Understanding Waterproof Breathable Membranes: Technology, Benefits, and Applications

2025-10-02

In the world of high-performance fabrics, the waterproof breathable membrane stands as a cornerstone technology. It's the invisible engine that keeps you dry and comfortable from the inside out, whether you're scaling a mountain or commuting in a downpour. This advanced material is engineered to solve a fundamental conflict: how to block external moisture like rain and snow while allowing internal moisture vapor (sweat) to escape. This article delves deep into the science, types, and practical considerations of these membranes, providing you with the knowledge to understand how they work and how to choose the right one for your needs. We will explore the key differences between ePTFE, PU, and TPU membranes, their ideal applications, and how to maintain them for long-lasting performance.

What is a Waterproof Breathable Membrane and How Does It Work?

A waterproof breathable membrane is a thin, porous film laminated or coated onto a textile to provide protection against liquid water while permitting water vapor to pass through. The magic lies in its micro-structure. The pores in these membranes are thousands of times smaller than a water droplet but hundreds of times larger than a water vapor molecule. This size differential is the key to its dual functionality. The primary mechanisms at play are micro-porous and hydrophilic (monolithic) technologies, which we will explore in detail later. Understanding this basic principle is the first step in appreciating the engineering behind modern outdoor and workwear.

- Hydrostatic Head: This is the primary metric for waterproofing. It measures the water column (in millimeters) the fabric can support before water penetrates. A rating of 10,000mm is considered excellent for most outdoor activities.

- Moisture Vapor Transmission Rate (MVTR): This measures breathability, or how many grams of water vapor can pass through a square meter of the fabric over 24 hours. Higher numbers indicate better breathability.

- Durability: The membrane's resilience to abrasion, oils, and detergents is crucial for its lifespan. Some membranes are more durable than others, affecting their suitability for different environments.

The Science of Keeping Dry: Micro-porous vs. Hydrophilic Membranes

The technology behind membranes falls into two main categories, each with a distinct method for achieving the same goal. The choice between them often involves trade-offs between performance, durability, and cost.

- Micro-porous Membranes: These contain billions of microscopic pores per square centimeter. These pores are permanently open, providing a physical barrier to liquid water while allowing vapor molecules to pass through freely. They typically offer excellent, instant breathability.

- Hydrophilic (Monolithic) Membranes: These are non-porous. Instead, they use a chemistry-based process. The membrane's polymer chains attract water vapor molecules on the inside (high humidity), which then diffuse through the membrane to the outside (lower humidity) where they are released. They are generally less prone to clogging from contaminants like body oils.

Comparing Membrane Technologies

The following table provides a clear comparison of the two primary membrane technologies to help you understand their core differences.

| Feature | Micro-porous | Hydrophilic |

| Mechanism | Physical pores block water, allow vapor | Chemical absorption and diffusion of vapor |

| Breathability | Excellent, immediate | Good, can be temperature/humidity dependent |

| Durability | Can be susceptible to clogging from oils and detergents | Generally more resistant to clogging and contaminants |

| Common Materials | ePTFE (expanded Polytetrafluoroethylene) | PU (Polyurethane), TPU (Thermoplastic Polyurethane) |

Key Types of Waterproof Breathable Membranes: ePTFE, PU, and TPU

While the underlying science categorizes membranes as micro-porous or hydrophilic, they are most commonly known by their material composition. The three most prevalent types are ePTFE, PU, and TPU, each offering a unique set of properties. Understanding the difference between ePTFE and PU membrane is a common point of confusion for consumers, and rightfully so, as the performance gap can be significant.

- ePTFE (expanded Polytetrafluoroethylene): This is a micro-porous membrane famous for its exceptional breathability and waterproofness. It's the technology behind many high-end brands. It is incredibly lightweight and efficient but can be more delicate and requires an oleophobic (oil-hating) treatment to prevent contamination.

- PU (Polyurethane): This is a versatile hydrophilic membrane. It is often applied as a coating and is known for its good balance of performance, durability, and cost-effectiveness. It is highly resistant to clogging, making it a reliable choice for a wide range of applications.

- TPU (Thermoplastic Polyurethane): TPU membranes are a subtype that offers enhanced durability, elasticity, and resistance to extreme temperatures compared to standard PU. They are often used in more demanding environments and products where flexibility is key.

