Reflective Vapour Barrier: A Comprehensive Guide to Installation and Benefits

2025-10-09

When it comes to building an energy-efficient and durable structure, managing moisture and heat is paramount. A reflective vapour barrier is a advanced material designed to address both of these concerns simultaneously. Unlike traditional barriers, it not only prevents moisture diffusion—which can lead to mold, rot, and structural damage—but also reflects radiant heat, enhancing the thermal performance of your building envelope. This dual-action makes it a critical component in modern construction, particularly in attics, crawl spaces, and walls. Understanding its proper application, benefits, and how it compares to other materials is essential for homeowners, builders, and architects alike. This guide will delve deep into the specifics, providing you with the knowledge needed to make an informed decision for your project.

What is a Reflective Vapour Barrier and How Does It Work?

A reflective vapour barrier is a multifaceted building material typically composed of a foam or fabric core laminated between one or two layers of highly reflective foil, often aluminum. The core provides some insulation value and structural integrity, while the foil layer acts as a radiant barrier, reflecting up to 97% of radiant heat back towards its source. This helps keep buildings cooler in summer and warmer in winter. Crucially, the material is also engineered to have a very low perm rating, meaning it is highly resistant to the passage of water vapor. This combination is what sets it apart. The science behind it involves two key principles: radiant heat transfer and vapour diffusion control.

- Radiant Heat Control: The shiny foil surface reflects thermal radiation, unlike traditional insulation which only resists conductive heat flow.

- Vapour Diffusion Resistance: The tight structure of the material prevents water vapor from warm, humid indoor air from migrating into cooler wall or attic cavities where it can condense.

- Air Barrier Properties: When properly sealed with specialized tapes, it can also function as an effective air barrier, preventing drafts and energy loss.

Key Differences from Standard Vapor Barriers

It's important to distinguish a reflective vapour barrier from the standard polyethylene plastic sheeting commonly used. While both control moisture, their approach to thermal management is fundamentally different. A standard poly barrier is a passive component, only blocking vapour. A reflective barrier is an active component in your insulation system, contributing directly to the R-value and overall energy efficiency.

| Feature | Reflective Vapour Barrier | Polyethylene Sheeting |

| Primary Function | Blocks vapour & reflects radiant heat | Blocks vapour only |

| Thermal Performance | Enhances effective R-value of insulation | No direct thermal benefit |

| Material | Foil-faced foam or fabric | Plastic film |

| Perm Rating | Extremely low (typically < 0.1 perm) | Low (typically < 1.0 perm) |

| Ideal Climate | Mixed and hot-humid climates | Cold climates |

Top Benefits of Installing a Reflective Vapour Barrier

The installation of a reflective vapour barrier offers a multitude of advantages that extend beyond basic moisture protection. These benefits translate into tangible improvements in comfort, cost savings, and the longevity of the building. For those considering benefits of reflective insulation, the value proposition is clear. The initial investment is often offset by long-term energy savings and reduced risk of costly repairs due to moisture damage.

- Superior Energy Efficiency: By reflecting radiant heat, the barrier reduces the load on HVAC systems, leading to lower utility bills.

- Enhanced Moisture Control: Effectively prevents condensation within walls and roofs, protecting against mold growth and wood rot.

- Improved Indoor Comfort: Helps maintain more consistent temperatures throughout the building, eliminating hot or cold spots.

- Increased Durability: By safeguarding the building structure from moisture, it extends the life of other building materials like wood framing and insulation.

How to Install a Reflective Vapour Barrier Correctly

Proper installation is critical to the performance of a reflective vapour barrier. An incorrect installation can compromise its ability to control moisture and reflect heat, and may even trap moisture inside wall assemblies. The process requires attention to detail, the right materials, and an understanding of the building's climate zone. The question of how to install reflective vapour barrier is one of the most searched, highlighting its importance to DIYers and professionals.

- Identify the Warm Side: The barrier must always be installed on the "warm-in-winter" side of the insulation. In most climates, this is the interior side.

- Create an Air-Tight Seal: All seams, edges, and penetrations (like around electrical boxes) must be sealed with a compatible foil tape or mastic. This is non-negotiable for performance.

