Key Technical Features

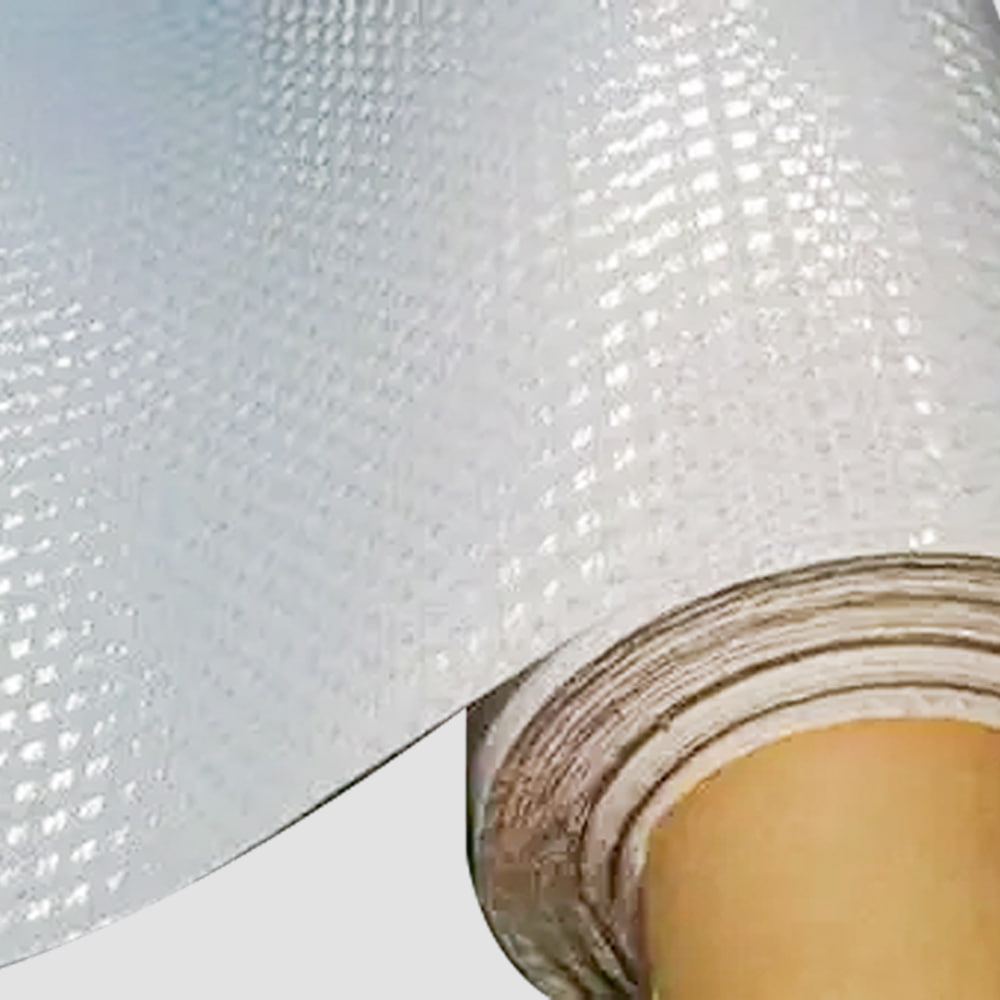

- Composite construction: polyethylene film + woven mesh reinforcement to provide combined vapour control and tear resistance.

- Controlled vapour permeance: engineered to limit moisture movement in conditioned building assemblies.

- Mechanical reinforcement: woven layer improves tensile strength, dimensional stability and fastener retention during installation.

- Compatibility with common tapes, sealants and mechanical fixings used in construction detailing.

