Nonwoven Fabrics in Building Construction: Benefits and Applications

2025-09-25

The construction industry is constantly evolving, embracing innovative materials that enhance performance, durability, and sustainability. Among these, nonwoven fabric for building construction has emerged as a critical component, moving beyond its traditional roles to become a multifaceted solution for modern engineering challenges. These engineered fabrics, made from directed or randomly oriented fibers bonded by chemical, mechanical, heat, or solvent treatment, offer a unique combination of properties that synthetic woven materials often cannot match. This article delves deep into the world of nonwoven fabrics, exploring their fundamental benefits, diverse applications, and the specific value they bring to various construction projects, from massive infrastructure to residential buildings.

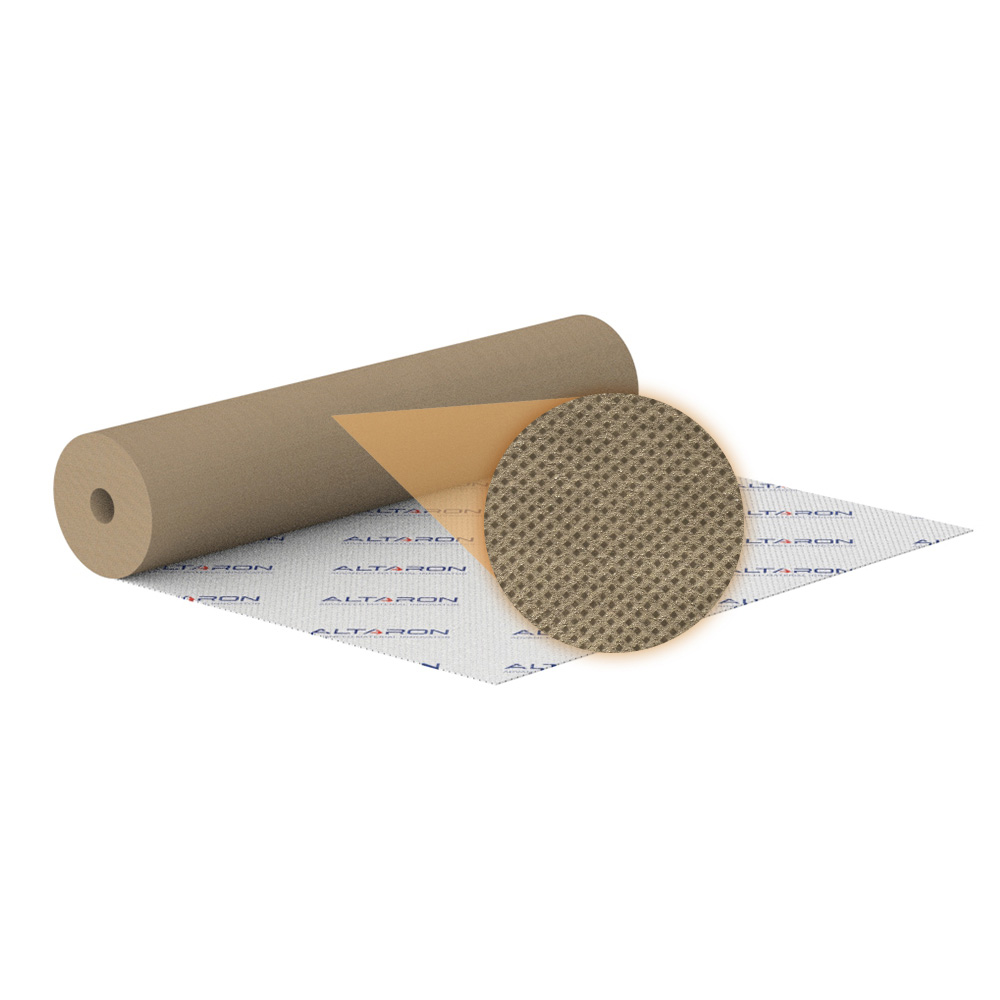

Non-woven Vapor Barrier Membrane NP120

What are Nonwoven Fabrics and Why are They Ideal for Construction?

Nonwoven fabrics are sheet-like materials made from long fibers, short fibers, or filaments, bonded together through a series of mechanical, thermal, or chemical processes. Unlike woven or knitted textiles, they are produced directly from a web of fibers, skipping the yarn production and weaving stages. This direct formation grants them a unique set of characteristics that make them exceptionally suitable for the demanding construction environment. Their structure can be precisely engineered to provide specific functionalities, such as high tensile strength, optimal permeability, or effective filtration, making them a versatile choice for engineers and architects seeking reliable and efficient material solutions.

- Customizable Properties: The manufacturing process allows for precise control over weight, thickness, density, and strength, enabling the creation of fabrics tailored for specific construction needs.

- Cost-Effectiveness: The high-speed, efficient production process of nonwovens often results in a lower cost per square meter compared to traditional woven geotextiles.

- Durability and Resistance: They exhibit excellent resistance to rot, mildew, chemicals, and UV radiation, ensuring long-term performance in harsh environmental conditions.

