Nonwoven Roofing Underlayment: The Cornerstone of Modern Roof Protection

2025-08-14

Nonwoven roofing underlayment plays a vital role in modern construction, serving as the second line of defense beneath roofing shingles or metal panels. Functionally, it has evolved from a simple waterproof layer into a high-performance roofing protection system that integrates waterproofing, breathability, high strength, and lightweight properties. It effectively addresses challenges posed by climate change, such as extreme rainfall, strong winds, and sun exposure, ensuring the building's interior remains safe from moisture intrusion and extending the lifespan of the entire roof structure and building.

Comparison of Traditional vs. Nonwoven Underlayment

To better understand the advantages of nonwoven roofing underlayment, let's compare it with traditional asphalt felt underlayment:

| Feature | Nonwoven Roofing Underlayment | Traditional Asphalt Felt |

|---|---|---|

| Weight | Extremely light, typically tens to hundreds of grams per square meter | Heavier, often several to ten times more |

| Tear Resistance | Excellent; high-strength fiber structure makes it difficult to tear or damage | Poor; prone to tearing during installation or from wind forces |

| Breathability | Excellent; allows water vapor to escape, preventing internal condensation | Poor; airtight, which can lead to moisture and mold inside the roof |

| Waterproofing | Superior; surface is specially treated for reliable waterproofing | Good, but becomes brittle and cracks with age, reducing waterproofing |

| Installation Speed | Fast; lightweight rolls can be handled by one person without special equipment | Slow; heavy and stiff rolls often require multiple people to install |

| Lifespan | Long; resistant to UV and temperature changes, lasting for decades | Short; susceptible to UV damage, becoming brittle and having a shorter lifespan |

| Eco-friendliness | Often made from recyclable polymers, making it more environmentally friendly | Contains asphalt and organic solvents, which have an environmental impact |

This comparison highlights that nonwoven roofing underlayment surpasses traditional materials in nearly all key performance indicators. Its lightweight design significantly reduces roof load and simplifies installation, while its superior tear resistance ensures integrity during both construction and use. Most importantly, its unique breathability solves the traditional "waterproof but not breathable" problem, effectively preventing moisture from accumulating and causing wood rot or insulation failure.

Core Technology and Performance of Nonwoven Roofing Underlayment

Nonwoven roofing underlayment has become a top choice for modern construction due to its unique core technology and excellent performance. It's not just a simple waterproof layer but a multifunctional system created through advanced nonwoven processes.

