Why Do Waterproof and Breathable Membranes Fail? Understanding the Root Causes

2025-10-30

The failure of Waterproof Air Permeable Membrane systems can lead to catastrophic building envelope problems, including moisture damage, mold growth, structural deterioration, and significant energy inefficiency. While these advanced materials are engineered to provide decades of reliable service, various factors can compromise their performance over time. Understanding why waterproof breathable membranes fail is crucial for architects, builders, and property owners seeking to prevent costly repairs and maintain building integrity. This comprehensive analysis explores the primary failure mechanisms and provides insights into proper material selection, installation, and maintenance practices.

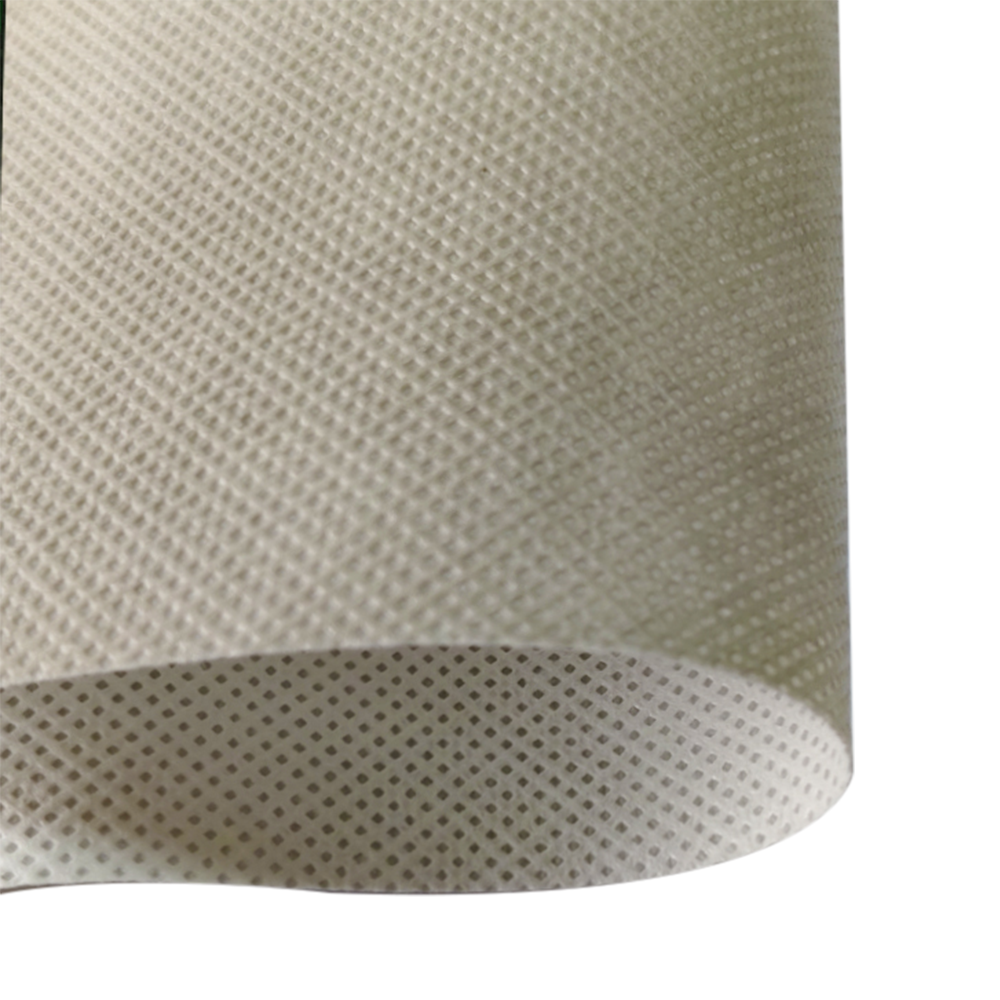

SFS non-woven PP breathable membrane for roof underlayment T150

Material Degradation: When the Membrane Itself Breaks Down

Material degradation represents one of the most fundamental reasons for waterproof breathable membrane failure. Even high-quality membranes can deteriorate when exposed to conditions beyond their design parameters. This degradation can manifest as chemical breakdown, physical damage, or altered performance characteristics that undermine the membrane's core functionality. Understanding the different degradation mechanisms helps in selecting appropriate materials for specific environmental conditions and applications.

