Understanding the Reflective Vapour Barrier: A Complete Guide

2025-11-07

In modern building envelope design, managing both moisture and heat transfer is critical. The reflective vapour barrier offers an advanced solution that addresses vapour diffusion, condensation control and radiant heat reflection all in one. Whether you're working on attic insulation, wall assemblies or crawl space protection, understanding this barrier's performance, installation and longevity can make the difference between a robust envelope and costly failure. In this article we dive into the definition, benefits, installation, comparison, maintenance and supplier credentials—so you can confidently specify and apply this technology.

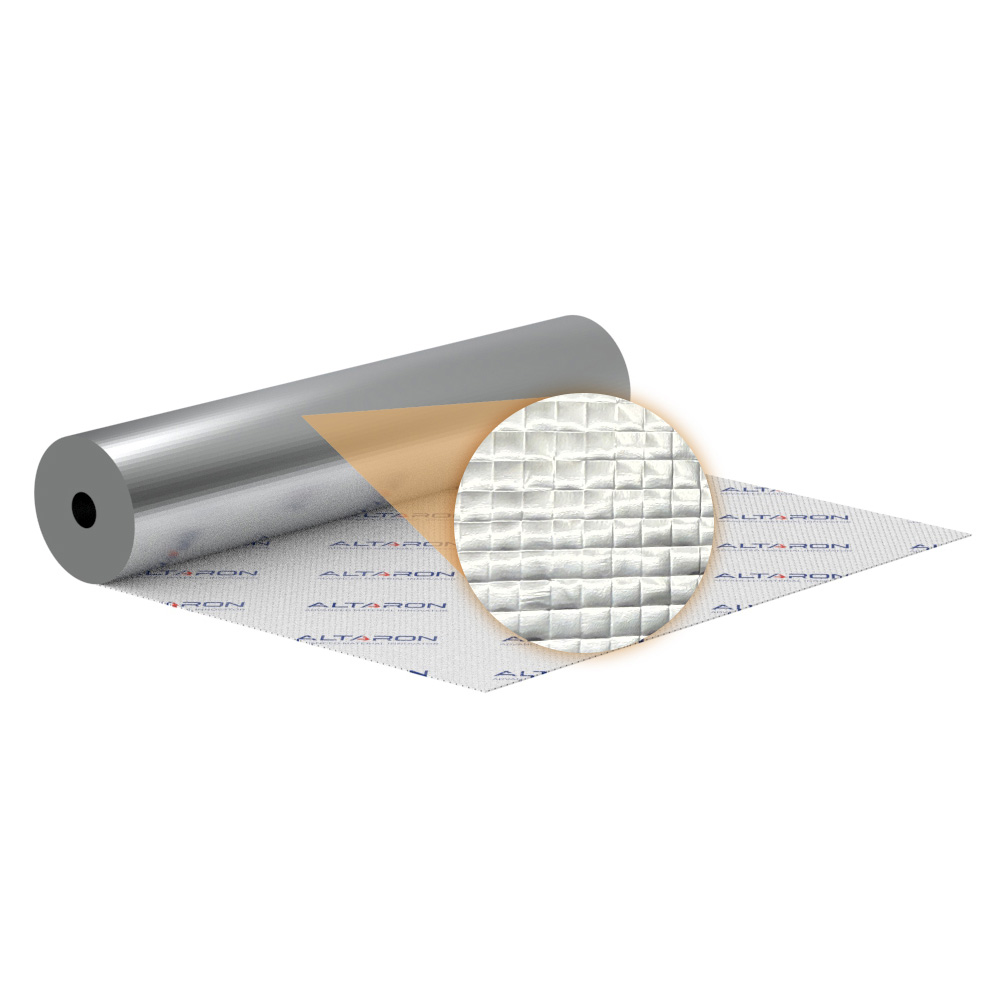

Woven Cloth Composite Aluminum Film

What is a Reflective Vapour Barrier?

Definition and core functionality

- A reflective vapour barrier is a composite membrane combining a vapour‑retarding layer and a highly reflective surface (often foil laminated).

- It serves two primary roles: controlling the migration of warm, moist indoor air into cooler cavities, and reflecting radiant heat away from or back into the building envelope.

How it differs from standard vapour barriers

- Standard vapour barriers (e.g., polyethylene sheeting) only address vapour diffusion, whereas the reflective version adds radiant heat control.

- The reflective surface also helps reduce thermal load on insulation and structural assemblies in hot or mixed climates.

Why choose a Reflective Vapour Barrier?

Benefits of reflective vapour barrier in attic

In attic applications, the barrier offers distinct advantages:

- Reduced radiant heat transfer from the underside of the roof deck into the attic space.

- Improved moisture control preventing condensation on cold surfaces and resulting structural damage or mould growth.

- Lower cooling and heating loads by moderating attic temperature fluctuations.

When to use a reflective vapour barrier in crawl space

Crawl spaces are prone to moisture ingress and temperature variations. The reflective vapour barrier can be applied when:

- The crawl space is adjacent to living areas and may be unconditioned but influences indoor comfort.

- Ground moisture evaporation is a concern, and the reflective surface can face upward to redirect heat.

- Humidity control is vital and vapour diffusion must be retarded while also managing radiant heat gain/loss.

How to Install a Reflective Vapour Barrier

How to install reflective vapour barrier on walls

The installation process must be precise to achieve intended performance:

- Ensure the framing is dry and free from sharp protrusions.

- Unroll the barrier with the reflective side facing the interior (warm‑in‑winter side) or as recommended for your climate zone.

