air movement allowed by these advanced materials can replace traditional mechanical ventilation methods. Jiangsu Aotelong New Materials Co., Ltd. (Zhongning New Materials Jiangsu Co., Ltd.), a leading enterprise that has passed US ICC-ES and UK BBA factory inspections, specializes in the R&D of high-permeability waterproof breathable membrane solutions. Our products are engineered to meet CE and BBA certifications, providing a robust defense against moisture while optimizing thermal efficiency.

1. The Mechanics of Air Permeability vs. Vapor Permeability

Understanding the distinction between "vapor permeable" and "air permeable" is essential for roofing engineers. Standard membranes are often only vapor permeable (Type LR), meaning they allow molecular water vapor to pass but block liquid water and air. In contrast, air permeable breather membranes allow for a physical flow of air through the fabric, driven by pressure differentials. This dual-action significantly enhances breathable roof membrane condensation control, especially in "non-ventilated" cold roof systems where traditional eaves-to-ridge airflow may be obstructed by insulation.

While standard vapor-permeable membranes rely solely on diffusion to move moisture, air-permeable variants utilize both diffusion and convection, resulting in a much higher rate of moisture removal from the roof void.

| Technical Feature | Air Permeable Breather Membranes | Standard Vapor Permeable (Non-Air Permeable) |

| Moisture Transfer Mode | Diffusion + Convection | Diffusion Only |

| Air Flow Rate | Typically > 20 m3/m2/h at 50Pa | Near Zero (Air-tight) |

| Risk of Condensation | Lowest (Excellent for cold roofs) | Moderate (Requires ventilation gaps) |

2. Eliminating Ridge Ventilation: Regulatory and Engineering Perspectives

A frequent technical question arises: is ridge ventilation necessary with air permeable membrane? According to British BBA certifications and various European building codes, certain air permeable breather membranes are classified as "non-ventilated" roofing underlays. This means that under specific conditions—such as a well-sealed ceiling and the use of a high-permeability waterproof breathable membrane—the requirement for 5mm continuous ridge ventilation may be waived. This simplification reduces labor costs and eliminates potential entry points for wind-driven rain at the ridge line.

Compared to traditional vented systems that require complex ridge tiles and soffit vents, a non-ventilated system using air-permeable tech offers a more streamlined aesthetic and improved airtightness for the overall building envelope.

| System Component | Non-Ventilated (Air Permeable) | Traditional Ventilated System |

| Ridge Tiles | Standard (Mortared or dry) | Specialized Vented Ridge Tiles |

| Eaves Ventilation | Often reduced or eliminated | Mandatory 10mm/25mm continuous vents |

| Installation Complexity | Low (Simpler detailing) | High (Requires multiple components) |

3. Performance in Cold Climates and High-Moisture Environments

The efficacy of air permeable breather membranes is most evident in extreme thermal gradients. In a cold pitched roof, the temperature difference between the attic and the exterior creates a "dew point" on the underside of the underlay. One must ask: how to install air permeable membrane for cold roofs? Proper installation requires the membrane to be draped over rafters with a slight "cove" to allow water runoff, while the high-permeability waterproof breathable membrane works to equalize pressure. Jiangsu Aotelong New Materials produces membranes that maintain breathable membrane UV resistance during the construction phase, ensuring that the material's pore structure does not degrade before the primary roofing is installed.

- Vapor Barrier Synergy: In many designs, combining a breathable underlay with a vapor barrier membrane on the warm side of the insulation further minimizes the moisture load.

- Wind Uplift: Air-permeable materials help balance the pressure between the batten space and the roof void, reducing the wind load on the tiles.

- Reflective Insulation: For enhanced thermal performance, some systems integrate a reflective insulation membrane to reduce radiant heat transfer.

