Understanding Waterproof Breathable Membranes: Technology, Types, and Applications

2025-08-21

Staying dry and comfortable in challenging weather conditions is a priority for many, from outdoor enthusiasts to professionals working in the elements. The technology that makes this possible often hinges on a single, sophisticated component: the waterproof breathable membrane. This article delves deep into this advanced material, explaining how it works, the different types available, and how to choose the right one for your needs.

What is a Waterproof Breathable Membrane?

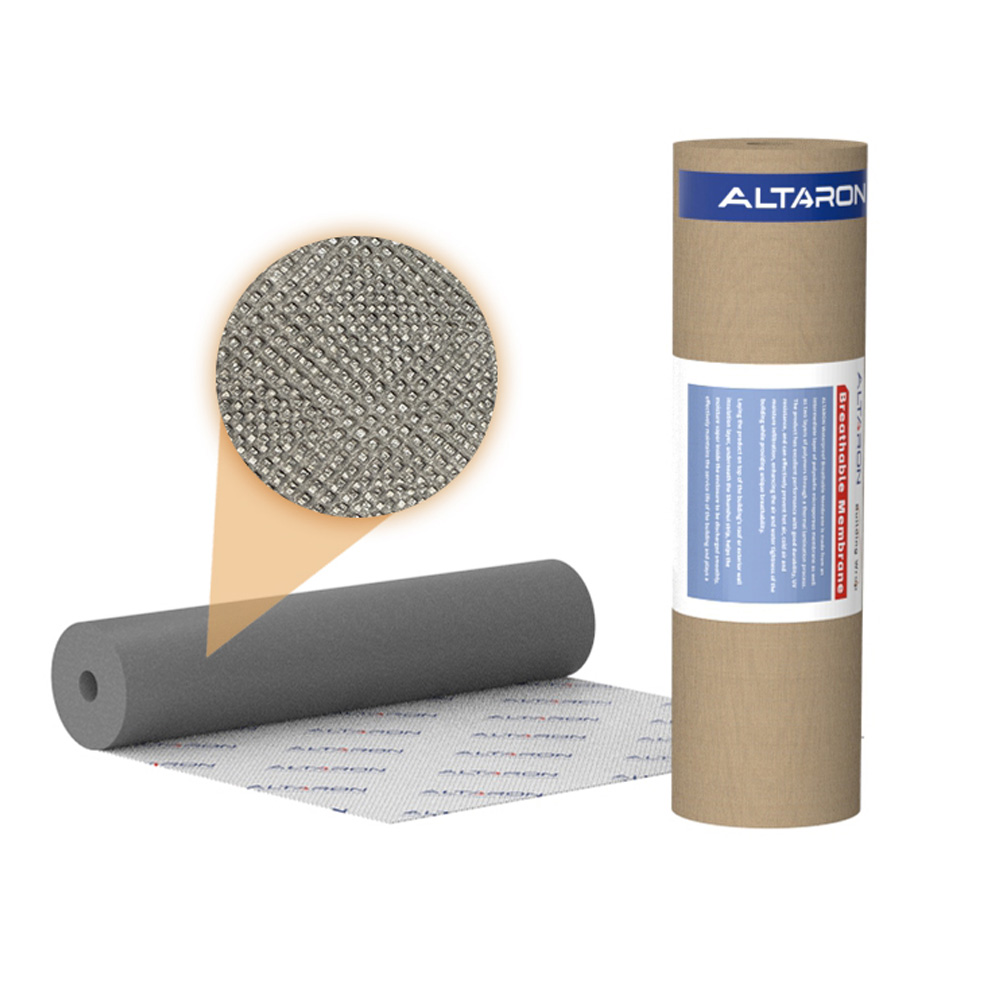

A waterproof breathable membrane is a thin, micro-porous or hydrophilic film laminated or coated onto textile fabrics. Its primary function is dualistic: to prevent liquid water from penetrating from the outside while allowing water vapor (sweat) to escape from the inside. This balance is crucial for maintaining comfort during physical activity.

How Does It Work?

The science behind these membranes is fascinating and is primarily achieved through two distinct mechanisms:

- Micro-porous: These membranes contain billions of microscopic pores per square centimeter. These pores are large enough to allow vapor molecules to pass through but small enough to block liquid water droplets.

- Hydrophilic (Solid): These are non-porous membranes that use a chemical process. They contain molecular chains that attract water vapor from the inside, transport it through the membrane via diffusion, and release it to the outside atmosphere.

Exploring the Different Types of Membranes

Not all membranes are created equal. Understanding the differences is key to selecting the right technology.

ePTFE Membranes: The High-Performance Standard

Expanded Polytetrafluoroethylene (ePTFE) is a micro-porous membrane renowned for its exceptional durability and high breathability.