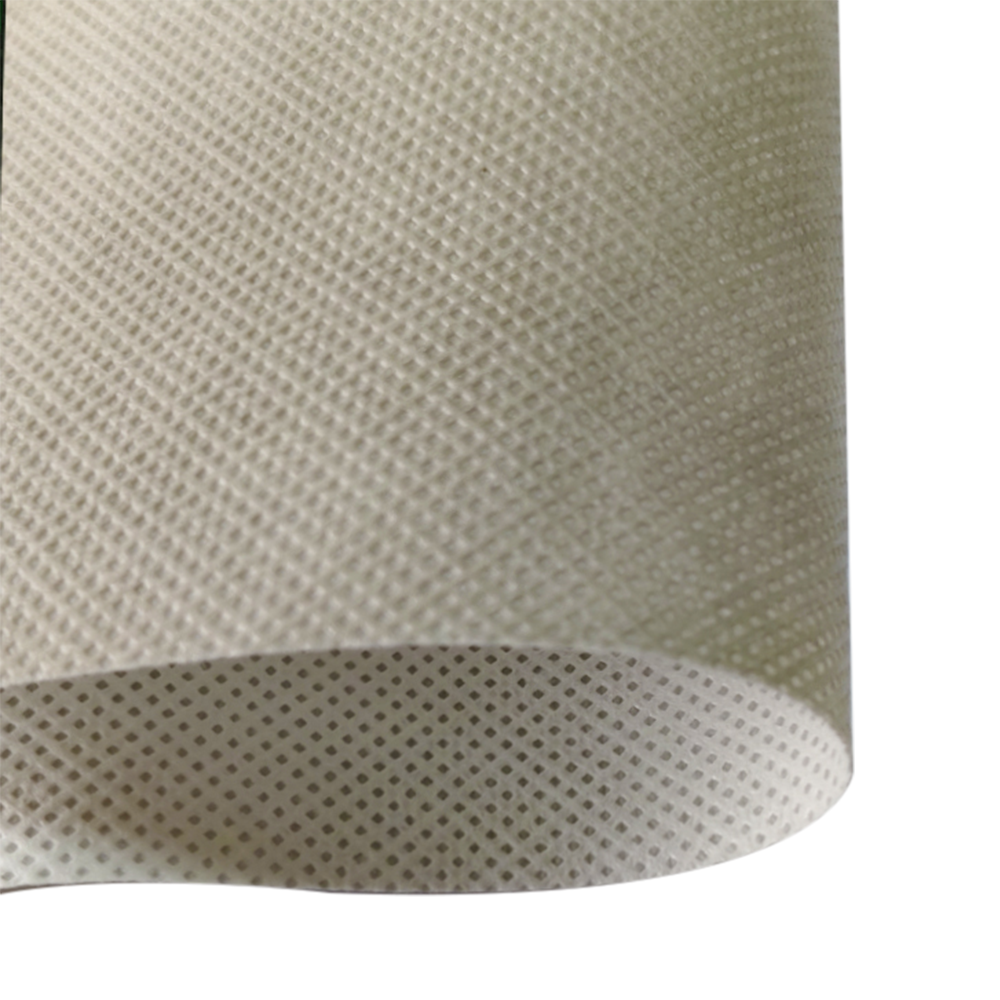

1. Material Composition and Nonwoven Technology

The core of nonwoven roofing underlayment is nonwoven fabric. Unlike traditional woven or knitted fabrics, nonwoven fabric is made by orienting or randomly arranging fibers, then bonding them through friction, adhesion, or chemical methods. This technology gives the material a high strength-to-weight ratio and allows for precise control over its breathability and waterproofing properties.

Common nonwoven materials include:

- Polypropylene (PP)

- Polyethylene (PE)

- Polyester

These polymers have excellent weather and durability resistance. The nonwoven process transforms them into a lightweight, high-strength fiber network, providing a solid foundation for further functional treatments.

2. Functional Features: Waterproofing, Breathability, and Durability

The most critical feature of nonwoven roofing underlayment is its unique "waterproof and breathable" capability, which is achieved through scientific design.

- Superior Waterproofing: The material's surface is often treated with a special coating or laminated film, creating a dense waterproof layer that effectively blocks liquid water (rain, melted snow) from penetrating. This serves as a secondary defense even if the roof's primary covering is damaged.

- Excellent Breathability: Unlike airtight asphalt felt, the nonwoven underlayment's microporous structure or composite membrane allows water vapor molecules to pass through. This enables moisture accumulated in the attic or insulation to escape, preventing condensation, mold, and wood rot. This "breathing" ability is key to the long-term health of the roofing system.

- High Strength and Durability: The nonwoven fiber network provides excellent tear resistance, which is crucial during installation to prevent accidental damage from foot traffic or nailing. It also has superior aging and UV resistance, maintaining its performance even when exposed to sunlight for an extended period before the final roofing material is installed.

3. Performance Parameter Comparison

To provide a more intuitive understanding of its performance, here is a comparison of different nonwoven roofing underlayment types:

| Performance Parameter | Standard Nonwoven Underlayment | High-Performance Nonwoven Underlayment | Traditional Asphalt Felt |

|---|---|---|---|

| Weight (g/m²) | approx. 100 - 140 | approx. 160 - 200 | approx. 1500 - 3000 |

| Tear Strength | Cross Direction: > 90 N Machine Direction: > 100 N | Cross Direction: > 150 N Machine Direction: > 200 N | Cross Direction: < 50 N Machine Direction: < 80 N |

| Water Vapor Permeability | High, typically > 10 Perms | Very High, typically > 20 Perms | Very Low, almost zero |

| UV Exposure Time | Can withstand 30-60 days | Can withstand 90-180 days | Not recommended for prolonged exposure |

| Temperature Range (°C) | -40 to +80 | -40 to +90 | 0 to +60 |

(*Note: These are general reference values; specific values vary by product.*)

From a parameter comparison, high-performance nonwoven underlayment has significant improvements across all metrics, especially in tear strength and UV exposure time, offering greater installation flexibility and safety. These core technologies and superior performances solidify nonwoven roofing underlayment's position as the cornerstone of modern roof protection.

A Comprehensive Guide to Waterproof Breather Membranes in Construction

In modern buildings, a waterproof breather membrane is a critical component of roof and wall systems. Its core function is to achieve the seemingly contradictory tasks of "waterproofing" and "breathability." It blocks external liquid water (rain, snow) from entering the building while allowing internal water vapor to escape. This prevents the building structure from becoming damp, moldy, and corroded, greatly improving its durability and the comfort of its occupants.

