Waterproof and Breathable Membranes: Microporous vs. Non-Porous Structures

2025-10-17

In the world of building materials and protective fabrics, the Waterproof Air Permeable Membrane stands as a critical innovation. These advanced materials allow water vapor to escape while preventing liquid water from penetrating, creating drier, healthier, and more energy-efficient structures. The performance of these membranes hinges on their internal structure, primarily categorized as microporous or non-porous (monolithic). Understanding the distinction is crucial for selecting the right material for your project, whether it's a high-performance building envelope or specialized medical protective gear.

Understanding the Core Technology: How Waterproof Breathable Membranes Work

At its heart, a Waterproof Air Permeable Membrane functions based on a fundamental physical principle: the difference in size between water vapor molecules and liquid water droplets. These membranes are engineered to create a barrier that exploits this size difference. The technology is not about creating a completely sealed environment but rather a smart, selective barrier that manages moisture and air flow intelligently. This is essential for preventing mold, rot, and structural degradation while maintaining comfort and energy efficiency.

- Moisture Management: The primary role is to prevent bulk water ingress from rain or spills while allowing internally generated water vapor (from occupants, activities, etc.) to diffuse out.

- Energy Efficiency: By keeping the insulation dry, these membranes help maintain its thermal resistance (R-value), reducing heating and cooling costs.

- Durability: They protect building components and materials from water damage, extending the lifespan of the entire structure.

- Air Tightness: Many of these membranes also contribute to a building's air barrier system, reducing drafts and energy loss.

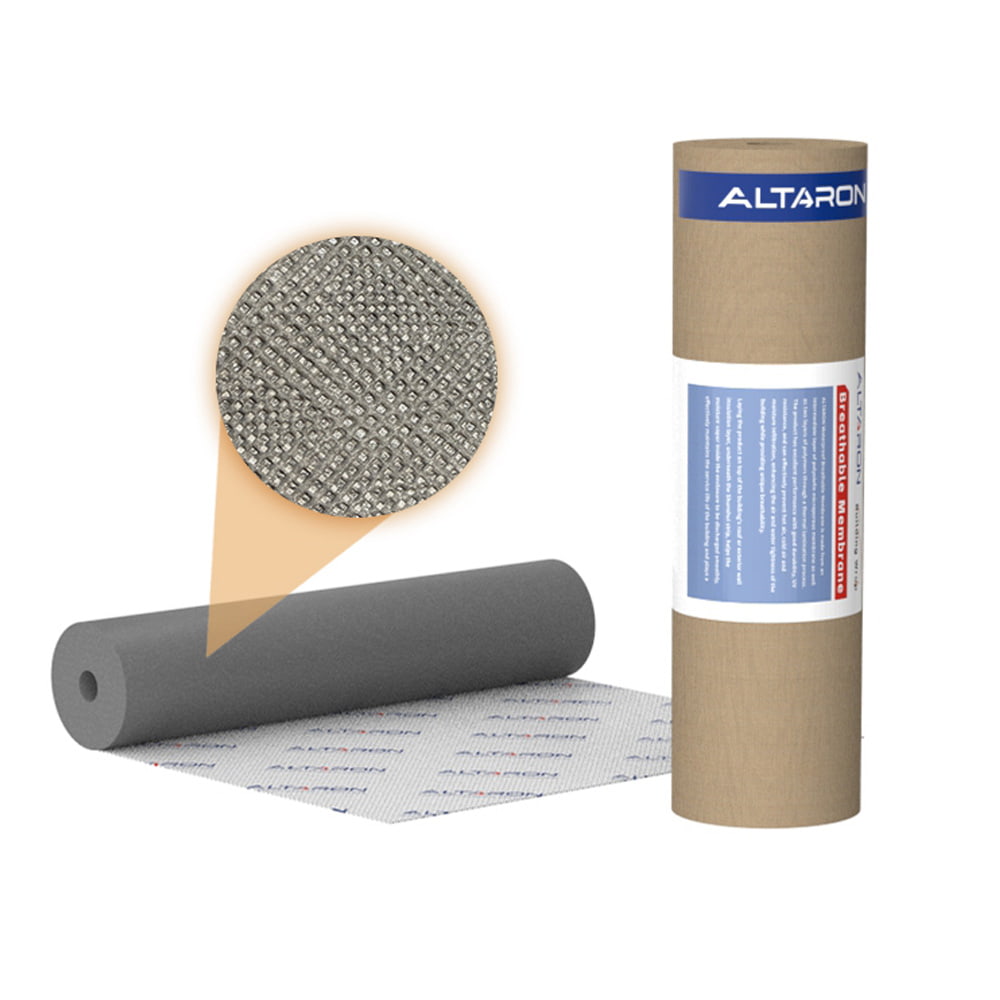

Microporous Membranes: The Traditional Powerhouse

A microporous waterproof breathable membrane operates like a miniature sieve. It contains billions of tiny, interconnected pores per square centimeter. These pores are large enough to allow water vapor molecules (which are very small) to pass through via diffusion but are too small for liquid water droplets to penetrate due to surface tension. This structure is highly effective and has been the go-to technology for decades in many applications, from rainwear to house wraps. The key to its performance is the precise engineering of the pore size distribution.

