Roof Waterproofing Guide: How to Choose an Air-Permeable Waterproof Membrane for Your Roof

2025-11-27

In modern construction, the roof system is the primary defense against water intrusion, but it must also manage internal moisture. The proper selection and installation of a Waterproof air permeable membrane for roof is therefore a critical engineering task for contractors and architects. These membranes perform two essential functions: preventing liquid water from entering the structure and allowing water vapor from within the building or structure to escape. Achieving this balance is key to preventing condensation, mold growth, and premature structural failure. Jiangsu Aotelong New Materials Co., Ltd. (Zhongning New Materials), located in the Yangtze River Delta, is a large enterprise specializing in certified, high-quality building enclosure materials, including high- and low-permeability membranes.

Membrane Functionality and Technical Metrics

Understanding vapor dynamics is central to selecting the right **Waterproof air permeable membrane for roof**.

Distinguishing Vapor barrier vs breathable membrane

The core difference between a **Vapor barrier vs breathable membrane** lies in their vapor transmission rate (VTR), often expressed as a Perm rating. A vapor barrier (typically less than 1.0 Perm) is designed to drastically restrict the flow of water vapor, typically placed on the warm side of the insulation in cold climates. Conversely, a breathable membrane (often 10 Perm or higher) is designed to allow significant vapor passage. Selecting the wrong material can lead to trapping moisture, which is why a **High permeability roof membrane** is usually preferred for exterior sheathing application.

Comparison: Vapor Barrier vs. Breathable Membrane (Primary Function and Perm Rating):

| Membrane Type | Vapor Transmission Rate (VTR) | Primary Function in Assembly |

|---|---|---|

| Vapor Barrier | Low (Typically < 1.0 Perm) | Restrict vapor movement |

| Breathable Membrane | High (Typically > 10 Perm) | Allow vapor to escape (promote drying) |

The role of High permeability roof membrane in moisture control

A High permeability roof membrane is essential for managing incidental moisture. During construction, sheathing and framing materials can absorb moisture from rain or humidity. After the roof is enclosed, a high Perm membrane allows this trapped moisture to diffuse outward and escape, promoting the drying of the structure. This passive drying mechanism significantly reduces the risk of long-term moisture accumulation, which can lead to rot and fastener corrosion within the roof assembly.

UV resistant roofing underlayment for extended exposure

In commercial construction, delays are common, meaning the roofing underlayment may be exposed to solar radiation for weeks or months before the final roofing material is applied. Standard membranes can quickly degrade when exposed to sunlight. Specifying a **UV resistant roofing underlayment** is a crucial quality assurance step, as it prevents embrittlement, tearing, and reduction of water resistance before the permanent covering is installed. Our products are engineered with robust UV stabilization to maintain integrity during extended exposure.

Installation and System Integration

The membrane's effectiveness is only as good as its installation and integration into the whole building envelope.

Best practices for Air permeable roof membrane installation

Correct Air permeable roof membrane installation requires meticulous attention to lapping and sealing. The membrane must be installed shingle-style, with all horizontal laps overlapping the layer below to shed water effectively. Seams must be sealed with compatible tape (often recommended by the manufacturer) to ensure continuous waterproofing. Detailing around penetrations—such as vent pipes, skylights, and chimneys—using specialized flashing and adhesive sealants is essential to maintain the integrity of the **Waterproof air permeable membrane for roof**.

Integrating the Building envelope breathable membrane system

The **Building envelope breathable membrane** is not an isolated product; it must work seamlessly with the wall system, flashing, and window/door interfaces. The membrane acts as the secondary weather barrier, protecting the sheathing. Architects and contractors must ensure continuous connection between the wall and roof membranes to prevent water from migrating behind the system. Our expertise extends to providing both low-permeability and **High permeability roof membrane** materials that integrate flawlessly with other components in the **Building envelope breathable membrane**.

Quality Assurance and Certification

Third-party certification validates the product claims and ensures reliability for B2B purchasers.

Verifying performance through certification

Procurement must prioritize **Waterproof air permeable membrane for roof** products that have passed recognized third-party certifications, such as the UK BBA or US ICC-ES factory inspections, as our company has achieved. These certifications verify performance criteria including water resistance, tear strength, VTR, and the stability of the **UV resistant roofing underlayment**. This provides independent assurance that the product will perform reliably under specified service conditions.

Customized Solutions from the Manufacturer

As a large, integrated manufacturer, Jiangsu Aotelong New Materials controls the production from the PP spunbond non-woven fabric base to the final composite membrane. This capability allows us to offer customized **High permeability roof membrane** solutions, adapting the Perm rating and physical strength to meet specific project demands, such. Our certified manufacturing process ensures that every product contributes reliably to the **Building envelope breathable membrane** system.