- Maintain Proper Clearance: For the reflective surface to work, it needs an air space of at least 3/4 of an inch facing the reflective side. Do not bury it under another material.

Common Installation Mistakes to Avoid

Many well-intentioned installations fail due to a few common errors. Awareness of these pitfalls can save time, money, and prevent potential damage to the building.

- Installing on the Wrong Side: Placing the barrier on the cold side of the insulation can cause condensation within the wall cavity.

- Using Duct Tape for Seams: Standard duct tape will fail over time. Only use tapes specifically designed for this application.

- Compressing the Material: Avoid compressing the barrier, as this can reduce its effectiveness and the necessary air gap.

Reflective Vapour Barrier vs. Radiant Barrier: Understanding the Difference

A common source of confusion is the difference between a reflective vapour barrier and a standalone radiant barrier. While they share a reflective component, their core functions are distinct. This is a key point of comparison for anyone researching reflective vapour barrier vs radiant barrier.

A radiant barrier's sole purpose is to reflect radiant heat. It is often perforated and does not necessarily have a low perm rating, meaning it allows some water vapor to pass through. A reflective vapour barrier, however, is a hybrid product designed to be both a high-performance vapour barrier and a radiant barrier. The choice between them depends on your specific moisture control needs.

| Aspect | Reflective Vapour Barrier | Radiant Barrier |

| Vapour Control | Yes (Primary Function) | No or Minimal (may be perforated) |

| Radiant Heat Control | Yes (Primary Function) | Yes (Primary Function) |

| Perm Rating | Very Low (≤ 0.1 perm) | Can be higher (≥ 5 perms for perforated) |

| Best Use Case | Where both moisture and heat are concerns | Primarily in hot climates for attic applications |

Choosing the Best Reflective Vapour Barrier for Your Home

Selecting the right product is crucial for achieving desired performance. With various options on the market, knowing what to look for will ensure you get a product that meets your needs for durability, R-value, and ease of installation. When searching for the best reflective vapour barrier, consider factors beyond just price.

- R-Value: Some reflective barriers have an integrated foam core that provides additional conductive insulation (e.g., R-3 to R-6).

- Durability and Puncture Resistance: Look for a robust facing and a strong core that can withstand installation and potential impacts.

- Fire Rating: Ensure the product has a Class A/Class 1 fire rating for safety, especially in residential applications.

- Ease of Sealing: Some products come with integrated tape strips or are designed with specific companion tapes for easier air sealing.

Key Specifications to Compare

When comparing products, always check the technical data sheet for these key metrics.

- Perm Rating: Should be 0.1 perm or lower to qualify as a true vapour barrier.

- Reflectivity: Typically 95% or higher for premium products.

- Emissivity: Should be very low (e.g., 0.03 or 0.05), indicating the surface does not re-radiate absorbed heat well.