4. Durability and Certification: Ensuring Zero-Defect Enclosures

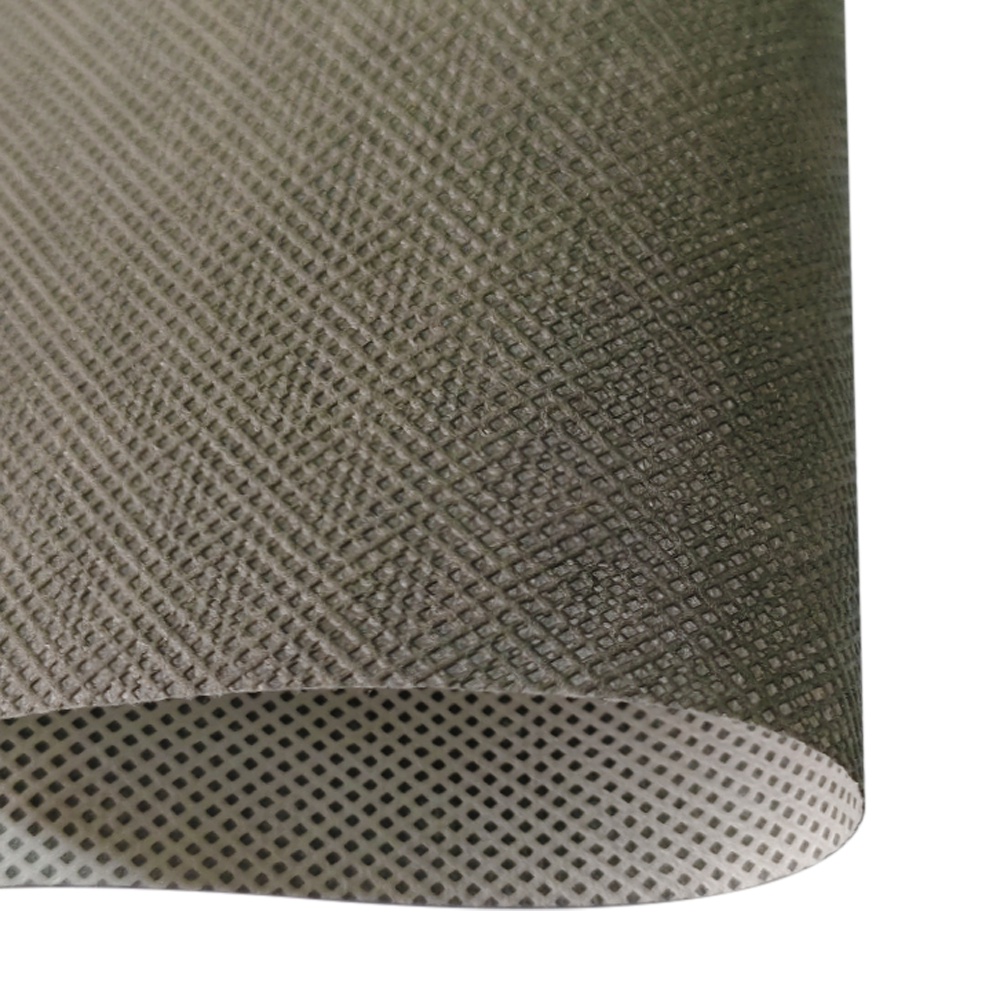

For a building enclosure to be truly high-performance, the materials must be verified by third-party testing. Jiangsu Aotelong has passed the National Building Materials Testing Center's rigorous protocols. We ensure that our high-permeability waterproof breathable membrane maintains its hydrostatic head (water resistance) while maximizing air passage. The question are air permeable membranes waterproof is critical; despite allowing air to flow, these membranes utilize complex multi-layer PP spunbond and functional film technology to remain completely watertight against rain and snow melt.

Frequently Asked Questions (FAQ)

1. Do air permeable membranes allow more heat to escape?

While they allow air to flow, the rate is strictly controlled to prevent significant heat loss. When installed correctly within a "sealed" roof system, the thermal benefits of keeping the insulation dry far outweigh any minor convective loss.

2. Can I use an air permeable membrane with a tight-fitting roof covering like metal?

Yes, but it is highly recommended to use a counter-batten to create a clear drainage and airflow path between the air permeable breather membranes and the metal sheets to prevent underside corrosion.

3. Does Jiangsu Aotelong provide BBA-certified products?

Yes. Our waterproof breathable membrane products have passed both European CE and British BBA certifications, ensuring they meet the highest standards for the UK and European roofing markets.

4. What is the difference between high and low permeability membranes?

A high-permeability waterproof breathable membrane has a much lower Sd-value (vapor resistance), typically < 0.05m, making it safer for cold roofs compared to low-permeability versions which may still require additional ventilation.

5. Can air permeable membranes be used in agricultural buildings?

Absolutely. They are excellent for agricultural building materials where high livestock density leads to high internal humidity, requiring rapid moisture dispersal to protect the roof structure.

Industry References

- BS 5250: Management of moisture in buildings — Code of practice.

- BBA (British Board of Agrément): Technical Requirements for Breather Membranes in Cold Pitched Roofs.

- ICC-ES AC188: Acceptance Criteria for Roof Underlays.

- Technical Data Repository: Jiangsu Aotelong New Materials Co., Ltd. (2025-2026 Edition).

日本語

日本語 Русский

Русский España

España عرب .

عرب .