- Permeability: Their porous nature allows for the controlled passage of water and air, which is crucial for drainage and ventilation applications.

Key Benefits of Using Nonwoven Geotextiles in Construction

The adoption of nonwoven geotextile fabric advantages is primarily driven by the multitude of technical and economic benefits they offer. These materials act as workhorses on construction sites, performing vital functions that ensure the integrity and longevity of structures. Their primary roles include separation, filtration, drainage, protection, and reinforcement. By preventing the mixing of soil layers, allowing water to pass while retaining soil particles, and distributing loads more evenly, nonwoven geotextiles significantly enhance the performance of the soil and extend the life of construction projects, ultimately reducing maintenance costs and improving safety.

- Separation: They prevent the intermixing of distinct soil layers, such as subsoil and gravel, maintaining the structural integrity and drainage capacity of the base course.

- Filtration: Acting as a filter, they allow water to flow through while preventing the erosion of soil particles, a critical function in drainage systems and retaining walls.

- Drainage: Their three-dimensional fibrous structure provides in-plane water flow, dissipating hydrostatic pressure and reducing the risk of water damage.

- Reinforcement: When embedded in soil, they distribute loads over a wider area, increasing the bearing capacity of weak subgrades and improving slope stability.

Comparing Nonwoven and Woven Geotextiles

While both nonwoven and woven geotextiles are used in construction, they serve different purposes based on their inherent properties. The choice between them depends on the primary function required for the application. Nonwovens, typically made from polyester or polypropylene through a needle-punching process, excel in separation, filtration, and drainage roles due to their thicker, felt-like structure. Wovens, on the other hand, are characterized by their high tensile strength and low elongation, making them ideal for reinforcement applications where high load-bearing capacity is needed. Understanding this distinction is key to selecting the right material.

| Property | Nonwoven Geotextile | Woven Geotextile |

| Primary Function | Separation, Filtration, Drainage | Reinforcement, Stabilization |

| Tensile Strength | Moderate to High | Very High |

| Elongation | High | Low |

| Flow Rate (Permittivity) | High | Low to Moderate |

| Typical Structure | Felt-like, Random fiber orientation | Grid-like, Ordered yarns |

Top Applications of Nonwoven Fabrics in Modern Building Projects

The versatility of nonwoven fabrics allows them to be integrated into nearly every phase of a building project, from site preparation to the final roofing system. Their applications are a testament to their functional superiority in addressing common construction challenges. From acting as a protective cushion under hardscapes to serving as a critical component in green roof systems, these fabrics provide silent but essential support. The following list highlights some of the most significant and common applications of nonwoven fabric in construction, demonstrating their broad utility and indispensability in creating durable, efficient, and sustainable structures.

- Road and Pavement Construction: Used as a separator between the subgrade and base aggregate to prevent mixing and maintain drainage, thereby extending the road's service life.

- Drainage Systems: Employed in French drains, retaining wall drains, and landfill leachate systems to filter soil particles while allowing water to pass freely into perforated pipes.

- Erosion Control: Laid on slopes and embankments, they stabilize the soil until vegetation can be established, preventing soil loss from wind and water.

- Roofing Underlayment: Acts as a secondary weather-resistant barrier beneath tiles or shingles, providing protection against wind-driven rain and allowing moisture vapor to escape.

- Insulation Backing: Used as a facing material on insulation batts, it provides a vapor barrier and protects the insulation during handling and installation.

Roofing and Insulation: A Critical Use Case

In roofing systems, nonwoven fabrics play a multifaceted role that is crucial for both performance and energy efficiency. As an underlayment, they provide a critical line of defense against water infiltration that might get past the primary roofing material. Furthermore, in insulated buildings, these fabrics are integral to the performance of the insulation itself. They act as facings that not only protect the fragile insulation material but also manage vapor flow, preventing condensation within walls and roofs that can lead to mold growth and structural decay. This application is a perfect example of how a seemingly simple material contributes significantly to the building's durability and indoor air quality.

- Vapor Control: Acts as a vapor retarder to limit the movement of moisture-laden air into the building envelope.

- Protection: Shields batt and board insulation from physical damage during and after installation.

- Air Sealing: Helps reduce air leakage when properly sealed at seams, improving the overall energy efficiency of the structure.

Choosing the Right Nonwoven Fabric: A Guide for Construction

Selecting the appropriate nonwoven fabric for roofing and insulation or other construction applications is not a one-size-fits-all process. It requires a careful evaluation of the project's specific requirements, the soil conditions, and the intended function of the fabric. Key performance specifications must be considered to ensure the material will perform as expected over the long term. Ignoring these factors can lead to material failure, project delays, and increased costs. Therefore, consulting technical data sheets and, when necessary, a geotechnical engineer, is essential for making an informed decision that ensures project success and longevity.

- Identify the Primary Function: Determine if the main need is separation, filtration, drainage, protection, or reinforcement.

