Key Points and Common Misunderstandings About Waterproof and Breathable Membrane Installation

2025-10-24

Proper installation of Waterproof Air Permeable Membrane is crucial for achieving optimal performance in building envelopes and other applications. While these advanced materials offer exceptional protection against water ingress while allowing vapor transmission, their effectiveness heavily depends on correct installation practices. This comprehensive guide explores the essential installation techniques and addresses widespread misconceptions that can compromise membrane performance, leading to moisture issues, reduced energy efficiency, and potential structural damage over time.

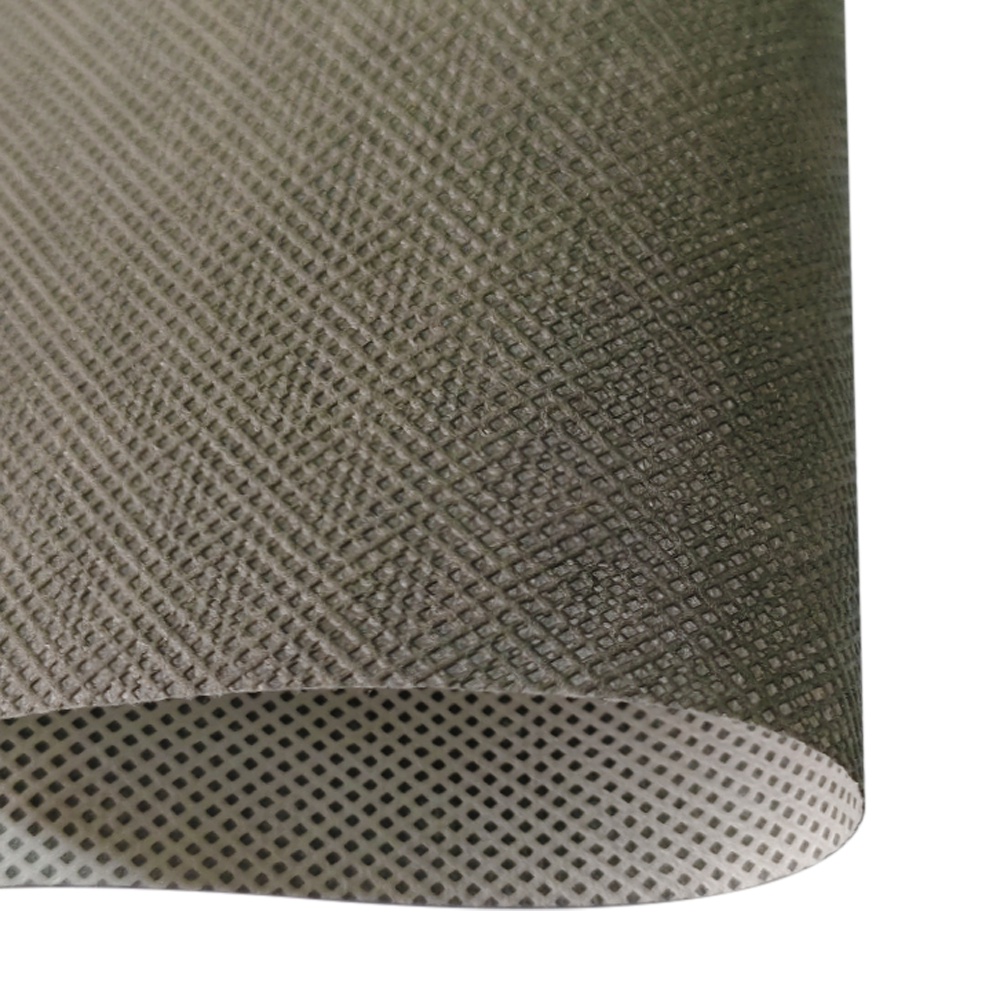

Waterproof Breathable Membrane T120

Fundamental Principles of Waterproof Breathable Membrane Functionality

Understanding how waterproof breathable membranes work is essential before addressing installation specifics. These membranes operate on the principle of selective permeability, allowing water vapor molecules to pass through while blocking liquid water. The science behind this involves either microporous structures with billions of tiny pores or non-porous monolithic films that use molecular diffusion. Proper installation ensures this sophisticated technology performs as intended, creating a balanced building envelope that manages moisture effectively throughout seasonal changes and varying climate conditions.

- Vapor Diffusion Management: Allows internally generated moisture to escape, preventing condensation within wall and roof assemblies.

- Liquid Water Resistance: Provides a reliable barrier against rain, snow, and ground moisture penetration.

- Air Flow Regulation: Some membranes serve as air barriers, reducing energy loss and improving indoor comfort.

- Thermal Performance Protection: By keeping insulation dry, membranes maintain consistent R-values and energy efficiency.