How to Choose the Right Membrane for Your Jacket

Selecting the right membrane isn't about finding the "best" one, but the best one *for you*. Your choice should be guided by the specific activities and conditions you expect to encounter. A key question to ask is, how to choose waterproof breathable membrane for my jacket based on my intended use? The answer lies in balancing the performance metrics with your personal needs and budget.

- Activity Level: High-output activities like ski touring or trail running demand the highest breathability (often found in ePTFE). For casual hiking or urban use, a robust PU membrane may be perfectly sufficient.

- Climate and Conditions: Cold, dry environments are less demanding on breathability than warm, wet ones. In humid conditions, a membrane's ability to manage vapor is pushed to its limits.

- Durability Needs: If your jacket will face abrasion from a backpack or work equipment, a more durable TPU or densely woven fabric-laminated membrane is advisable.

- Budget: ePTFE technologies typically command a premium, while PU and TPU options offer excellent performance at a more accessible price point.

Beyond Jackets: Applications in Construction and Roofing

The utility of waterproof breathable membrane technology extends far beyond the realm of apparel. In the building industry, these materials are critical components for creating healthy, durable, and energy-efficient structures. A waterproof breathable membrane for roofing is a prime example, where it serves as a weather-resistant barrier that protects the building envelope.

- Roofing Underlayment: Installed beneath the final roofing material (like tiles or shingles), these membranes prevent wind-driven rain from entering while allowing trapped moisture within the roof structure to escape, preventing rot and mold.

- Wall Construction: Used within wall assemblies, they act as a housewrap, protecting the insulation and structural frame from external moisture while letting interior vapor diffuse outwards.

- Benefits of Breathable Construction Membranes: The primary advantage is the preservation of the building's structure. By allowing moisture to escape, these membranes prevent the buildup that can lead to wood decay, insulation failure, and unhealthy indoor air quality caused by mold and mildew.

Maintaining Your Gear: Washing and Re-DWR Treatment

The performance of a garment with a waterproof breathable membrane is not solely dependent on the membrane itself. The outer fabric is treated with a Durable Water Repellent (DWR) finish, which causes water to bead up and roll off. Over time, this DWR wears off, and the membrane can get clogged with dirt and body oils, leading to a phenomenon known as "wetting out." This is when the outer fabric becomes saturated with water, making the garment feel cold, heavy, and less breathable, even though the membrane itself is still waterproof. Therefore, knowing the best way to wash waterproof breathable jacket is essential for longevity.

- Use Technical Detergent: Always use a specific, technical wash-in detergent designed for waterproof gear. Avoid standard detergents and fabric softeners, as they contain additives that can clog the membrane's pores and strip the DWR coating.

- Wash on a Gentle Cycle: Use a warm, gentle wash cycle and rinse twice to ensure all soap residues are removed.

- Re-apply DWR: After washing and drying (on a low heat tumble dry, which can help reactivate some DWR), it is often necessary to apply a spray-on or wash-in DWR treatment to restore the water-beading performance of the outer fabric.