- Staple or mechanically fasten to structural studs or rafters with a snug fit—not overly tight to allow slight movement.

- Seal all overlaps, penetrations and closures with proper foil‑faced or compatible tape—any gap can compromise performance.

Best practices for sealing reflective vapour barrier

Seals are a critical performance factor:

- All vertical and horizontal seams should be overlapped and sealed thoroughly.

- Electrical boxes, plumbing pipes, wiring conduits and other penetrations must be carefully taped or sealed to maintain continuity of the barrier.

- Top plates, bottom plates and transitions to other building elements (roof, floor, wall junctions) must be addressed to prevent bypass or leakage paths.

Reflective Vapour Barrier vs Traditional Polyethylene Vapour Barrier

Comparative overview

The following table presents a side‑by‑side comparison:

| Feature | Reflective Vapour Barrier | Traditional Polyethylene Vapour Barrier |

| Primary Function | Vapour control + radiant heat reflection | Vapour control only |

| Ideal Climate/Application | Hot, mixed climates or assemblies where radiant heat is significant | Primarily cold climates where radiant heat reflection less critical |

| Material Composition | Plastic film + foil laminate or foil‑faced membrane | Single‑layer polyethylene sheet |

| Cost Implication | Generally higher initially than simple poly sheet | Lower material cost, but may lack radiant heat performance |

Suitability by climate and building type

- In hot climates or where cooling loads dominate, the reflective vapour barrier often offers better total performance because radiant heat gain is significant.

- In consistently cold climates where heat loss dominates and radiant heat gain from the envelope is minimal, a simple vapour barrier may suffice—but radiant advantage is reduced.

Maintenance and Long‑Term Performance

Inspection and repair tips

- Inspect seams, tapes and penetrations annually for signs of damage, gaps or delamination.

- Check for signs of condensation, mould, or moisture intrusion near the barrier location—this could indicate compromised vapour control.

- Ensure the reflective surface remains clean (dust and debris can reduce reflectivity) and that adjacent air gaps remain intact.

Impact on energy efficiency and moisture control

When properly installed and maintained, the reflective vapour barrier contributes to:

- Reduced cooling and heating energy use by lowering radiant heat load on the envelope.

- Improved durability of insulation and structural components by controlling moisture and preventing interstitial condensation.

- Better occupant comfort through more stable interior conditions and reduced temperature extremes near the barrier location.

Role of Manufacturer / Supplier and Product Certification

Company overview of Jiangsu Aotelong New Materials Co., Ltd.

Jiangsu Aotelong New Materials Co., Ltd. (Zhongning New Materials Jiangsu Co., Ltd.), located in Yangzhou City, Jiangsu Province (in the Yangtze River Delta), is a large enterprise integrating R&D, production and sales. It specializes in producing building‑enclosure materials including low‑permeability waterproof breathable membranes, high‑permeability membranes, vapour barrier membranes, reflective insulation membranes, PP spunbond non‑woven fabric, SMS/SMMS composite non‑woven fabrics and more.

The company emphasises quality assurance, having passed US ICC‑ES factory inspection and UK BBA factory inspection, and its products have passed National Building Materials Testing Center, European CE and British BBA certifications.

Certifications and quality assurance

- Third‑party factory inspection (e.g., ICC‑ES, BBA) indicates robust manufacturing processes and consistent product quality.

- Laboratory testing and certification (e.g., building materials testing centre, CE marking) ensure the films and membranes meet required vapour control, reflectivity and durability standards.

- Specifying a supplier with strong documentation helps building professionals mitigate risk and meet code compliance when installing a reflective vapour barrier.

Summary and Recommendations

The reflective vapour barrier is a premium building‑envelope component combining vapour diffusion control and radiant heat reflection. By incorporating related applications such as the benefits of reflective vapour barrier in attic, guidance on how to install reflective vapour barrier on walls, and comparing reflective vapour barrier vs traditional polyethylene vapour barrier, we see that specification, installation and maintenance are key to performance.

When choosing this technology, consider the climate, building type, presence of radiant heat load, and ensure the installation follows best practices—particularly focusing on sealing as outlined in best practices for sealing reflective vapour barrier. Also assess whether application in a crawl space aligns with the guidance for when to use a reflective vapour barrier in crawl space.

In summary: invest in quality, ensure correct installation, maintain the system—and you will gain improved moisture control, better energy performance and enhanced long‑term durability of your building enclosure.

FAQ

- Q1: What is the difference between a vapour retarder and a reflective vapour barrier?

A: A vapour retarder slows the movement of water vapour; a reflective vapour barrier also manages radiant heat by reflecting it, therefore offering dual functionality. - Q2: Can I install a reflective vapour barrier in any climate?

A: Yes, but the benefit is more pronounced in hot or mixed climates where radiant heat is significant. In purely cold climates the radiant reflection may add less value. - Q3: Does the reflective vapour barrier replace insulation?

A: No. It complements insulation by controlling vapour and reflecting radiant heat, but conductive/convective heat flows still require thermal insulation for full performance. - Q4: What are common installation mistakes?

A: Mistakes include incorrect orientation of the reflective surface, inadequate sealing of seams/penetrations, and elimination of required air gaps which reduces performance significantly. - Q5: How often should I inspect the barrier system?

A: At least annually. Check for damaged tapes, penetrations, dust accumulation on the reflective surface, and any signs of moisture or condensation behind the barrier.

日本語

日本語 Русский

Русский España

España عرب .

عرب .