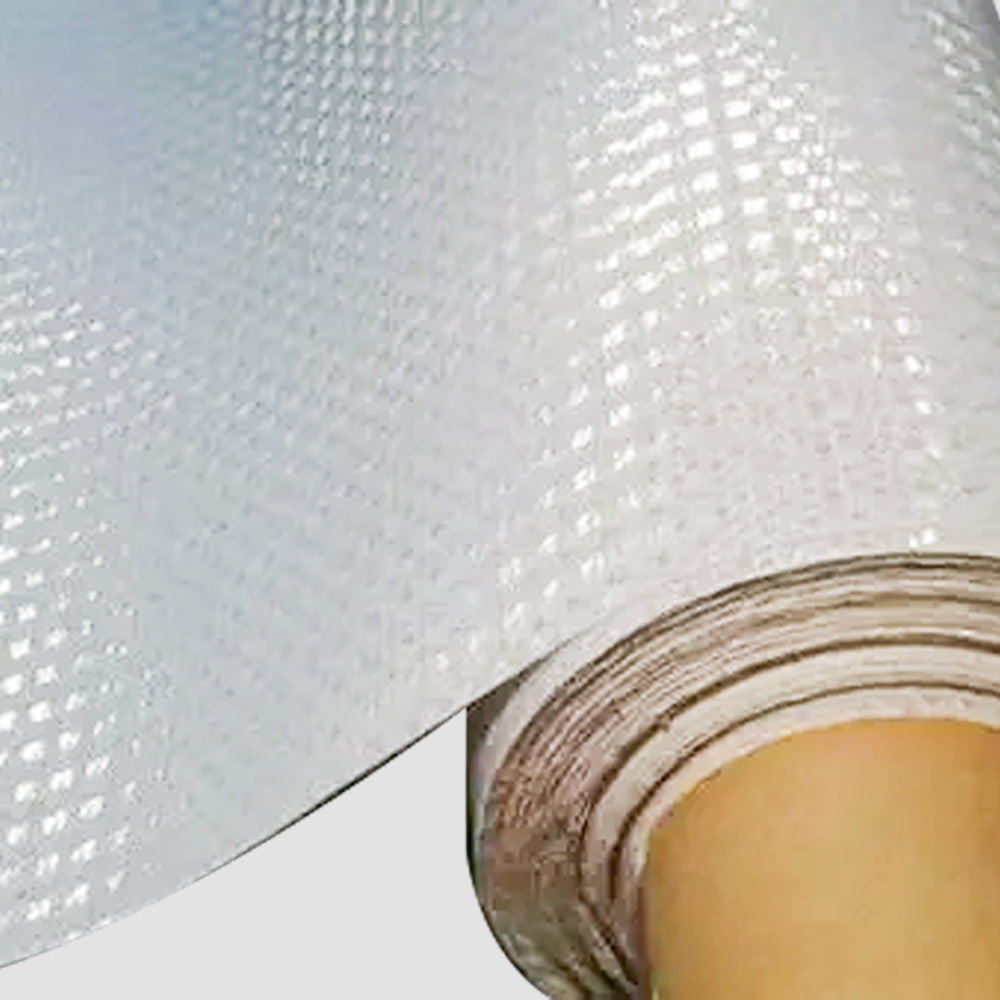

- Roll format for rapid application on horizontal and vertical surfaces.

Primary Applications

Roof assemblies

Used as a polyethylene vapor control layer for roofing beneath insulation or within roof cavities to reduce inward and outward vapour migration. Suitable for retrofit and new-build projects requiring a reinforced vapour layer.

Wall assemblies

Applied on the warm side of insulation in cold climates or positioned per hygrothermal design for balanced assemblies. The mesh reinforcement aids in maintaining continuity across wall joists and sheathing interfaces.

Other uses

Applicable as an internal vapour control layer for suspended ceilings, floor systems and selective industrial enclosures where a reinforced polyethylene sheet is specified.

Installation Guidance

General recommendations

Install with the polyethylene surface oriented as specified in the project hygrothermal design. Overlap adjacent sheets according to project requirements (commonly 50–150 mm). Use approved sealing tapes and sealants at laps, penetrations and terminations to maintain a continuous vapor control layer. Mechanically fasten per substrate type and avoid point stresses that may compromise the woven mesh.