- High Breathability: Typically offers excellent moisture vapor transmission rates (MVTR), making it ideal for high-humidity environments.

- Instant Activation: The breathability is a physical property of the structure and does not require a temperature gradient to start working.

- Material Composition: Often made from polypropylene (PP) or polytetrafluoroethylene (PTFE) that is stretched or processed to create the micro-pores.

- Potential Vulnerability: The pores can theoretically become contaminated or blocked by dirt, oils, or certain chemicals, which may reduce performance over time.

Key Applications for Microporous Membranes

Due to their robust and immediate breathability, microporous membranes are the preferred choice in several demanding sectors. Their ability to handle large volumes of vapor makes them indispensable in both construction and personal protection.

- Roofing Underlayments: Used beneath tiles or metal roofing to protect against wind-driven rain while allowing the roof structure to breathe.

- Wall and Building Wrap: A staple in modern construction, these wraps protect the building frame during construction and serve as a long-term weather-resistant barrier.

- Specialized Medical and Protective Clothing: Where high levels of vapor transmission are needed to maintain wearer comfort without compromising liquid barrier protection.

Non-Porous (Monolithic) Membranes: The Advanced Alternative

In contrast, a non-porous monolithic breathable membrane has no physical pores. Instead, it is a solid, continuous film, typically made from polyurethane (PU) or thermoplastic polyurethane (TPU). Breathability is achieved through a process called adsorption-diffusion-desorption. Water vapor molecules are absorbed into the solid polymer matrix on the humid side, diffuse through it driven by a concentration gradient, and are then released (desorbed) on the drier side. This "molecular shuttle" mechanism is highly effective and inherently resistant to external contaminants.

- Superior Durability and Pore-Free: Being a solid film, it is inherently immune to clogging from dirt, detergents, or chemicals, making it extremely reliable.

- Absolute Waterproofing: Provides a 100% continuous barrier against liquid water, as there are no pores to potentially wet out.

- Activation Energy: The diffusion process often works best with a temperature and humidity gradient, meaning performance can increase as the difference between inside and outside conditions grows.

- Flexibility and Comfort: Often softer and more flexible than microporous laminates, making them a favorite for high-end apparel.

Where Non-Porous Membranes Excel

The unique properties of non-porous membranes make them the superior choice in applications where absolute reliability and resistance to challenging environments are paramount.

- Medical Protective Apparel: Ideal for surgical gowns and drapes where protection against blood and viral pathogens is critical, and the membrane cannot risk being compromised by bodily fluids or cleaning agents.

- Construction Vapor Barriers: Used on the warm-in-winter side of insulation to prevent interstitial condensation, their monolithic structure provides a guaranteed seal.

- High-End Technical Apparel: Used in garments designed for consistently harsh and wet conditions, such as ski wear and sailing gear, where long-term waterproof integrity is non-negotiable.

Microporous vs. Non-Porous: A Detailed Comparison

Choosing between a microporous and a non-porous membrane is not about finding the "best" technology, but the most suitable waterproof breathable membrane for the specific application. The decision matrix involves factors like the primary threat (liquid water vs. vapor), the environment, required durability, and budget. Manufacturers like Jiangsu Aotelong New Materials Co., Ltd. often produce both types to cater to the diverse needs of the global market, from construction to medical fields, ensuring there is a optimized solution for every scenario.

- Breathability Mechanism: Microporous relies on physical pores; Non-porous relies on molecular diffusion through a solid polymer.

- Liquid Barrier: Both are excellent, but non-porous offers an absolute barrier as it has no pores to potentially fail.

- Durability Against Contaminants: Non-porous membranes generally have higher chemical resistance and are not susceptible to pore clogging.