- Pros: Unmatched breathability; highly durable; excellent chemical resistance.

- Cons: Can be compromised by oils and dirt without a protective layer; generally more expensive.

PU Membranes: The Versatile Contender

Polyurethane (PU) membranes can be either micro-porous or hydrophilic and are known for their versatility and cost-effectiveness.

- Pros: More affordable; resistant to oils and detergents; very flexible and soft.

- Cons: Generally offers lower breathability than high-end ePTFE; can be less durable over time.

TPU Membranes: The Durable Hybrid

Thermoplastic Polyurethane (TPU) membranes combine some benefits of both worlds, offering a robust and eco-friendlier alternative.

- Pros: Highly durable and abrasion-resistant; recyclable; good balance of performance and price.

- Cons: Can be heavier and less breathable than premium ePTFE options.

Membrane Comparison Table

| Type | Mechanism | Best For | Key Consideration |

| ePTFE | Micro-porous | High-intensity activities | Requires an oleophobic coating |

| PU | Micro-porous/Hydrophilic | Versatile, everyday use | Breathability can vary greatly |

| TPU | Often Hydrophilic | Durable and eco-conscious gear | Slightly heavier feel |

Key Performance Metrics: Waterproofness and Breathability

When evaluating a waterproof breathable membrane, two specs are paramount. Understanding the difference between a waterproof vs water resistant membrane is the first critical step for any consumer. While water-resistant fabrics can only repel light moisture, a true waterproof membrane is designed to withstand much higher pressure from water.

Measuring Waterproofness (Hydrostatic Head)

Waterproofness is measured in millimeters (mm) using a hydrostatic head test. A higher rating indicates better protection.

- 5,000mm: Suitable for light rain and dry snow.

- 10,000mm: Adequate for moderate rain and average snow sports.

- 20,000mm+: Designed for heavy rain, wet snow, and prolonged exposure.

Measuring Breathability (MVTR)

Breathability is measured as Moisture Vapor Transmission Rate (MVTR), indicating how many grams of vapor can pass through a square meter of fabric in 24 hours. A higher number is better.

- 5,000 g/m²/24hrs: Basic breathability for low-intensity activity.

- 10,000 - 15,000 g/m²/24hrs: Good for most hiking and skiing.

- 20,000+ g/m²/24hrs: High performance for intense exertion.

How to Choose the Right Membrane for Your Needs

Selecting the right membrane depends entirely on your intended use. This is where understanding the best waterproof breathable membrane for hiking versus one for running becomes crucial.

For High-Exertion Activities (Running, Ski Touring)

Prioritize high breathability ratings (e.g., 15,000+ MVTR). A lightweight, highly breathable ePTFE membrane is often the preferred choice.

For Static or Variable Conditions (Hiking, Hunting)

Look for a balance. A waterproof rating of 10,000-20,000mm and a breathability rating of 10,000-15,000 MVTR is a solid range. This is a key factor in determining the best waterproof breathable membrane for hiking.

For Extreme Weather and Durability (Alpine Climbing, Expedition Gear)

Focus on maximum waterproofness (20,000mm+) and robust construction (like reinforced TPU or high-end ePTFE), even if it adds slight weight.

Maintaining Your Gear for Longevity

A membrane's performance can degrade over time if not cared for properly. Learning how to care for and wash waterproof breathable clothing is essential to protect your investment.

- Always follow the manufacturer's washing instructions.

- Use technical detergents formulated for waterproof fabrics; avoid standard detergents and fabric softeners.

- Reapply a DWR (Durable Water Repellent) coating after washing to restore the outer fabric's bead-up effect.

- Tumble dry on low heat to reactivate the DWR treatment.

Common Myths and Misconceptions

Many believe that a membrane alone makes a garment waterproof and breathable. In reality, the entire garment construction matters. The concept of a 2 layer vs 3 layer waterproof breathable membrane construction is vital here. A 2-layer construction bonds the membrane to the outer fabric, often requiring a separate lining, while a 3-layer construction laminates the membrane, outer fabric, and a protective inner scrim into a single durable package. While 3-layer is typically more durable and lightweight, 2-layer can be more affordable and comfortable for casual use.

Conclusion

The waterproof breathable membrane is a marvel of modern textile engineering, enabling comfort and protection across a wide range of activities. By understanding the different types, key performance metrics, and proper care techniques, you can make an informed decision that ensures you stay dry and comfortable on your next adventure. Remember, the "best" membrane is the one that is perfectly suited to your specific needs and activity level.

Waterproof Breathable Membrane T80

日本語

日本語 Русский

Русский España

España عرب .

عرب .