Roof application notes

- Lay rolls parallel to roof eave-to-ridge direction on pitched roofs for efficient seam layout.

- Confirm interaction with ventilation or drainage layers required by local codes.

Wall application notes

- Position on the warm-in-winter side of insulation where required by climate-specific design.

- Integrate with air barrier systems where applicable to provide combined air and vapour control.

Technical Specifications (Typical ranges)

Typical values are shown for selection. Project-specific test reports and dimensional customization are available upon request.

| Construction | Polyethylene film laminated to woven polyester/PP mesh | Composite for vapour control and reinforcement |

| Nominal thickness | 0.08 mm – 0.30 mm | Dependent on film gauge and mesh weight |

| Basis weight | 40 – 180 g/m² | Specify GSM when ordering |

| Water vapour transmission (WVTR) | < 0.5 g/m²·24h (typical) — low permeance options available | Measured per ASTM or ISO on request |

| Tensile strength (MD / CD) | ≥ 150 N / 120 N (typical) | Values vary with mesh type |

| Tear resistance | ≥ 80 N (typical) | Mesh reinforcement increases tear performance |

| Puncture resistance | Improved compared to single-layer PE films | Project-specific testing recommended |

| Operating temperature range | -40 °C to +100 °C (typical) | Short-term excursions may be higher |

| Roll widths | 0.6 m, 1.0 m, 1.2 m, 1.5 m (custom widths available) | Standard construction widths |

| Roll lengths | 25 m, 50 m, 100 m | Available per order |

| Packaging | Core-wound rolls, protective wrapping, palletised | Export packaging options available |

| Certifications | Factory inspection and test documentation available | See manufacturer support for ICC-ES, BBA, CE and national test reports |

Performance Considerations

Selection of film gauge and mesh density should align with the project's target vapour permeance, mechanical handling requirements and local code provisions. For cold climate applications, evaluate the placement of the vapor control layer relative to insulation using hygrothermal analysis to avoid interstitial condensation risk. When combined with reflective layers or insulation boards, confirm the overall assembly performance through simulation or empirical testing.

Frequently Asked Questions (FAQ)

Q1: Can the mesh-reinforced polyethylene layer serve as a continuous vapor barrier for both roof and wall systems?

A1: When installed with continuous sealed laps, properly detailed penetrations and compatible termination details, the product will function as a vapor control layer for building envelope assemblies in roof and wall systems. Project-specific placement (warm side vs. cold side) should be determined by hygrothermal analysis and applicable code requirements. Jiangsu Aotelong New Materials Co., Ltd. provides installation guidance and test data to support specification and procurement.

Q2: How should I specify the product to ensure adequate mechanical performance during installation?

A2: Specify the film gauge, mesh yarn type and mesh density according to expected handling, fastening methods and exposure during installation. For mechanically fastened applications, request tensile and tear resistance data from the manufacturer. Jiangsu Aotelong New Materials Co., Ltd., as a manufacturer integrating R&D, production and sales, can supply material data sheets and factory inspection documentation (including ICC-ES and UK BBA factory inspections where applicable) to verify performance for tender and submittal packages.

Q3: What manufacturer certifications and test reports are available?

A3: Manufacturer documentation is available to support project procurement. Jiangsu Aotelong New Materials Co., Ltd. operates from Yangzhou City, Jiangsu Province, and produces a range of building enclosure materials including vapor barrier membranes and reflective insulation membranes. The company has completed factory inspections such as US ICC-ES and UK BBA; selected product lines have test reports from the National Building Materials Testing Center and CE/BBA certification where applicable. Request specific certificates and third-party test reports for project submittals.

Ordering Information

Provide project parameters (required coverage area, target vapour permeance, expected climate conditions and applicable codes) when requesting a quotation. Custom thickness, mesh specification and roll dimensions are available. Lead time and pricing depend on order quantity and certification needs.

日本語

日本語 Русский

Русский España

España عرب .

عرب .