Critical Pre-Installation Preparation Steps

Successful installation begins long before the membrane is unrolled. Proper preparation ensures the substrate is ready to receive the membrane and that all necessary components are available. This phase is often overlooked but is fundamental to achieving a durable, high-performing installation that will protect the structure for decades. A thorough pre-installation checklist can prevent common issues that arise from inadequate preparation and substrate deficiencies.

- Substrate Inspection and Preparation: Check for structural integrity, cleanliness, and dryness before beginning installation.

- Weather Condition Assessment: Install within recommended temperature ranges and avoid installation during precipitation or high winds.

- Material Verification: Confirm you have the correct membrane type for your specific application and climate zone.

- Tool and Fastener Readiness: Ensure all necessary installation tools, fasteners, and sealing tapes are readily available.

Essential Substrate Requirements for Optimal Performance

The substrate must meet specific criteria to ensure the waterproof breathable membrane installation performs as designed. Different substrate materials require particular attention to detail during preparation to avoid future performance issues.

- Wood Sheathing: Must be dry, properly spaced (typically 1/8 inch between panels), and free from protruding fasteners.

- Concrete and Masonry: Should be cured completely, with surface irregularities addressed to prevent membrane damage.

- Metal Substrates: Require corrosion protection and appropriate fastening systems compatible with both materials.

- Insulation Surfaces: Must be even and continuous, with any gaps filled to create a uniform supporting surface.

Correct Installation Techniques for Maximum Effectiveness

Proper installation methodology varies depending on the specific application, but certain fundamental techniques apply across most scenarios. Understanding these core principles is essential for anyone involved in how to install waterproof breathable membrane correctly. The goal is to create continuous, uninterrupted protection that manages water and vapor effectively while withstanding environmental stresses throughout the building's lifespan.

- Directional Installation: Always follow manufacturer guidelines regarding which side faces outward and proper orientation.

- Lap and Seam Techniques: Implement correct overlapping dimensions (typically 4-6 inches for vertical seams, 6 inches for horizontal) with proper sealing.

- Fastening Patterns: Use recommended fastening spacing and types to secure the membrane without compromising its integrity.

- Integration with Other Components: Ensure proper detailing around penetrations, corners, and transitions to other building elements.

Step-by-Step Wall Installation Procedure

Wall applications represent one of the most common uses for waterproof breathable membranes, and following a systematic approach ensures comprehensive protection against weather elements while maintaining breathability.

- Starting Point Selection: Begin at the bottom of walls and work upward, allowing upper layers to shed water over lower sections.

- Horizontal Seam Management: Create shingle-style laps with upper sheets overlapping lower sheets by the recommended distance.

- Corner Detailing: Use appropriate folding or cutting techniques at inside and outside corners to maintain continuity.

- Opening Protection: Install membrane around windows and doors with integrated flashing or specialized tapes for water management.

| Installation Element | Correct Technique | Common Error |

| Seam Overlap | 4-6 inch minimum with proper sealing | Insufficient overlap or unsealed seams |

| Fastener Placement | Even spacing per manufacturer specs | Over-fastening or uneven distribution |

| Penetration Sealing | Fully integrated with flashing and sealants | Incomplete sealing around penetrations |

| Bottom Edge Termination | Properly integrated with foundation flashing | Direct termination without appropriate detailing |

Common Installation Misunderstandings and Errors

Many installation problems stem from misconceptions about how waterproof breathable membranes function and interact with other building components. Addressing these common errors proactively can prevent costly callbacks and building performance issues. Even experienced installers can fall victim to these misunderstandings if they haven't received updated training on modern membrane technology and building science principles.

- "Tighter is Always Better" Misconception: Excessive tension can cause tearing and compromise long-term performance.

- Improper Fastener Usage: Using incorrect fasteners or over-driving them creates potential leak paths.

- Inadequate Seam Treatment: Assuming seams will self-seal or neglecting proper taping procedures.

- Wrong-Side Installation: Failing to identify and install the correct side facing outward.

Debunking the "Double Barrier" Myth

One particularly persistent misunderstanding involves installing multiple layers of waterproof breathable membrane for "extra protection." This approach typically creates more problems than it solves and violates fundamental building science principles.

- Vapor Trap Creation: Multiple membranes can trap moisture between layers, leading to condensation and material degradation.

- Reduced Drying Potential: Additional layers impede the drying capability of the assembly, potentially prolonging moisture issues.

- Warranty Implications: Most manufacturers void warranties if their products are installed over or under competing membranes.

- Proper Alternative: Use a single, correctly installed high-quality membrane rather than multiple inferior layers.

| Misunderstanding | Reality | Proper Approach |

| More layers = better protection | Can create vapor traps and reduce drying | Single, properly installed quality membrane |

| Any tape will work for seams | Compatibility is crucial for long-term adhesion | Use manufacturer-recommended tapes only |

| Wrinkles don't matter | Can channel water and stress the material | Install smooth with minimal wrinkles |

| All membranes work the same | Performance varies significantly by type | Select membrane specific to application needs |

Special Considerations for Different Climate Zones

The performance requirements for waterproof breathable membranes vary significantly based on climate conditions. What works perfectly in a hot, humid climate may be inappropriate for a cold climate, and vice versa. Understanding these regional differences is crucial for specifying and installing the right membrane for your specific location and avoiding performance problems related to climate incompatibility.

