How to Balance Vapor Permeability and Airtightness When Selecting an air and water barrier membrane for High-Performance Envelopes?

2026-01-15

In the field of building science, the integrity of the building envelope is paramount to both energy efficiency and structural longevity. Engineers must address the paradoxical challenge of making a facade airtight to prevent energy loss while ensuring it remains vapor-permeable to allow moisture to escape. Selecting the correct air and water barrier membrane is the definitive solution to this challenge. Jiangsu Aotelong New Materials Co., Ltd. (Zhongning New Materials Jiangsu Co., Ltd.), based in the new materials hub of Yangzhou, is a leading manufacturer specializing in building enclosure solutions. Our technical range, including high permeability waterproof breathable membrane and vapor barrier systems, has successfully passed rigorous US ICC-ES and UK BBA factory inspections, meeting CE and BBA certification standards for global commercial applications.

The Engineering Conflict: Airtightness vs. Vapor Diffusion

Airtightness is a measurable metric of how well a building prevents uncontrolled air leakage, which can account for up to 40% of a building's heating and cooling energy use. Conversely, vapor permeability refers to the membrane's ability to allow water vapor molecules to pass through via diffusion. For high-performance envelopes, the commercial building envelope weather barrier must act as a total air block while maintaining a specific "Perm" rating to prevent interstitial condensation. According to the 2024-2025 energy conservation standards released by the International Code Council (ICC), high-performance enclosures now require an air leakage rate of less than 0.02 L/(s·m²) under a pressure of 75 Pa to meet Net Zero targets.

Source: International Code Council: 2024 International Energy Conservation Code (IECC)

Comparison: Vapor Permeable vs. Non-Permeable Membranes

The choice between these two types depends heavily on the climate zone and the assembly's drying potential. Vapor permeable membranes are designed to facilitate outward drying, whereas non-permeable membranes (vapor barriers) are intended to stop vapor drive entirely.

| Feature | Vapor Permeable Membrane | Non-Permeable Vapor Barrier |

| Primary Function | Allows moisture vapor to escape out of the wall. | Blocks vapor from entering the wall assembly. |

| Airtightness | Excellent (if installed correctly). | Excellent (if joints are sealed). |

| Recommended Use | Cold/Mixed climates; exterior side of insulation. | Warm/Humid climates; interior side of insulation. |

Technical Specifications for High-Performance Envelopes

When engineers evaluate vapor permeable air barrier manufacturers, they look for the "Perm" rating. A high permeability waterproof breathable membrane typically offers a Perm rating higher than 10, which ensures that even if small amounts of water penetrate the cladding, the assembly can dry out before mold or rot occurs. Furthermore, for modern architectural designs involving rainscreens, a UV resistant house wrap for open joint cladding is necessary. These membranes must withstand high levels of solar radiation without losing their mechanical or airtight properties over the service life of the building.