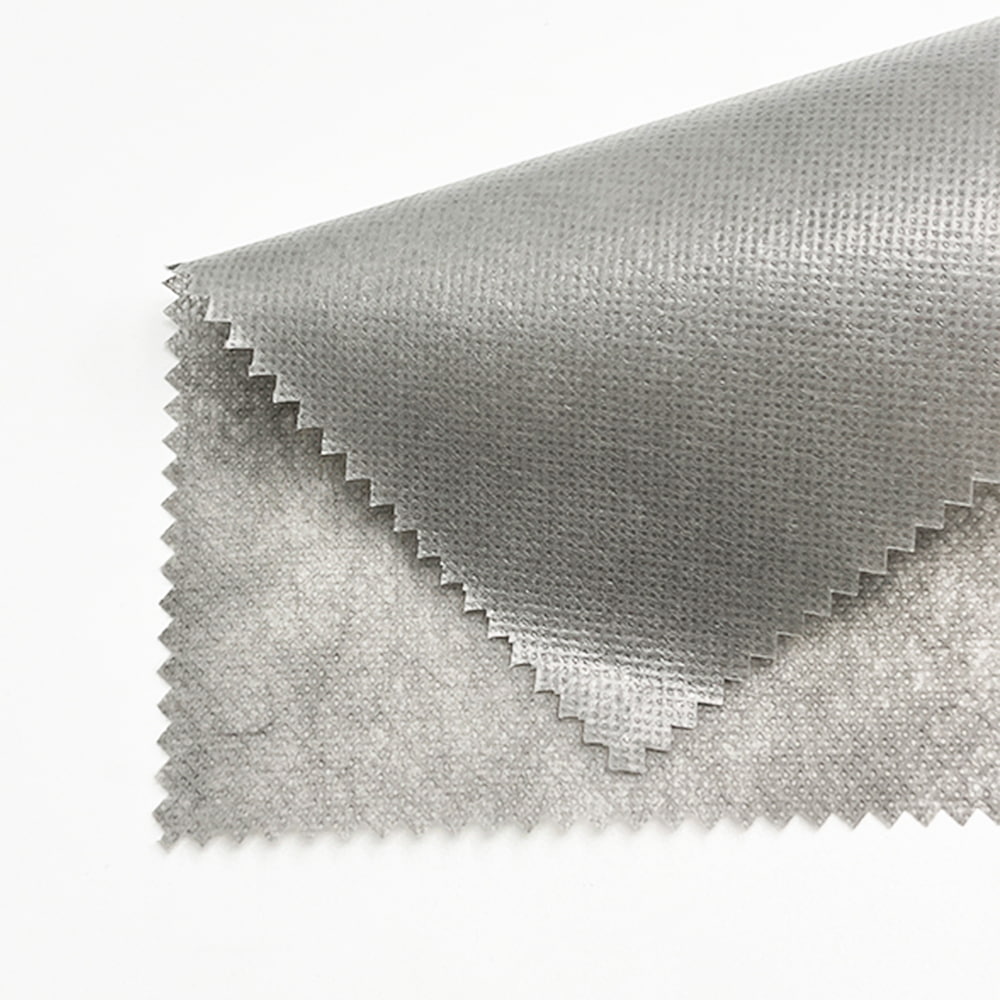

80g~260gsm PP Non-woven Compound Breathable Film Three-layered Roofing Membrane

FAQ

What is the difference between waterproof/breathable and water-resistant?

This is a fundamental distinction. Waterproof/breathable describes a material, like a waterproof breathable membrane, that is engineered to completely prevent liquid water from passing through (as measured by a high hydrostatic head rating) while also allowing water vapor to escape. A water-resistant material, on the other hand, can only repel light moisture for a short period. It lacks a membrane and will eventually saturate and wet through under sustained rain or pressure. Waterproofness is a binary state—either it is waterproof or it isn't—whereas water resistance is a measure of how long it can hold out.

Can a waterproof breathable membrane actually "wear out"?

The membrane itself is very durable and does not typically "wear out" in the sense of dissolving. However, its performance can be severely degraded over time. The two main causes are physical contamination (body oils, dirt, sunscreen clogging the pores of a micro-porous membrane) and the degradation of the DWR coating on the outer fabric. When the DWR fails, the outer fabric "wets out," creating a layer of cold water on the outside that hinders the vapor pressure gradient needed for breathability, making the garment feel clammy and non-breathable. Proper care, as outlined in this article, is the key to maintaining the membrane's functionality for years.

Is a higher MVTR rating always better?

While a higher Moisture Vapor Transmission Rate (MVTR) generally indicates better breathability, it's not the sole factor to consider. Lab test conditions vary significantly, and a number from one test method cannot be directly compared to a number from another. Furthermore, real-world performance is influenced by the entire garment system—the outer fabric, liners, and layers worn underneath. A membrane with a very high MVTR in a garment with a non-breathable outer fabric will not perform well. It's more effective to look at the overall construction and intended use of the garment and use MVTR as a comparative guide within a single brand's product line or when the test method is specified.

How does temperature affect membrane breathability?

Temperature has a significant impact, particularly on hydrophilic membranes. Breathability relies on a difference in humidity and temperature between the inside and outside of the garment. Hydrophilic membranes, which operate on a diffusion process, are often more effective with a greater temperature gradient (i.e., when it's much colder outside than inside). In warm, humid conditions where the temperature and humidity differential is low, all membranes struggle, but micro-porous types may have a slight advantage as they rely less on a chemical gradient and more on physical pores for vapor transfer.

日本語

日本語 Русский

Русский España

España عرب .

عرب .