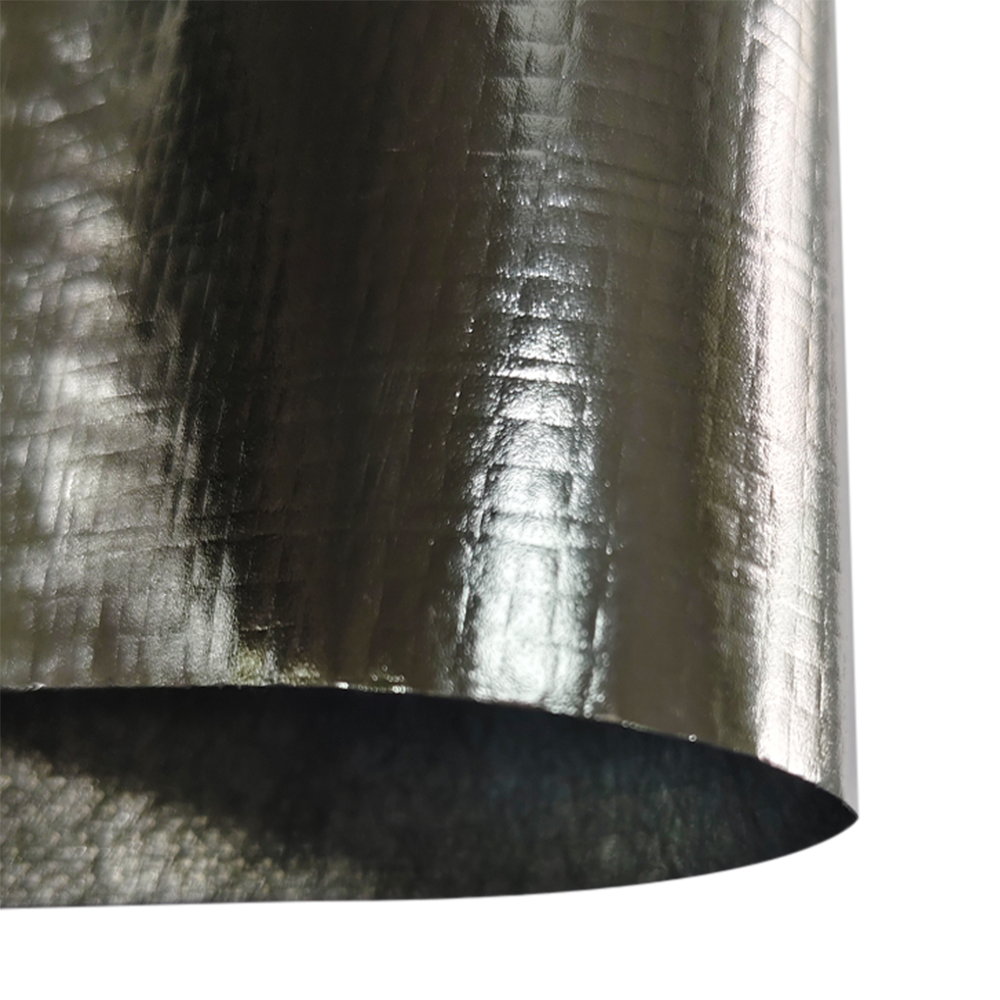

Black Multilayer Composite Reflective Film AWN140

Conclusion

The successful execution of a modern roofing system depends on making informed decisions regarding the **Waterproof air permeable membrane for roof**. Key steps include understanding the critical difference between a **Vapor barrier vs breathable membrane**, specifying products with documented **UV resistant roofing underlayment** properties, and ensuring rigorous **Air permeable roof membrane installation**. Jiangsu Aotelong New Materials is committed to supplying certified, high-performance materials that provide the durability and moisture management required for a superior **Building envelope breathable membrane**.

Frequently Asked Questions (FAQ)

- What is the typical Perm rating for a **High permeability roof membrane**? A **High permeability roof membrane** is generally categorized as having a Perm rating greater than 10 US Perms, classifying it as vapor permeable. This high rating is essential for maximizing the drying potential of the roof assembly.

- Is a primer needed before **Air permeable roof membrane installation**? Generally, no primer is needed for the main membrane. However, specialized primers or sealants are often required for tape application, sealing penetrations, and ensuring adhesion to challenging substrates like concrete or masonry, which is vital for proper **Air permeable roof membrane installation**.

- How does the lifespan of a **Waterproof air permeable membrane for roof** compare to the final roof covering? The membrane is designed to be a long-term component of the **Building envelope breathable membrane** system, often lasting 50 years or more. However, its exposure rating (time it can be left uncovered) is typically limited to 6 or 12 months, emphasizing the importance of **UV resistant roofing underlayment** properties.

- What is the minimum required overlap for the seams of a **Waterproof air permeable membrane for roof**? Industry best practice and manufacturer specifications typically require a minimum horizontal overlap of 6 inches (150 mm) and a vertical overlap of 12 inches (300 mm) to ensure effective water shedding and maintain the integrity of the secondary barrier.

- What risk does not using a **UV resistant roofing underlayment** pose during construction? Non-UV-stabilized membranes can become brittle, chalky, and lose tensile strength rapidly—sometimes within a few weeks—when exposed to sunlight. This degradation makes the material prone to tearing during subsequent trades (e.g., roofers), compromising the water barrier before the final roof surface is applied.

日本語

日本語 Русский

Русский España

España عرب .

عرب .