1. How It Works: Achieving Dual Functionality

The unique feature of a waterproof breather membrane lies in its microporous structure or high-tech composite layers. Its function is based on a simple physical principle: water vapor molecules are much smaller than liquid water molecules.

- Waterproofing: The membrane's surface has tiny pores or a special coating that forms a barrier to block liquid water molecules from passing through. When rain or melted snow hits the membrane, it beads up and cannot penetrate.

- Breathability: Due to temperature and humidity differences, water vapor can accumulate inside a roof or wall. These small vapor molecules can easily pass through the membrane's microporous structure and exit the building, preventing condensation, mold, and wood rot. This "one-way passage" is essential for the long-term health of the roofing system.

2. Performance Advantages of Nonwoven Materials in This Application

Nonwoven roofing underlayment is a primary form of waterproof breather membrane. Its exceptional performance makes it a leader in this field.

- High Strength and Durability: The nonwoven process provides the material with excellent tear and puncture resistance, ensuring it won't be easily damaged during installation and use.

- Lightweight and Easy to Install: Compared to traditional, heavy materials, nonwoven underlayment is light and flexible, making it easy to handle and lay down, which significantly boosts installation efficiency.

- Long-term Weather Resistance: It effectively resists UV radiation and temperature changes, so its performance remains stable even when exposed outdoors for an extended period before the final roofing material is installed.

3. Selection Guide and Parameter Comparison

Choosing the right waterproof breather membrane is crucial for the success of any roofing system. Here is a comparison of different types and key parameters to help you make an informed decision:

| Parameter | Single-Layer Microporous Membrane | Multi-Layer Composite Membrane | Traditional Breathable Felt (Paper-based) |

|---|---|---|---|

| Breathability | Good | Excellent | Poor; swells when wet |

| Waterproofing | Good | Excellent; high waterproof rating | Poor; softens and breaks down when wet |

| Tear Strength | Good | Excellent; multi-layer structure is stronger | Poor |

| UV Resistance | Fair | Excellent; can be exposed for longer periods | Very Poor; not resistant to sunlight |

| Application | Suitable for general climates | Suitable for extreme climates (cold, heavy rain) | Used only for temporary or simple structures |

| Ease of Installation | Easy | Easy, but requires careful sealing of seams | Easy, but easily damaged |

Breathability (Water Vapor Permeability): This is typically measured in "Perms" or "g/m²/24h." A higher value indicates better breathability.

Waterproofing (Water Head Pressure): Refers to the height of a column of water the membrane can withstand. A higher value means stronger waterproofing.

Tear Strength: Measures the material's resistance to tearing. High strength ensures stability during installation and for the roof system as a whole.

By considering these parameters, you can choose the most suitable nonwoven waterproof breather membrane for your project's specific needs, budget, and climate conditions.

Correct Application and Installation of Nonwoven Roofing Underlayment

The performance benefits of nonwoven roofing underlayment are only fully realized with correct application and installation. Improper installation can compromise its waterproof and breathable functions, potentially leading to premature failure of the entire roofing system. Proper steps and precautions are essential to ensure it acts as a robust protective barrier for the roof.

1. Pre-Installation Preparation

Thorough preparation is crucial before installing nonwoven roofing underlayment.

- Surface Cleaning: Ensure the roof deck (e.g., plywood or concrete) is flat, dry, and clean. Remove all nails, debris, dust, and oil to prevent damage to the underlayment or affect its flatness.

- Tool Preparation: Gather the necessary tools, including a tape measure, utility knife, staple gun or roofing nails, sealing tape, and safety equipment (e.g., harness, gloves).

- Material Inspection: Check the nonwoven underlayment roll for any damage. If any is found, the material should be replaced immediately.

2. Detailed Installation Steps

The correct installation process maximizes the underlayment's protective effects.

- From the Eaves: Installation should begin at the eave line, laying the first course of underlayment flat, ensuring the edge aligns with the eave line and allowing for an overhang to guide water away.

- Overlap Layers: The next course of underlayment should overlap the previous one. A horizontal overlap of 10-15 cm and a vertical overlap of 15-20 cm is generally recommended. Overlapping is key to ensuring continuous waterproofing and must be strictly followed.

- Fastening: Use a staple gun or roofing nails to secure the underlayment to the deck. The fasteners should be evenly distributed along the overlap edges and across the underlayment's surface. Avoid over-fastening.

- Special Areas: For roof penetrations like chimneys, vents, and skylights, the underlayment needs to be cut and specially treated. Typically, specialized sealing tape or additional small pieces of underlayment are used to seal these vulnerable points.

