Engineering for Resilience: Stability and Thermal Aging of Waterproof Air Permeable Membranes

2025-12-12

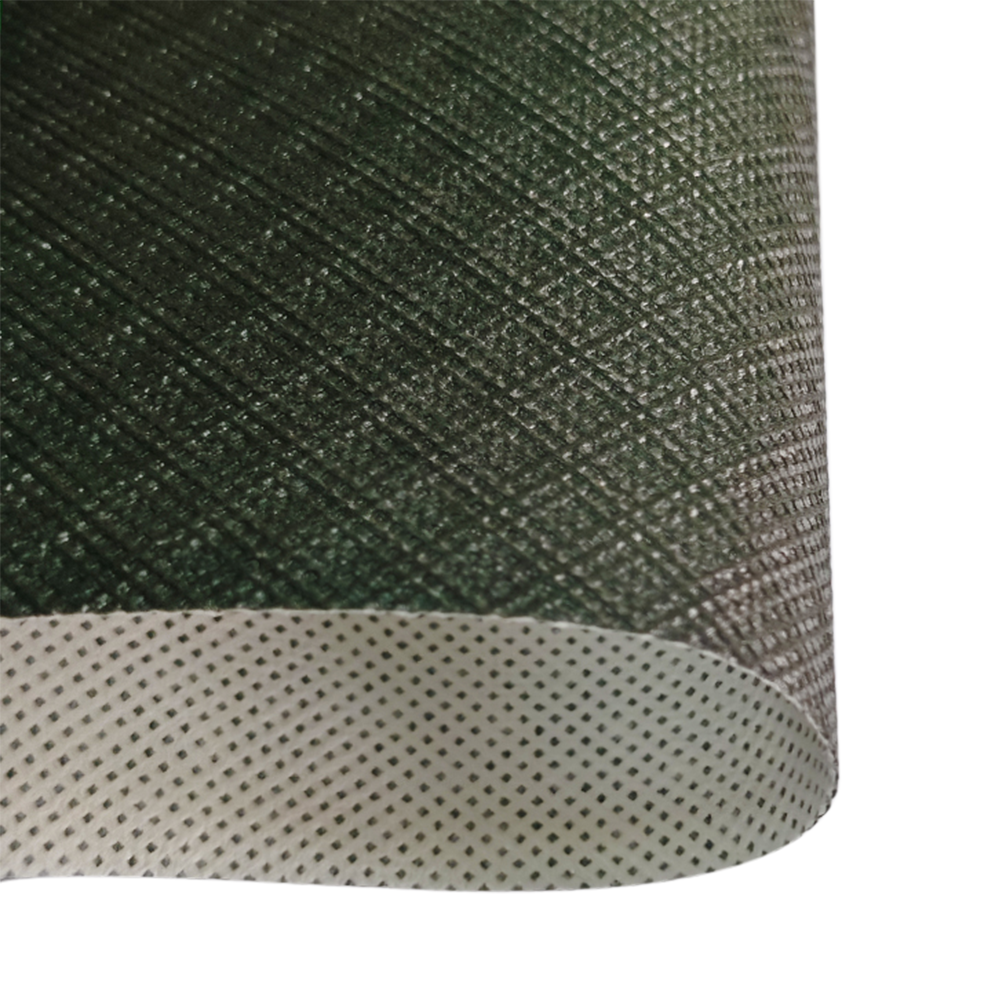

I. The Dual Mandate of Weather-Resistive Barriers

The **Waterproof Air Permeable Membrane** (or Water Resistive Barrier, often referred to as a breathable membrane) is a critical component of the modern building envelope, serving the dual function of protecting the structure from bulk water intrusion while allowing moisture vapor to escape. For construction professionals and B2B buyers, the primary concern is not just the initial performance, but the membrane's ability to maintain its physical integrity and vapor permeability throughout the construction process. This requires rigorous consideration of Ultraviolet (UV) stability and thermal aging performance, particularly during the temporary exposure period before final cladding or roofing is installed.

Jiangsu Aotelong New Materials Co., Ltd., located in the developed new materials industry base of the Yangtze River Delta, specializes in advanced building enclosure materials including high-permeability and low-permeability **Waterproof Air Permeable Membrane** and reflective insulation membrane. Our products meet stringent international standards, evidenced by successful factory inspections by the US International Code Council Evaluation Service and the UK British Board of Agrément, confirming our commitment to durable and compliant building solutions.

II. UV Degradation: The Challenge of Temporary Exposure

The structure of most **Waterproof Air Permeable Membrane** products is based on polyolefin layers (Polypropylene / Polyethylene), which are inherently susceptible to degradation from Ultraviolet (UV) radiation. UV light breaks down the polymer chains, leading to loss of tensile strength, embrittlement, and damage to the functional core (the breathable layer). This necessitates a certified **long-term UV exposure rating for roofing underlayment** and wall membranes.

The **waterproof breathable membrane temporary exposure limits** are a key specification, typically ranging from 30 days to 180 days. During this time, the membrane must withstand the cumulative solar radiation exposure without losing more than a defined percentage of its initial properties. Failure in this phase leads to costly re-wrapping and compromises the long-term effectiveness of the building envelope.