Durability and Installation Integrity

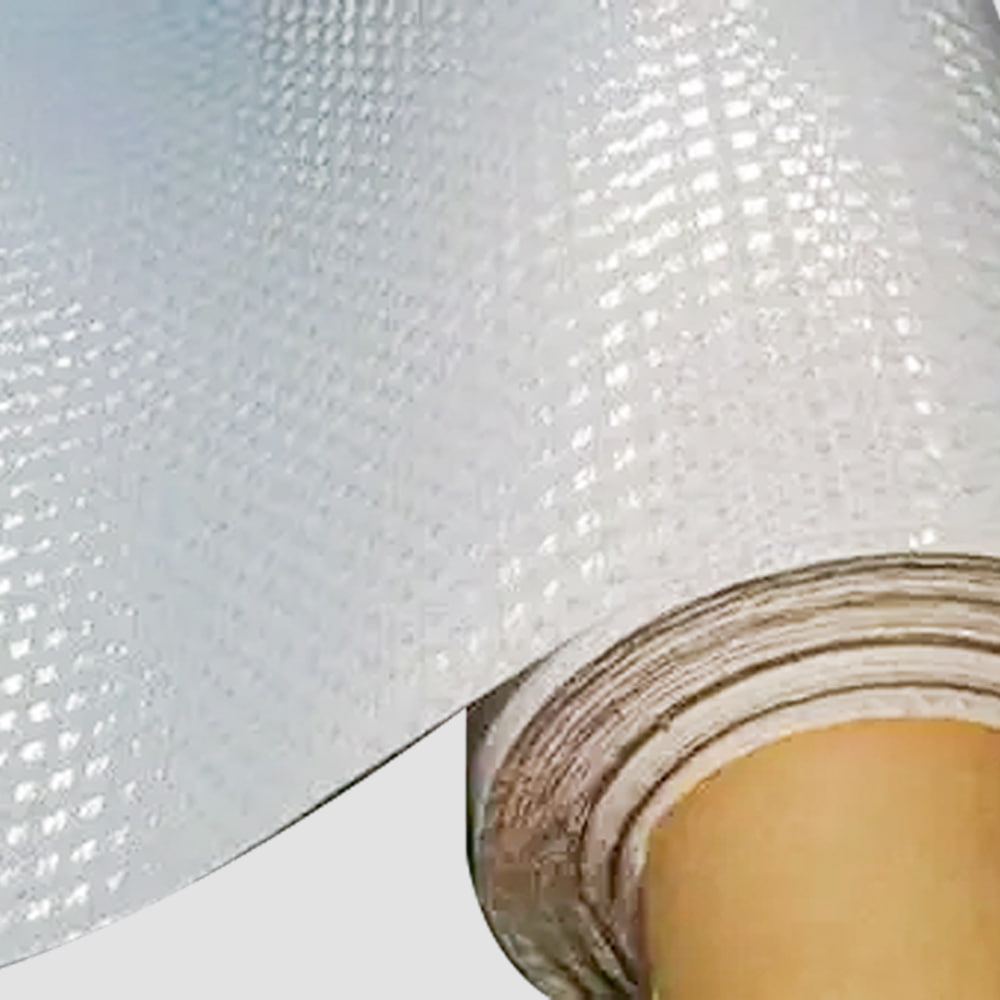

Material performance is only half the battle; installation method plays a critical role in maintaining the air barrier's continuity. A self-adhered vapor permeable membrane for facades reduces the risk of air leakage at fastener penetrations, which is a common failure point in mechanically attached wraps. Recent technical bulletins from the Air Barrier Association of America (ABAA) suggest that self-adhered systems can improve overall airtightness by up to 25% compared to traditional stapled wraps.

Source: Air Barrier Association of America: Technical Research and Air Leakage Statistics 2024

The Role of Aotelong in Global Building Standards

At Jiangsu Aotelong New Materials, we integrate material innovation with full-scale production. Our products, including PP spunbond non-woven fabrics and SMS/SMMMS composite materials, serve as the foundation for our high-end air and water barrier membrane solutions. By maintaining certifications like CE and BBA, we ensure that our high permeability waterproof breathable membrane meets the rigorous requirements of European and British building codes. Our 30,000-square-meter facility produces materials that are not only sound-absorbing and flame-retardant but also technically optimized for thermal insulation and moisture control.

Comparison: Mechanical Attachment vs. Self-Adhered Systems

Mechanical attachment is often faster for initial coverage, but self-adhered systems provide a superior airtight seal, especially around complex window and door transitions.

| Criteria | Mechanically Attached Wrap | Self-Adhered Membrane |

| Fastener Penetrations | Many; risk of small air leaks. | Zero; creates a continuous bond. |

| Wind Loading Resistance | Moderate; can tear at staples. | High; fully bonded to the substrate. |

| Vapor Control | High Permeability options available. | High Permeability options available. |

Conclusion: The Future of Breathable Building Envelopes

Balancing vapor permeability and airtightness is a delicate engineering act. By specifying an air and water barrier membrane with a high Perm rating and ensuring airtight joints—ideally through a self-adhered vapor permeable membrane for facades—professionals can protect the structural integrity of the building. Jiangsu Aotelong New Materials Co., Ltd. remains dedicated to supplying the commercial building envelope weather barrier products required for the sustainable, energy-efficient cities of tomorrow. Our ICC-ES and BBA-certified materials provide the technical reliability needed for the most challenging architectural environments.

Frequently Asked Questions (FAQ)

- What is the ideal Perm rating for a high permeability waterproof breathable membrane? Most engineers look for a rating between 10 and 50 Perms, depending on the climate and the specific cladding type used.

- Can an air and water barrier membrane be left exposed to the sun? Only if it is a UV resistant house wrap for open joint cladding. Standard membranes may degrade within 30 to 90 days of UV exposure.

- Why are vapor permeable air barrier manufacturers focusing on self-adhered technology? Because it eliminates the "bellows effect" and air bypass that occurs when traditional wraps flap under wind pressure.

- Is Aotelong's membrane compatible with European building codes? Yes, our products have passed European CE certification and British BBA certification, making them suitable for EU and UK projects.

- Does a commercial building envelope weather barrier affect thermal insulation? Yes, by preventing air leakage, it ensures that the R-value of the insulation is not compromised by cold air infiltration.

日本語

日本語 Русский

Русский España

España عرب .

عرب .