- UV Radiation Damage: Prolonged exposure to ultraviolet light can break down polymer chains, causing embrittlement, cracking, and reduced tensile strength.

- Chemical Incompatibility: Exposure to incompatible chemicals from adjacent building materials, cleaning agents, or environmental pollutants can cause swelling, softening, or dissolution of membrane components.

- Thermal Cycling Stress: Repeated expansion and contraction due to temperature fluctuations can cause fatigue cracking, particularly at stress points and fasteners.

- Biological Growth: Mold, fungi, or bacterial colonization can degrade certain membrane materials, particularly those with organic components or plasticizers.

UV Degradation and Weathering Effects

Ultraviolet radiation represents one of the most significant environmental threats to waterproof breathable membranes, particularly those left exposed for extended periods before cladding installation. The photochemical degradation process breaks down polymer structures, fundamentally changing the material's physical properties and performance characteristics.

- Surface Embrittlement: UV exposure typically begins degrading the membrane surface first, creating a brittle layer that cracks under minimal stress.

- Color Changes: Fading or chalking indicates UV degradation has begun, often preceding more serious structural damage.

- Reduced Flexibility: The membrane loses its ability to accommodate building movement, leading to stress cracking at fastened areas.

- Performance Compromise: Both waterproofing and breathability can be negatively affected as the polymer structure deteriorates.

| Degradation Type | Visible Signs | Performance Impact |

| UV Degradation | Brittleness, discoloration, surface cracking | Reduced tensile strength, cracking |

| Chemical Attack | Swelling, softening, sticky surface | Loss of waterproof integrity |

| Thermal Fatigue | Micro-cracks at fasteners, seam separation | Water infiltration at stress points |

| Biological Growth | Visible mold, staining, odor | Material decomposition, health concerns |

Installation Errors: The Human Factor in Membrane Failure

Improper installation represents the most common cause of premature waterproof breathable membrane failure. Even the highest quality membrane cannot perform as designed when installed incorrectly. These errors often create pathways for water intrusion, compromise breathability, or generate stress points that lead to premature deterioration. Recognizing common installation mistakes enables proactive quality control during construction and helps prevent costly failures.

- Incorrect Fastening Practices: Over-driven, under-driven, or incorrectly spaced fasteners can create stress concentrations, tearing, or inadequate holding power.

- Improper Seam Management: Insufficient overlap, inadequate sealing, or misaligned seams create direct pathways for water intrusion.

- Wrong-Side Installation: Installing the membrane with the wrong surface facing outward compromises its directional performance properties.

- Inadequate Integration with Flashings: Poor detailing at penetrations, corners, and transitions creates vulnerable areas for water entry.

Critical Seam and Lap Failures

Seam and lap failures represent a particularly prevalent installation error that directly leads to waterproof breathable membrane problems. These failures typically result from inadequate understanding of water management principles or rushing the installation process without proper attention to detail.

- Insufficient Overlap: Using less than the manufacturer-recommended overlap (typically 4-6 inches for vertical seams, 6 inches for horizontal) creates capillary breaks.

- Unsealed or Improperly Sealed Seams: Failure to use manufacturer-recommended tape or applying tape to dirty, damp, or cold surfaces.

- Reverse Lapping: Installing upper layers behind lower layers rather than overlapping in a shingle fashion that sheds water outward.

- Wrinkles and Folds in Seam Areas: Creating channels that direct water behind the membrane rather than away from the building.

Design and Specification Flaws: Systemic Causes of Failure

Sometimes, waterproof breathable membrane failure originates not at the jobsite but during the design and specification phase. Incompatible material combinations, incorrect product selection for specific climate conditions, or flawed system designs can doom a membrane to underperformance from the outset. These systemic issues often affect entire building envelopes rather than isolated areas, making them particularly problematic to address.