A. UV Stability Testing Protocol and Requirements

Compliance with **UV stability testing for weather resistive barrier** standards is essential. Accelerated weathering tests simulate real-world exposure by subjecting the material to intense UV light, high temperatures, and moisture cycling.

| Exposure Rating | Minimum Accelerated UV Hours (ASTM G154 equivalent) | Maximum Permissible Property Degradation (Typical) | Application Tolerance |

|---|---|---|---|

| 90-Day Temporary Exposure | 500 - 750 hours | Less than fifty percent Tear Strength Loss; Less than twenty-five percent Permeance Change | Residential/Small Commercial Construction. |

| 180-Day **Long-term UV Exposure Rating** | 1000 - 1500 hours | Less than forty percent Tear Strength Loss; Less than twenty percent Permeance Change | Complex Commercial Projects/Longer build schedules. |

III. Thermal Aging and Material Integrity

High surface temperatures, especially on unclad walls or under dark roofing materials during summer months, introduce significant **thermal aging effects on breathable membrane performance**. Temperatures can easily exceed seventy degrees Celsius (one hundred fifty-eight degrees Fahrenheit), causing accelerated oxidation, potential delamination of composite layers, and structural changes in the breathable film itself.

A. Maintaining Vapor Permeability (Permeance)

The most critical functional parameter is Permeance (measured in Perms or grams per square meter per twenty-four hours). Thermal cycling can cause polymer shrinkage or relaxation. In microporous membranes, this can result in the closing of the microscopic pores, leading to a significant, unacceptable drop in vapor permeability, thus trapping moisture within the wall cavity. Therefore, tests like the **accelerated weathering test for building membrane** must confirm that Water Vapor Transmission Rate is retained within specified limits after thermal stress.

B. Assessing Mechanical Degradation

Thermal and Ultraviolet exposure reduce the polymer's molecular weight, directly weakening the material. Tensile strength and tear strength retention are quantified metrics used to determine the degradation. For instance, a membrane rated for 6 months exposure must retain a minimum percentage of its initial tear strength to prevent damage during high winds or subsequent trades installation.

IV. Engineering Solutions for Enhanced Durability

To deliver a **Waterproof Air Permeable Membrane** with high **long-term UV exposure rating for roofing underlayment**, manufacturers must employ specialized additives. Hindered Amine Light Stabilizers (HALS) and UV absorbers are compounded directly into the polymer matrix, providing protection by scavenging free radicals and absorbing Ultraviolet energy before it can damage the polymer chains.

Our manufacturing expertise in Polypropylene spunbond non-woven fabrics and composite membranes allows us to formulate durable face layers that protect the sensitive functional film beneath. Differentiating between high-permeability and low-permeability **Waterproof Air Permeable Membrane** often involves adjusting the stabilizers and the specific thickness of the core film to balance vapor transmission with mechanical longevity.

A. **Accelerated Weathering Test for Building Membrane** vs. Real-World Exposure

Translating accelerated testing hours into real-world exposure is complex but necessary for accurate specification. Based on industry consensus and certification requirements, 1000 hours of **accelerated weathering test for building membrane** in a controlled chamber (e.g., QUV or Xenon-Arc) is often correlated to approximately 6 months of continuous exposure in a temperate climate zone, validating the **waterproof breathable membrane temporary exposure limits**.

V. Conclusion: Compliance and Reliability in Construction

The performance of the **Waterproof Air Permeable Membrane** during its temporary exposure on-site is a critical predictor of its long-term reliability. B2B buyers must prioritize products that demonstrate documented evidence of minimal degradation after **UV stability testing for weather resistive barrier** and thermal aging protocols. Jiangsu Aotelong New Materials Co., Ltd. provides certified, high-technology Water Resistive Barrier solutions, backed by international standards like the European Conformity mark and the British Board of Agrément, ensuring that our products offer the required resilience and stability for complex building enclosure systems.

VI. Frequently Asked Questions (FAQs)

Q1: How do UV stabilizers enhance the **Waterproof Air Permeable Membrane**'s performance?

- A: UV stabilizers, such as Hindered Amine Light Stabilizers (HALS), are blended into the polymer during manufacturing. They function by capturing free radicals that form when Ultraviolet light breaks polymer bonds, effectively slowing down the degradation process and extending the **waterproof breathable membrane temporary exposure limits**.

Q2: What is the primary **thermal aging effects on breathable membrane performance**?

- A: The primary thermal aging effect is the potential structural damage to the breathable film (especially microporous types). High heat can cause the polymer to shrink or relax, potentially closing the microscopic pores, which severely reduces the membrane's crucial water vapor permeability (Permeance).

Q3: What is the difference between a 90-day and a 180-day **long-term UV exposure rating for roofing underlayment**?

- A: The difference is the amount of cumulative Ultraviolet energy the material is guaranteed to withstand before critical properties (like tear strength and perm rating) degrade beyond specified limits. The 180-day rating requires the material to pass approximately double the hours of **accelerated weathering test for building membrane** compared to the 90-day rating.

Q4: Which property degrades fastest when the membrane is exposed to UV light?

- A: Tear strength (mechanical integrity) is often the first property to degrade significantly under Ultraviolet exposure. A loss of tear strength makes the **Waterproof Air Permeable Membrane** highly susceptible to damage during high winds or subsequent construction activity.

Q5: Why is the Permeance requirement more complex after aging than the initial **UV stability testing for weather resistive barrier**?

- A: After aging (both Ultraviolet and thermal), the permeance must not only be within specification but also be relatively stable. A membrane that maintains high tear strength but loses fifty percent of its initial permeability is considered a functional failure, as it severely compromises the moisture management of the wall or roof assembly.

日本語

日本語 Русский

Русский España

España عرب .

عرب .