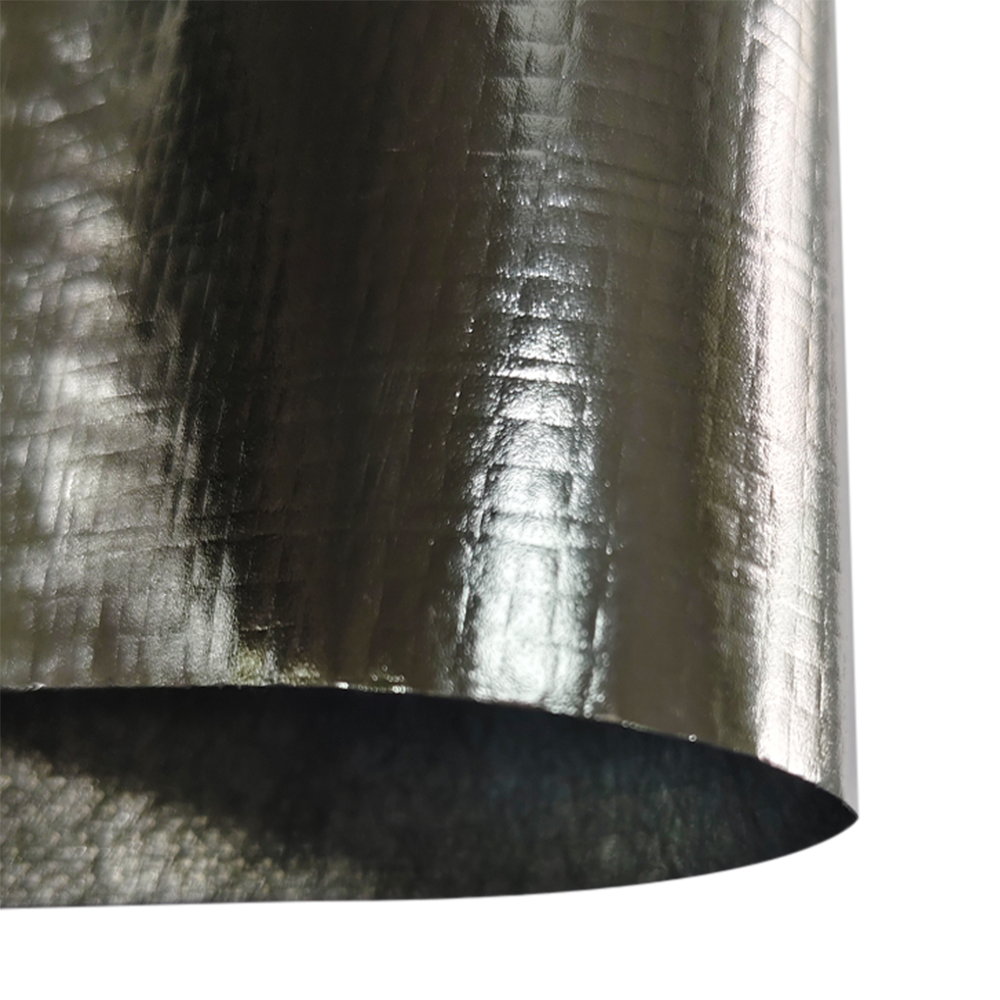

Black Multilayer Composite Reflective Film AWN140

FAQ

Is a reflective vapour barrier necessary in a cold climate?

Yes, but its application must be carefully considered. In cold climates, the primary concern is preventing warm, moist indoor air from entering the wall assembly and condensing. A reflective vapour barrier is excellent at this. However, it is crucial that it is installed on the interior (warm) side. In some very cold climate constructions, experts may recommend a "smart" vapour retarder (variable perm) instead, which allows the wall to dry to the interior under certain conditions. For most standard cold-climate homes, a properly installed reflective vapour barrier is a highly effective solution.

Can I install a reflective vapour barrier over existing insulation?

This is a complex question. It is generally not recommended to install an interior vapour barrier over existing wall insulation, as it can trap moisture within the wall cavity if the existing assembly is already wet. However, in an attic, it can sometimes be installed over existing insulation on the floor, but only if you can ensure the necessary air gap is maintained on the reflective side and all seams are perfectly sealed. For walls, this is a high-risk procedure and consulting with a building science professional is strongly advised to avoid creating moisture problems.

What is the cost difference between a reflective barrier and a standard poly barrier?

A reflective vapour barrier is significantly more expensive than standard polyethylene sheeting. You can expect to pay 3 to 5 times more per square foot for the material itself. However, this is not a direct apples-to-apples comparison. The reflective barrier provides a thermal function that the poly does not. Therefore, the cost should be evaluated against the overall energy savings it will generate. For many homeowners, the investment is justified by the combined benefit of moisture protection and reduced heating and cooling costs, leading to a reasonable payback period.

Do I need an air gap for a reflective vapour barrier to work?

Absolutely. This is one of the most critical aspects of installation. The reflective surface must face an air space of at least 3/4 inch (19 mm) to effectively reflect radiant heat. If the reflective foil is in direct contact with another material (like drywall or another layer of insulation), its radiant performance is drastically reduced, and it essentially functions only as a vapour barrier. This air gap is what allows the radiant heat transfer to occur, which the barrier then interrupts by reflection.

日本語

日本語 Русский

Русский España

España عرب .

عرب .