- Climate Incompatibility: Specifying membranes with inappropriate vapor permeability for the local climate zone leads to condensation issues.

- Material Incompatibility: Combining membranes with incompatible adjacent materials that cause chemical degradation or physical damage.

- Inadequate Drying Potential: Designing assemblies that trap moisture rather than allowing it to escape, overwhelming the membrane's capabilities.

- Missing or Incorrect Details: Failing to provide comprehensive detailing for complex geometry, penetrations, and transitions.

Climate Zone Mismatch and Vapor Drive Confusion

One of the most common design-related causes of waterproof breathable membrane problems involves misunderstanding vapor drive principles and climate-specific requirements. This fundamental error can create chronic moisture issues that persist despite otherwise proper installation.

- Cold Climate Errors: Using highly vapor-permeable membranes on the interior side in cold climates can lead to interstitial condensation within wall assemblies.

- Hot-Humid Climate Mistakes: Specifying low-permeability membranes in positions that trap moisture inside air-conditioned buildings in humid climates.

- Mixed Climate Challenges: Failing to account for seasonal vapor drive reversal in climates with both heating and cooling seasons.

- Vapor Barrier Misapplication: Installing vapor barriers where vapor-permeable membranes are needed, or vice versa, creating moisture traps.

| Design Flaw | Resulting Problem | Solution Approach |

| Climate incompatibility | Chronic condensation, mold growth | Climate-appropriate permeability selection |

| Material incompatibility | Chemical degradation, premature failure | Compatibility testing, separation barriers |

| Inadequate drying potential | Moisture accumulation, rot | Balanced assembly design, ventilation |

| Missing critical details | Localized failures at complex geometry | Comprehensive detailing, mockups |

Environmental and Structural Stress Factors

Beyond material and installation issues, waterproof breathable membrane failure can result from environmental conditions and structural movements that exceed the material's design capacity. These factors often act gradually over time, making early detection challenging until significant damage has occurred. Understanding these stress factors enables better material selection and implementation of protective measures.

- Wind Load Exceedance: Sustained high winds or extreme wind events can cause billowing, tearing, or fastener pull-out.

- Structural Movement: Settlement, seismic activity, or thermal expansion/contraction of building frames can stress membranes beyond their elongation capacity.

- Freeze-Thaw Cycling: Repeated freezing of trapped moisture creates expansion forces that can separate layers, break seams, or cause punctures.

- Impact Damage: Construction activities, falling debris, or maintenance operations can puncture or tear membranes.

Maintenance and Repair Oversights

Even properly installed waterproof breathable membranes can fail when maintenance is neglected or repairs are performed incorrectly. Unlike some building components that can be "install and forget," membranes require periodic inspection and appropriate response to damage. Unfortunately, maintenance is often overlooked until failure becomes evident through interior water damage or energy performance degradation.

- Lack of Periodic Inspection: Failing to identify and address minor damage before it escalates into major failures.

- Improper Repair Techniques: Using incompatible patching materials or techniques that create new problems while solving existing ones.

- Unapproved Modifications: Making penetrations or attachments after initial installation without proper flashing and sealing.

- Cladding System Failures: Damaged or deteriorated exterior cladding that exposes membranes to conditions beyond their design parameters.

Proper Inspection and Maintenance Protocols

Implementing a systematic approach to waterproof breathable membrane maintenance can significantly extend service life and prevent catastrophic failures. Regular inspections and timely, appropriate repairs are investments that pay dividends in long-term building performance and avoided repair costs.

- Scheduled Inspection Intervals: Conduct comprehensive inspections annually and after severe weather events.

- Documentation System: Maintain records of inspection findings, repairs, and membrane performance over time.

- Qualified Repair Personnel: Ensure repairs are performed by individuals trained in proper membrane repair techniques.

- Manufacturer Consultation: Contact membrane manufacturers for technical support when addressing complex repair scenarios.