- Cold Climate Considerations: Focus on interior vapor drive management and freeze-thaw cycle resistance.

- Hot-Humid Climate Requirements: Prioritize high vapor permeability and UV resistance for exterior applications.

- Mixed Climate Challenges: Require membranes that perform well under varying seasonal conditions.

- Marine Environment Demands: Need enhanced resistance to salt spray and high wind-driven rain.

Installation Variations for Roof vs. Wall Applications

While the fundamental principles remain consistent, specific installation techniques differ between vertical wall applications and sloped roof scenarios. Understanding these distinctions ensures the waterproof breathable membrane performs optimally in each context.

- Roof-Specific Requirements: Typically require higher puncture resistance and different fastening patterns.

- Wall-Specific Considerations: Often need higher vapor permeability and different integration with cladding systems.

- Detail Variations: Flashing, edge termination, and penetration details differ significantly between applications.

- Drainage Plane Management: Roof membranes often function as part of a drainage system, while walls may not.

Quality Assurance and Performance Verification

Verifying proper installation is as important as the installation process itself. Implementing a systematic quality assurance process helps identify and correct issues before they become hidden problems that compromise building performance. This final phase ensures that the waterproof breathable membrane installation meets both manufacturer specifications and building code requirements for long-term reliability.

- Visual Inspection Protocols: Methodically examine all seams, fasteners, and integration points.

- Documentation Requirements: Maintain thorough records of installation conditions and any deviations from standard practice.

- Performance Testing Options: Consider specialized testing for critical applications or complex building designs.

- Warranty Registration: Complete all necessary documentation to activate manufacturer warranties.

FAQ

Can waterproof breathable membrane be installed in cold weather?

Yes, but with important precautions. Most waterproof breathable membranes can be installed in temperatures as low as 20°F (-6°C), but flexibility and handling characteristics change in cold conditions. Membranes should be stored in a warm environment until immediately before installation and handled carefully to avoid cracking. Sealing tape adhesion may be compromised in cold temperatures, so following manufacturer recommendations for minimum application temperatures is crucial. Some manufacturers offer cold-weather specific tapes or membranes designed for installation in lower temperature ranges.

How long does waterproof breathable membrane last after installation?

The service life of properly installed waterproof breathable membrane typically matches the design life of the building component it protects. High-quality membranes from reputable manufacturers are designed to last 50 years or more when installed correctly and protected from UV exposure. The actual lifespan depends on membrane material, installation quality, environmental conditions, and maintenance. Products from manufacturers with rigorous testing protocols, such as those with BBA certification and ICC-ES reports, generally offer documented longevity and performance consistency.

What is the proper way to handle seams and overlaps?

Proper seam and overlap treatment is critical for creating a continuous water-resistant barrier. For vertical seams, overlap typically should be 4-6 inches, while horizontal seams should have a minimum 6-inch overlap configured in a shingle fashion (upper layer overlapping lower layer). All seams should be sealed with manufacturer-recommended tape specifically designed for the membrane type. The substrate should be clean and dry before taping, and pressure should be applied along the entire taped seam to ensure complete adhesion. Never rely on unsealed lapped seams for water protection.

Is house wrap the same as waterproof breathable membrane?

While often used interchangeably, these terms have distinct meanings. All high-quality house wraps are waterproof breathable membranes, but not all waterproof breathable membranes are house wraps. House wrap specifically refers to membranes designed for wall applications beneath cladding. Waterproof breathable membrane is a broader category that includes products for roofs, foundations, and other applications. The performance requirements, durability, and installation methods may differ significantly between these specialized products, so it's important to select the specific membrane designed for your application.

Can I install siding directly over waterproof breathable membrane?

Generally yes, but with important considerations. Most siding manufacturers require a waterproof breathable membrane behind their product, but specific clearance and fastening requirements vary. Many building codes now require a drainage space between the membrane and siding to allow any incidental moisture to drain downward and out. This is typically achieved using vertical furring strips or specialized drainage mats. Always consult both the membrane and siding manufacturer installation instructions to ensure compatibility and proper water management detailing.

What maintenance is required after installation?

Properly installed waterproof breathable membrane requires minimal maintenance, but periodic inspections are recommended. Check for tears, loose fasteners, or failed seams, particularly after severe weather events. Ensure that the membrane remains protected from prolonged UV exposure, as most membranes are not designed for extended sunlight contact. Keep the area around the building foundation clear to prevent insect or rodent damage to the membrane. Any penetrations made after initial installation, such as for new utilities or fixtures, must be properly flashed and sealed to maintain the integrity of the water-resistant barrier.

日本語

日本語 Русский

Русский España

España عرب .

عرب .