Comparing waterproof air permeable membrane for roof: Air‑Permeable vs Traditional Impermeable Underlays

2025-11-12

In modern roof construction and refurbishment, choosing the correct type of underlay or membrane is critical to long‑term performance, condensation control, and overall building durability. This article explores the concept of a waterproof air permeable membrane for roof, and compares it against a traditional impermeable underlay system. We will evaluate performance criteria, installation and maintenance considerations, and help you make informed decisions. In doing so, we will integrate long‑tail keywords such as waterproof air‑permeable roof underlay membrane installation, high‑permeability waterproof breathable membrane for pitched roofs, air‑permeable waterproof membrane vs traditional impermeable roof underlay, benefits of waterproof breathable air‑permeable roof membranes in condensation control, and how to choose waterproof air‑permeable membrane for roof enclosure systems naturally throughout the discussion.

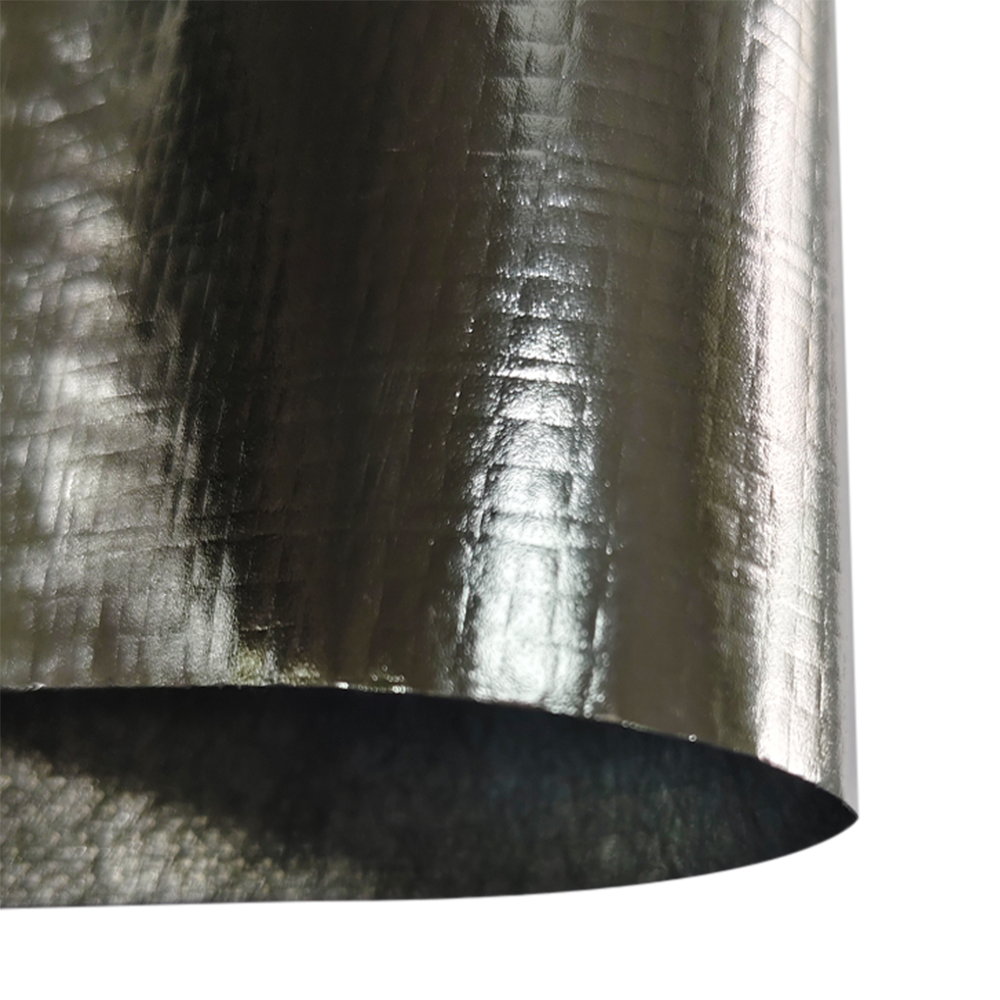

Black Multilayer Composite Reflective Film AWN140

What is an Air‑Permeable Waterproof Roof Membrane?

2.1 Definition and Function

- An air‑permeable waterproof roof membrane is a material installed under the outer roof covering that provides a water‑resistant barrier while allowing air and moisture vapour to pass through the underlay plane.

- This type of product enables the roof system to breathe, reducing the risk of trapped moisture, internal condensation and timber decay.

- When you plan a waterproof air‑permeable roof underlay membrane installation, you are selecting a product and technique designed for moisture management rather than simply blocking water.