- Analyze Soil Conditions: Understand the soil type (e.g., clay, silt, sand) and its properties to select the correct fabric weight and apparent opening size (AOS).

- Review Technical Specifications: Pay close attention to key properties like grab tensile strength, puncture resistance, permittivity (flow rate), and UV resistance.

- Consider Long-Term Durability: Ensure the polymer composition (e.g., polypropylene, polyester) offers the required resistance to chemicals, pH, and long-term degradation for the site environment.

Understanding Key Material Specifications

To make an informed choice, one must understand the language of material specifications. These standardized test values provide a objective way to compare products and predict their performance in the field. For instance, tensile strength indicates how much load the fabric can bear before breaking, while permittivity measures its ability to allow water flow across its plane. The apparent opening size (AOS) is critical for filtration applications, as it indicates the size of particles that will be retained. Familiarity with these terms empowers contractors and engineers to select a fabric that is not just adequate, but optimal for the specific challenge at hand.

| Specification | What It Measures | Why It Matters |

| Grab Tensile Strength (ASTM D4632) | The force required to rupture a fabric sample. | Indicates ability to withstand stresses during installation and service. |

| Puncture Resistance (ASTM D4833) | Resistance to penetration by a plunger. | Predicts performance against sharp rocks or debris during backfilling. |

| Permittivity (ASTM D4491) | The rate of water flow through the fabric. | Crucial for drainage applications; a higher value means better flow. |

| Apparent Opening Size (AOS) (ASTM D4751) | The approximate largest particle that can effectively pass through the fabric. | Determines soil retention capability for filtration tasks. |

FAQ

What is the typical lifespan of nonwoven geotextile fabric in construction?

The service life of nonwoven geotextile fabric is a common concern for engineers planning long-term projects. When properly selected and installed based on the specific environmental and load conditions, high-quality polypropylene or polyester nonwoven geotextiles can have a lifespan exceeding 100 years. This exceptional durability is due to their inherent resistance to biodegradation, chemicals, and moisture. The key factors influencing longevity include exposure to UV radiation (before being covered), the pH of the surrounding soil, and the presence of specific chemicals or pollutants. Manufacturers often provide data on long-term design strength based on extensive testing, which should be consulted for critical applications.

Can nonwoven fabric be used for soundproofing in buildings?

Yes, nonwoven fabrics are highly effective for acoustic insulation and are a key component in modern sound insulation nonwoven material systems. Their dense, fibrous, and porous structure is excellent at absorbing sound energy and dampening vibrations. They are commonly used in interior wall cavities, floor assemblies, and ceiling systems to reduce airborne noise (like voices or TV sound) and impact noise (like footsteps). They are often made from recycled materials, adding a sustainability benefit. When compared to traditional materials, nonwoven acoustic panels offer superior performance at a lower weight and thickness, making them a preferred choice for architects designing for acoustic comfort in residential, commercial, and institutional buildings.

How does nonwoven fabric contribute to sustainable construction?

Nonwoven fabrics contribute significantly to sustainable building practices in several ways. Firstly, they enhance the durability and longevity of structures like roads and foundations, reducing the need for frequent repairs and reconstructions, which consume more materials and energy. Secondly, many nonwovens are made from recycled polymers (e.g., PET bottles), giving a second life to plastic waste. Furthermore, in applications like erosion control, they facilitate the growth of vegetation, which naturalizes and stabilizes the landscape. Their role in effective drainage and moisture management also helps prevent building deterioration, promoting healthier indoor environments and conserving the resources embodied in the building structure itself.

What is the difference between spunbond and meltblown nonwoven fabrics in construction?

Spunbond and meltblown are two prevalent manufacturing processes for nonwovens, resulting in fabrics with distinct properties. Spunbond nonwovens are created by extruding continuous filaments, laying them down in a web, and then bonding them. This process produces fabrics with high tensile strength and tear resistance, making them ideal for demanding applications like soil stabilization, roofing underlayments, and concrete curing blankets. Meltblown nonwovens, on the other hand, are made by extruding polymer through a die and using high-speed air to create extremely fine fibers. This results in a fabric with very small pores and a large surface area, excellent for filtration applications. Often, these processes are combined (e.g., SMS - Spunbond-Meltblown-Spunbond) to create fabrics with multiple functionalities, such as a strong substrate with a fine filtering layer.

Is nonwoven fabric easy to install on a construction site?

Absolutely. Ease of installation is one of the major nonwoven geotextile fabric advantages. The material is typically supplied in large rolls that are lightweight and manageable with common equipment. It can be unrolled directly onto the prepared subgrade. The installation process primarily involves unrolling, overlapping adjacent rolls by a specified amount (usually 12 to 18 inches), and securing the fabric with staples or pins on slopes to prevent movement during backfilling. No special tools or highly skilled labor are required, which helps keep project timelines and costs down. The key to successful installation is following the manufacturer's guidelines for overlap and securing to ensure continuous performance across the entire site.

日本語

日本語 Русский

Русский España

España عرب .

عرب .