The Future of Outdoor Gear: How Waterproof Breathable Membranes Are Revolutionizing Performance

2025-07-04

Understanding Waterproof Breathable Membranes

Modern outdoor enthusiasts demand gear that keeps them dry while allowing sweat to escape. This is where waterproof breathable membranes come into play. These advanced materials create a barrier against external moisture while permitting internal vapor to pass through, making them indispensable for high-performance apparel.

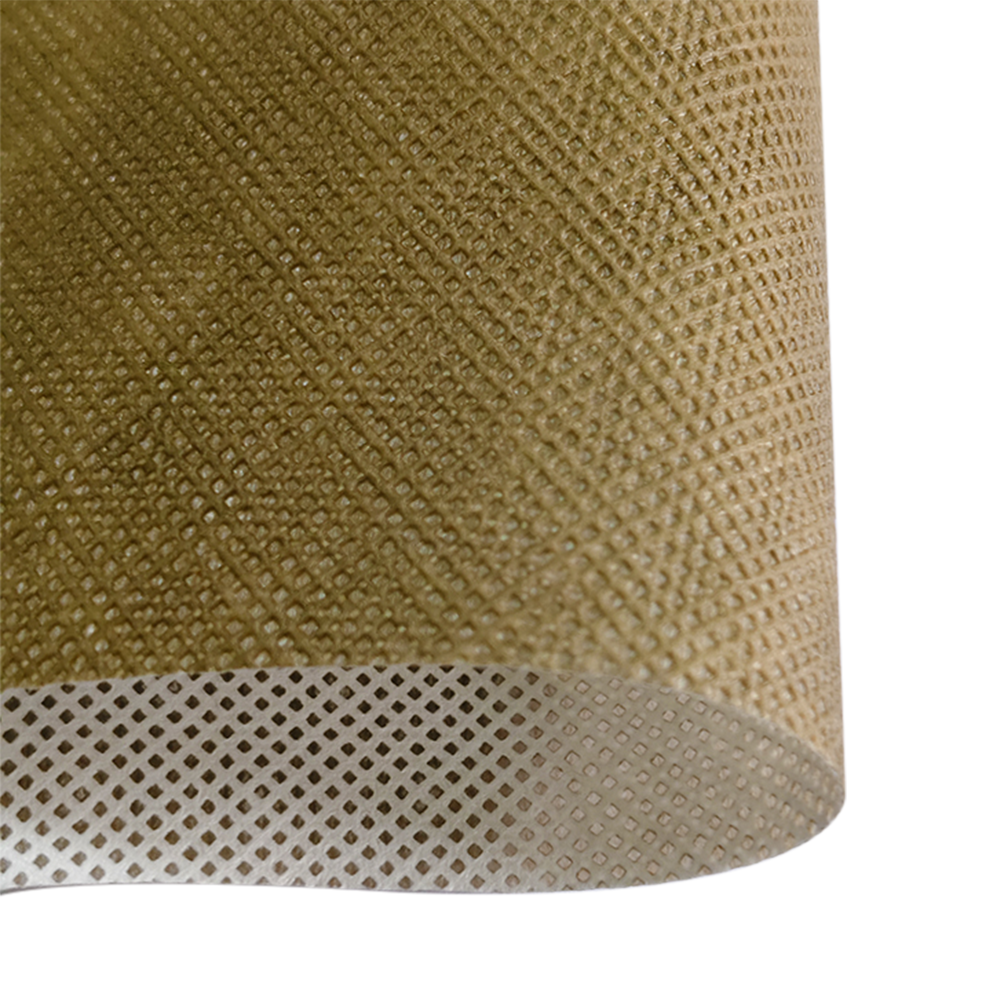

Waterproof Breathable Membrane T180

1.1 The Science Behind the Technology

These membranes work through microscopic pores that are smaller than water droplets but large enough to allow water vapor molecules to escape. The result is a fabric that maintains dryness in two directions. Unlike traditional waterproof materials that trap sweat, breathable waterproof fabrics for hiking regulate temperature and comfort during intense activity.

1.2 Key Performance Metrics

When evaluating these membranes, three factors matter most:

| Metric | Ideal Range | Measurement |

|---|---|---|

| Water Resistance | 10,000mm+ | Hydrostatic head test |

| Breathability | 10,000g/m²/24hr+ | Moisture vapor transmission rate |

| Durability | 50+ washes | Maintained performance after laundering |

Choosing the Right Membrane for Your Needs

Not all waterproof breathable membranes perform equally across different activities. Understanding their variations ensures optimal selection for specific use cases.

2.1 Comparing Membrane Types

The market offers three primary technologies, each with distinct advantages:

| Type | Best For | Limitations |

|---|---|---|

| Microporous | lightweight waterproof membranes for running | Can clog over time |

| Hydrophilic | Extreme cold conditions | Slower vapor transfer |

| Bi-component | All-weather versatility | Higher cost |

2.2 Activity-Specific Recommendations

For best waterproof breathable materials for skiing, prioritize membranes with high breathability ratings (15,000g+) and reinforced durability. Alpine conditions demand rapid moisture transfer to prevent condensation buildup during temperature fluctuations.

Maintenance and Longevity Tips

Proper care dramatically extends the functional lifespan of waterproof breathable membranes. Neglecting maintenance can reduce performance by up to 70% within a year of regular use.

3.1 Washing Protocols

Contrary to intuition, regular washing actually preserves membrane function. Dirt and oils clog microscopic pores, impairing both waterproofing and breathability. For durable waterproof breathable fabrics, follow these guidelines:

| Step | Recommendation | Frequency |

|---|---|---|

| Pre-treatment | Spot clean heavy stains | Before each wash |

| Detergent | Technical fabric cleaners only | Every wash |

| Drying | Tumble dry low heat | After every wash |

3.2 Rejuvenating Waterproofing

Even with proper care, all membranes eventually need re-treatment. The eco-friendly waterproof breathable technologies now available use plant-based DWR (durable water repellent) coatings that restore beading effect without harmful chemicals.

Innovations Shaping the Future

The next generation of waterproof breathable membranes addresses current limitations while introducing groundbreaking capabilities.

4.1 Self-Cleaning Nanotechnology

Emerging membranes incorporate photocatalytic nanoparticles that break down organic contaminants when exposed to light. This innovation could eliminate the primary cause of membrane degradation - pore clogging from body oils and environmental grime.

4.2 Adaptive Porosity Systems

Experimental fabrics now adjust pore size dynamically in response to activity level and environmental conditions. This represents a significant leap from static membranes, potentially creating the ultimate lightweight waterproof membranes for running that optimize performance in real-time.

Environmental Considerations

As sustainability becomes paramount, manufacturers are reengineering waterproof breathable membranes to reduce ecological impact without compromising performance.

5.1 Biodegradable Alternatives

New plant-based polymers demonstrate comparable performance to traditional petroleum-derived membranes. These eco-friendly waterproof breathable technologies decompose significantly faster at end-of-life while maintaining essential characteristics during use.

5.2 Recycling Challenges and Solutions

The complex composition of membranes historically made recycling impractical. However, novel separation techniques now allow recovery of up to 85% of materials, transforming the sustainability profile of durable waterproof breathable fabrics.

日本語

日本語 Русский

Русский España

España عرب .

عرب .