Prevention Strategies: Avoiding Common Failure Scenarios

Preventing waterproof breathable membrane failure requires a systematic approach addressing material selection, design, installation, and maintenance. By understanding the common failure mechanisms, building professionals can implement proactive measures that significantly reduce failure risk. The most effective prevention strategy involves multiple layers of protection rather than relying solely on any single approach.

- Comprehensive Specification: Select membranes with appropriate certifications (BBA, ICC-ES) and proven performance in similar applications.

- Quality Assurance Programs: Implement third-party inspection during critical installation phases to verify compliance with manufacturer instructions.

- Education and Training: Ensure installation crews receive product-specific training and understand the consequences of improper installation.

- Lifecycle Planning: Develop maintenance plans during design phase, including inspection schedules and repair protocols.

FAQ

How can I tell if my waterproof breathable membrane is failing?

Recognizing early signs of waterproof breathable membrane failure can prevent extensive damage. Visible indicators include water stains on interior surfaces, mold or mildew growth, peeling paint or wallpaper, and musty odors. On the exterior, look for bubbling, wrinkling, or sagging of the membrane; visible tears or punctures; deteriorated seams or tape; and excessive dirt accumulation indicating moisture trapping. Energy bill increases can also signal compromised thermal performance due to wet insulation. Professional inspection using infrared thermography can detect hidden moisture before visible damage appears.

What is the typical warranty period for waterproof breathable membranes?

Warranty periods for waterproof breathable membranes vary significantly by manufacturer and product type, typically ranging from 10 to 30 years. However, it's crucial to understand that warranties often have specific conditions regarding proper installation, maintenance, and compatibility with other system components. Many warranties pro-rate over time and may exclude certain types of damage. Manufacturers with robust testing programs, such as those with BBA certification and ICC-ES reports, often back their products with more comprehensive warranties, reflecting confidence in their product's long-term performance.

Can failed waterproof breathable membrane be repaired, or does it require complete replacement?

Many waterproof breathable membrane problems can be successfully repaired without complete replacement, depending on the failure's extent and nature. Localized damage such as small tears, punctures, or failed seams can typically be repaired using manufacturer-approved patching materials and techniques. However, widespread degradation, extensive UV damage, or systemic installation errors usually require complete membrane replacement. The repair approach should always follow manufacturer recommendations to maintain system compatibility and performance. For extensive damage, consultation with a building envelope specialist is recommended to assess whether repair or replacement is the most appropriate solution.

Does building movement affect waterproof breathable membrane performance?

Yes, building movement significantly impacts waterproof breathable membrane performance and longevity. All buildings experience movement from thermal expansion and contraction, settlement, wind sway, and seismic activity. Membranes must accommodate this movement through adequate flexibility and proper installation techniques that avoid creating stress points. Failure to account for building movement can cause tearing at fasteners, seam separation, and fatigue cracking. Membrane selection should consider the specific movement characteristics of the building system, with appropriate allowances for expected dimensional changes over the structure's lifespan.

How does temperature extremes affect membrane performance?

Temperature extremes impact waterproof breathable membranes in multiple ways. In cold conditions, membranes become stiffer and more brittle, increasing susceptibility to cracking during installation or from building movement. Freezing temperatures can affect adhesive properties of tapes and sealants. In high heat, some membranes may become overly soft, potentially sagging or deforming, while UV degradation accelerates. Temperature cycling causes expansion and contraction that can lead to fatigue failure at fastened points. Quality membranes are engineered to maintain performance across expected temperature ranges, but proper selection for specific climate conditions remains essential.

Are there signs during installation that might predict future membrane failure?

Yes, several installation red flags can predict future waterproof breathable membrane failure. These include visible wrinkles or folds that create water channels, inadequate fastener spacing or over-driven fasteners, insufficient seam overlaps, tape applied to dirty or damp surfaces, membrane installed during inclement weather, and lack of proper integration with flashings at penetrations. Additionally, storing membranes in direct sunlight before installation, walking on installed membrane without protection, and failing to immediately address accidental punctures during construction are all practices that compromise long-term performance. Quality assurance during installation is the most effective strategy for identifying and correcting these issues before they lead to failure.

日本語

日本語 Русский

Русский España

España عرب .

عرب .