- Breathability Response: Microporous works instantly; Non-porous often improves with a stronger temperature/humidity gradient.

| Feature | Microporous Membrane | Non-Porous Membrane |

| Breathability Mechanism | Physical pores | Molecular diffusion |

| Liquid Water Resistance | Excellent | Absolute |

| Durability (Clogging) | Potentially vulnerable | Highly resistant |

| Typical Applications | House wraps, roofing underlayment | Medical gowns, vapor barriers |

| Best For | High vapor transmission needs | Harsh chemical environments |

Selecting the Right Membrane for Your Project

Making the final choice requires a careful evaluation of your project's specific demands. For those seeking a waterproof breathable membrane for roof that needs to handle sudden rain during construction and long-term vapor drive, a microporous option might be ideal. Conversely, for a critical application like a medical waterproof breathable film that cannot fail under exposure to contaminants, a non-porous membrane is unequivocally the safer choice. Consulting with technical data sheets from manufacturers is a vital step in this process.

- Assess the Primary Risk: Is it bulk water (rain), vapor (condensation), or both?

- Consider the Environment: Will the membrane be exposed to dirt, chemicals, or UV radiation?

- Check Performance Data: Look for tested metrics like Water Entry Pressure (hydrostatic head) and Moisture Vapor Transmission Rate (MVTR).

- Regulatory and Certification Needs: Ensure the product meets relevant standards for your industry (e.g., BBA certification for construction, CE for medical).

Key Performance Metrics to Consider

When reviewing products, whether for a waterproof breathable membrane for walls or other uses, focus on these tested performance indicators to make an objective comparison.

- Water Resistance (Hydrostatic Head): Measured in mm, it indicates the pressure of water the membrane can withstand before leaking. A higher number is better.

- Moisture Vapor Transmission Rate (MVTR): Measured in g/m²/24hrs, it quantifies how much water vapor can pass through. A higher number indicates better breathability.

- Air Permeability: Measures the volume of air passing through the material. Some membranes are designed to be air barriers, while others are not.

- Durability Tests: Look for tests for UV resistance, tear strength, and dimensional stability.

FAQ

What is the typical lifespan of a waterproof breathable membrane in a building?

The lifespan of a Waterproof Air Permeable Membrane is designed to match the service life of the building component it protects. High-quality membranes, when installed correctly and not exposed to prolonged UV radiation, can last the lifetime of the building envelope—often 50 years or more. The durability is a function of the polymer used (e.g., PP, PU) and the inclusion of UV stabilizers. Manufacturers like Jiangsu Aotelong New Materials Co., Ltd. subject their products to rigorous accelerated aging tests to ensure long-term performance, a critical factor for sustainable construction.

Can a waterproof breathable membrane be used as a primary air barrier?

This depends entirely on the specific product. Some waterproof breathable membranes are explicitly designed and tested to function as both a water-resistant barrier and an air barrier. These products will have a very low air permeability rating. However, not all membranes are created equal. A standard microporous house wrap might allow some air passage. It is crucial to check the manufacturer's technical data to confirm if a product is rated as an air barrier, especially when designing for high-performance or passive house standards where airtightness is a key requirement.

How does temperature affect the performance of non-porous membranes?

Temperature has a more pronounced effect on non-porous monolithic breathable membrane performance compared to microporous types. The adsorption-diffusion-desorption process is thermally activated. As the temperature increases, the polymer chains become more mobile, which significantly increases the rate of vapor diffusion. This means a non-porous membrane will generally be more breathable on a warm, humid day than on a cold one. This is often a good match for building physics, as the need for vapor egress is typically higher in warmer conditions.

What is the difference between a breathable membrane and a vapor barrier?

This is a fundamental distinction. A waterproof breathable membrane is designed to be permeable to water vapor (breathable) while blocking liquid water. It is typically used on the cold side of insulation (e.g., behind siding, under roofing) to let the structure dry out. A vapor barrier, or more accurately a vapor retarder, is designed to be highly resistant to water vapor and is installed on the warm-in-winter side of insulation (e.g., behind drywall) to prevent warm, moist indoor air from condensing within the wall cavity. Some non-porous membranes can function as vapor barriers due to their very low permeance.

Are there environmentally friendly or sustainable options for waterproof breathable membranes?

Yes, the industry is increasingly focused on sustainability. Innovations include membranes made from recycled materials, bio-based polymers, and products that are fully recyclable. The inherent energy-saving benefit of these membranes—by keeping insulation dry and effective—also contributes significantly to a building's overall lifecycle sustainability. Leading companies are investing in this area; for instance, Jiangsu Aotelong New Materials Co., Ltd. emphasizes its commitment to creating "high-quality, environmentally friendly, and energy-saving products," aligning with global trends in green building and responsible manufacturing.

日本語

日本語 Русский

Русский España

España عرب .

عرب .