- One key decision point is how to choose waterproof air‑permeable membrane for roof enclosure systems based on project needs.

2.2 Key Performance Criteria

- Vapour permeability and air permeability — allowing internal moisture to escape whilst preventing liquid water ingress.

- Water resistance — the membrane must perform as a waterproof barrier.

- Condensation control — by enabling moisture egress, the risk of mould, damp and rot is lowered.

- Compatibility with roof structure (pitch, batten spacing, outer covering).

- Installation environment and ventilation interplay — modern air‑open membranes aim to reduce the reliance on conventional ridge/eave ventilation.

What is a Traditional Impermeable Roof Underlay?

3.1 Definition and Typical Use

- A traditional impermeable roof underlay (often bituminous felt or impermeable film) is designed primarily to block water ingress, with minimal vapour and air transfer.

- It has been the standard in many older pitched roof systems for decades.

3.2 Advantages and Limitations

- Advantages: established materials, lower upfront cost, simple specification.

- Limitations: low or negligible vapour permeability, higher risk of moisture being trapped beneath the covering and within the roof deck.

- In scenarios with inadequate ventilation or high internal moisture, traditional impermeable underlays may lead to condensation, timber degradation, and loss of insulation effectiveness.

Air‑Permeable vs Traditional Underlays – A Comparative Analysis

4.1 Performance Comparison

The following table summarises the key properties and differences between an air‑permeable waterproof underlay and a traditional impermeable underlay.

| Property | Air‑Permeable Waterproof Membrane | Traditional Impermeable Underlay |

| Vapour/air permeability | High (allows internal moisture egress) | Very low (traps vapour) |

| Water ingress protection | High (water‑resistant) | High (water‑resistant) |

| Condensation risk | Low (due to vapour egress) | Higher (if ventilation inadequate) |

| Ventilation requirement | Reduced ventilation may be acceptable with air‑open membrane | Conventional ventilation mandatory (eaves + ridge) |

| Installation complexity | Requires attention to laps, compatibility with batten spacing and outer covering. | Relatively simpler but ventilation must be robust. |

| Typical lifespan/maintenance | Longer lifespan if moisture managed; less re‑roofs due to rot or hidden damage. | Shorter effective lifespan if condensation/rot occurs. |

4.2 Installation and Construction Considerations

- When planning a waterproof air‑permeable roof underlay membrane installation, verify the roof structure for ventilation adequacy, batten spacing, and compatibility with the selected membrane.

- Air‑permeable systems may allow simpler or reduced mechanical ventilation, but this depends on product certification and local building regulations.

- Traditional systems rely heavily on correctly designed ventilation paths; any blockage or mis‑installation can undermine performance.

- Consider project type: for refurbishment projects or irregular roof geometry, the flexibility of air‑permeable membranes (especially for complex roof lines) may be advantageous.

4.3 Maintenance and Lifespan Differences

- Air‑permeable membranes help maintain dry roof decks, which supports insulation performance, timber durability and overall envelope health.

- Traditional underlays may experience hidden damage if moisture accumulates; deterioration of underpinning structure may lead to earlier intervention.

- Selecting a product with certification and proven performance (for example, meeting equivalent to BBA or CE standards) is critical for lifespan integrity.

Why Choose a High‑Permeability Waterproof Breathable Membrane for Pitched Roofs?

When your project involves a pitched roof, especially in climates prone to moisture variability, internal atmospheric humidity, or limited roof ventilation, a high‑permeability waterproof breathable membrane for pitched roofs offers distinct advantages:

- Superior moisture management during the "drying‑out" phase of construction or refurbishment.

- Helps maintain consistent insulation performance, as trapped moisture would degrade thermal resistance.

- Better suited to modern airtight building envelopes where internal air‑tightness reduces cross ventilation, making a breathable underlay more beneficial.

- Greater design flexibility in complex roof geometries (e.g., dormers, skylights, lean‑to attachments) — the membrane's vapour or air permeability mitigates condensation risk without bulky ventilation interventions.

Case Application – Overview of Our Company's Capabilities

Located in Yangzhou City, Jiangsu Province — a major new materials industry base in the Yangtze River Delta of China — Jiangsu Aotelong New Materials Co., Ltd. (Zhongning New Materials Jiangsu Co., Ltd.) integrates R&D, production and sales to provide building enclosure materials including disposable medical materials, agricultural coverings, and crucially building membranes. Among its main offerings are low‑permeability waterproof breathable membranes and high‑permeability waterproof breathable membranes, as well as vapour barrier membranes and reflective insulation membranes.