3. Installation Precautions

- Avoid Wrinkles: During installation, be sure to pull the underlayment flat, avoiding any wrinkles. Wrinkles can create areas where water might pool, affecting drainage and potentially leading to seepage.

- Weather Considerations: Installation should be carried out in clear, calm, or low-wind conditions. Strong winds can make the lightweight underlayment difficult to handle, increasing installation difficulty and risk. Do not install in rain or wet conditions.

- Temporary Protection: If the final roofing material cannot be installed immediately, the underlayment's temporary exposure period should follow its product parameters. While high-quality nonwoven underlayment has UV resistance, prolonged exposure to direct sunlight can still affect its performance.

4. Common Installation Errors and Solutions

| Common Error | Potential Consequences | Solution |

|---|---|---|

| Insufficient Overlap | Fails to create a continuous waterproof layer, allowing water to seep through gaps. | Strictly follow the manufacturer's recommended overlap width and use sealing tape for reinforcement. |

| Excessive Fastening | Creates too many small holes in the underlayment, potentially compromising waterproofing. | Distribute fasteners evenly, avoid overcrowding, and use fasteners with washers. |

| Installing on a Wet Deck | Moisture is trapped beneath the underlayment, leading to wood rot and mold. | Ensure the deck is completely dry before beginning installation. |

| Failing to Seal Penetrations | Waterproofing fails around chimneys and vents. | Use sealing tape or specialized flashing to tightly wrap and seal all penetrations. |

By following these proper application and installation guidelines, nonwoven roofing underlayment can truly fulfill its role as the cornerstone of modern roof protection, providing long-lasting and reliable defense for a building.

Long-Term Protection: The Value and Future of Nonwoven Roofing Underlayment

The value of nonwoven roofing underlayment extends far beyond its immediate waterproof and breathable functions. It represents a commitment to the long-term health and sustainability of a building. It enhances the overall performance of the roofing system, providing long-term protection, and shows great potential for future development.

1. The Long-Term Value of Nonwoven Roofing Underlayment

Nonwoven roofing underlayment significantly extends the life of a roof and a building. Its value is reflected in the following aspects:

- Protects the Roof Structure: By effectively venting moisture and blocking liquid water, it prevents wood rot, metal component corrosion, and moisture-induced failure of insulation, thus fundamentally protecting the building's "skeleton."

- Improves Energy Efficiency: Its breathability ensures that insulation remains dry and maintains its optimal thermal performance, reducing energy consumption for heating and cooling.

- Enhances Occupant Comfort: A roof free from moisture and mold provides a healthier and more comfortable indoor environment for occupants.

- Reduces Maintenance Costs: Due to its excellent durability and aging resistance, it reduces the need for frequent repairs and replacements, saving owners significant maintenance costs over time.

2. Future Development Trends of Nonwoven Roofing Underlayment

With increasingly stringent demands on building performance, the technology and application of nonwoven roofing underlayment are constantly advancing. Future development will likely include:

- Enhanced Performance Integration: Future products will not be limited to just waterproofing and breathability but will integrate more functions, such as higher puncture resistance, stronger UV resistance, or even self-healing or fire-retardant properties.

- Improved Eco-friendliness: As global attention on sustainable development grows, nonwoven underlayments will increasingly use recyclable or biodegradable materials to reduce their environmental impact.

- Smart Material Applications: Combined with IoT technology, future roof underlayments may embed sensors to monitor the roof's temperature, humidity, and structural health in real time, providing data for maintenance.

3. The Importance of Quality and Certification

Choosing a high-quality nonwoven roofing underlayment is crucial. This is not only related to the product's performance but also to the safety and durability of the entire building system. Reliable products typically pass strict international certifications and factory inspections, which are strong guarantees of product quality and performance.

For example, companies like Jiangsu Aotelong New Materials Co., Ltd. have products that have passed factory inspections from international authorities such as the US ICC-ES and the UK BBA. At the same time, the products themselves have received certification from the National Building Materials Testing Center, European CE certification, and British BBA certification. These certifications not only prove that the product's performance meets international standards but also indicate that the company's production processes, quality control, and technical capabilities are of a high standard.

By comparing the certification status and technical parameters of different products, builders and owners can more clearly distinguish between superior and inferior products. A waterproof breather membrane with multiple international certifications is a reliable and durable choice for achieving long-term protection for a building.

SFS non-woven PP breathable membrane for roof underlayment T150

日本語

日本語 Русский

Русский España

España عرب .

عرب .