The company's manufacturing scope also includes PP spunbond non‑woven fabrics, SMS, SMMS, SMMMS non‑woven fabrics, surgical gowns, protective clothing composite non‑woven fabrics. Certifications such as US ICC‑ES factory inspection and UK BBA factory inspection, as well as product certifications from the National Building Materials Testing Center, European CE and UK BBA for PP spunbond fabrics and waterproof breathable membranes, underline the technical competence and compliance focus of the company.

For architects, roofing contractors and building envelope engineers seeking to specify membranes that align with performance criteria for moisture control, condensation risk reduction and long‑term roof durability, the company's product lines support both "air‑permeable" and "traditional" use‑cases, facilitating both standard and advanced roofing solutions.

How to Specify and Install an Air‑Permeable Waterproof Roof Membrane

7.1 Specification Guide

- Assess roof slope, covering material (tiles, slates, metal), batten spacing and intended ventilation strategy.

- Identify the internal moisture load (occupancy, ventilation, building air‑tightness) to inform vapour/permeability requirements.

- Select membranes with documented performance parameters (e.g., vapour permeability, air open vs air‑open rating, water hold‑out) and certifications.

- Ensure compatibility with roof covering manufacturer requirements and local building regulation ventilation/condensation controls.

7.2 Installation Key Points

- Ensure correct overlap of membrane laps and seal edges per manufacturer instructions.

- Ensure batten fixation does not compromise integrity of the membrane; avoid excessive puncturing or stapling that weakens performance.

- Maintain the drainage path – ensure water does not pond under the membrane, and ensure eaves/gutter connections are secure.

- For air‑permeable membranes, although ventilation requirements may be reduced, it is still prudent to maintain adequate ventilation or ensure the membrane's certification supports minimal ventilation.

7.3 Common Pitfalls & Avoidance

- Assuming all breathable membranes relieve the need for ventilation — only some air‑open membranes are certified for ventilation‑free roof decks.

- Using an impermeable underlay in a roof structure with high internal moisture and limited ventilation — risk of condensation increases significantly.

- Ignoring manufacturer instructions for lap, fixings and exposure time — incorrect installation may offset the advantages of a high‑performance membrane.

Summary and Recommendations

In summary, a waterproof air permeable membrane for roof provides a modern, high‑performance alternative to traditional impermeable underlay systems. The key benefits are enhanced moisture/condensation management, improved durability of roof structure and insulation, and in many cases reduced reliance on complex ventilation systems. When specifying roofing underlays, careful attention to performance parameters, project conditions (ventilation, slope, geometry, internal moisture load) and installation practices is essential.

For new builds, re‑roofing or refurbishment — especially in climates or building types where internal moisture and ventilation are constrained — selecting a **high‑permeability waterproof breathable membrane for pitched roofs** is often the prudent choice. On more conventional roofs with robust ventilation and lower internal moisture loads, a traditional underlay may remain viable if correctly installed and maintained.

Ultimately, leveraging a company such as ours, with proven R&D, certifications and product lines that support both low‑ and high‑permeability waterproof breathable membranes, allows clients to match the right membrane technology to their roof enclosure system needs.

FAQ

- Q1: What is the main difference between an air‑permeable waterproof roof membrane and a traditional impermeable underlay?

- A: The primary difference is that the air‑permeable membrane allows internal moisture vapour and air to pass out of the roof assembly while still blocking liquid water, whereas a traditional impermeable underlay resists water but largely traps vapour and air inside, increasing the risk of condensation.

- Q2: Can I use a waterproof air permeable membrane and eliminate roof ventilation completely?

- A: Not always. Only those membranes certified as truly air‑open and vapour‑permeable may reduce or eliminate the need for ridge/eave ventilation. It is essential to check the product certification and project conditions.

- Q3: How do I choose the right membrane for my pitched roof project?

- A: You should evaluate roof slope, covering material, batten spacing, internal moisture load, ventilation strategy, and performance data of the membrane. Match the project to a suitable product specification (for example using our company's high‑permeability waterproof breathable membrane product line).

- Q4: Are air‑permeable membranes more expensive than traditional underlays?

- A: Generally yes, the material cost may be higher, but when you factor in the longer lifespan, reduced condensation risk, improved insulation performance and fewer maintenance issues, the lifecycle cost can be lower.

- Q5: What are common installation mistakes with air‑permeable membranes?

- A: Common mistakes include incorrect laps or fixings, puncturing the membrane excessively, failing to coordinate batten spacing or tile type, and assuming ventilation isn't needed when it is — all of which can compromise performance.

日本語

日本語 Русский

Русский España

España عرب .

عرب .