Key Technical Characteristics

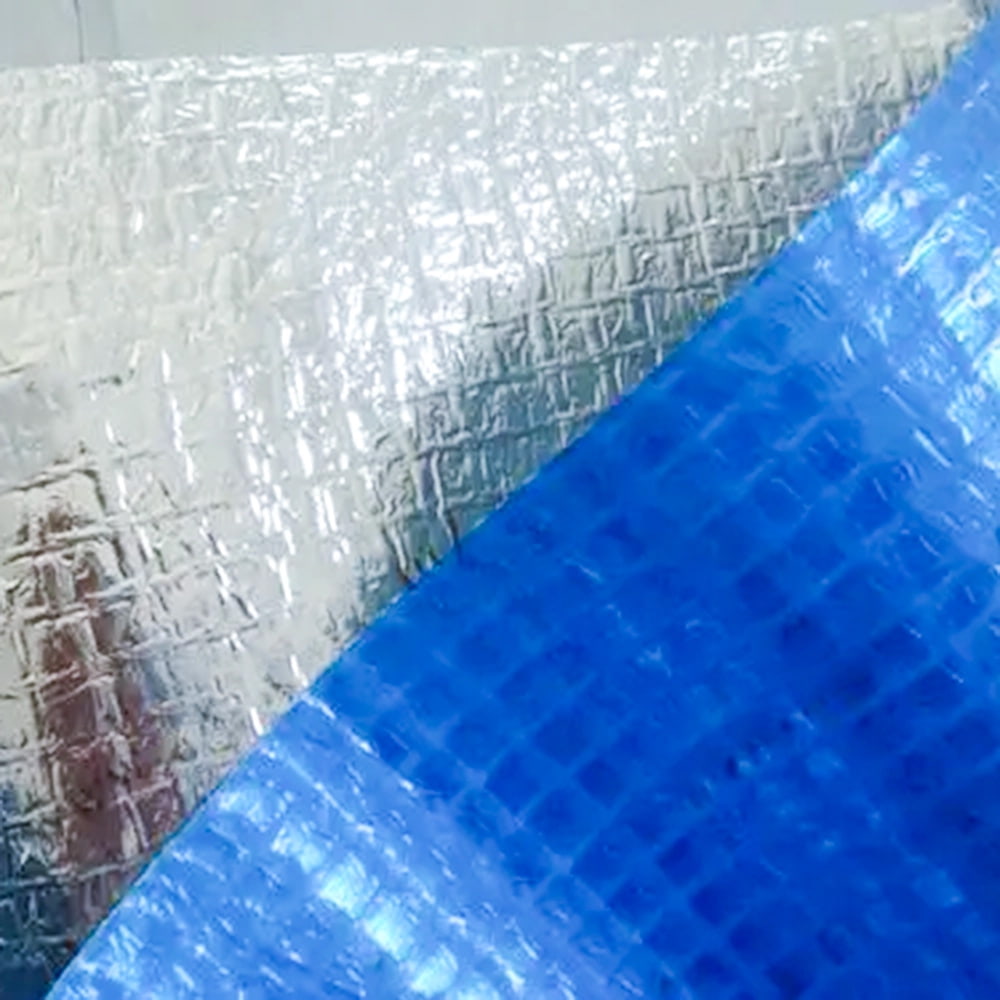

- Layered construction (Al film + PE + reinforced mesh + PE) to combine vapour barrier performance with mechanical reinforcement.

- Reflective surface delivers reduced radiant heat transfer when installed under roof coverings or behind internal wall linings.

- Tear and puncture resistance provided by a continuous mesh scrim to support handling and long-term durability in building applications.

- Low water vapor transmission intended to limit inward or outward moisture migration in conditioned building envelopes.

- Compatible with common adhesive systems and mechanical fasteners used in vapor barrier membrane for roofing and wall assemblies.

Primary Applications

Roofing

Used as an underlayment or interior reflective layer beneath roof insulation to form part of a multilayer thermal control system. When specified as a aluminum foil thermal reflective membrane vapor barrier for roofing, it reduces radiant heat gain into attics and conditioned spaces.

Wall assemblies

Applied to framed wall cavities or masonry inner faces to provide a continuous vapor barrier and to reflect radiant heat from sun-exposed facades. The reinforced mesh supports fastener retention during installation on vertical surfaces.

Other uses

Compatible with HVAC duct wrap facing, sub-roof membranes in warm climates, and retrofit insulation projects where a combined reflective and vapour control layer is required.

Performance Advantages (Technical)

- Reduced radiant heat transfer: Aluminum film surface provides a low-emissivity layer to lower heat flux by radiation across enclosed cavities.

- Controlled vapor permeance: Designed to function as a vapor barrier membrane for building envelope assemblies, limiting moisture transport under typical building conditions.

- Enhanced mechanical strength: Mesh reinforcement improves tear resistance during cutting, handling and fastening, reducing installation defects.

- Compatibility with insulation systems: Can be combined with batt, rigid board and loose-fill insulations without chemical interaction under standard installation conditions.

- Third-party compliance options: Available with factory inspection and testing documentation where required for project specifications.

Installation Guidance

General principles

Install the membrane with the aluminum reflective side oriented toward the air cavity to optimize radiant control. Overlap adjacent sheets per project specification (commonly 50–150 mm) and seal overlapped edges using compatible tapes or mechanically secure with approved fasteners. Ensure continuity across penetrations, junctions and terminations to maintain vapor barrier integrity.

Roof applications

- Lay rolls parallel to the eave-to-ridge direction for pitched roofs; mechanically secure and tape laps.

- Provide a ventilation or drainage plane where required by local codes; consult thermal design documentation when specifying cavity depths.

Wall applications

- Apply to the warm side of insulation in cold climates or per hygrothermal analysis for the project.

- Seal to structural elements using approved sealants and tapes to maintain a continuous air and vapour control layer.

Technical Specifications (Typical values and options)

Values listed below are typical product options. Specific project orders can be supplied with manufacturer test reports and dimensional customization.

| Construction | Aluminum film + PE lamination + Reinforced mesh (scrim) + PE outer layer | Notes |

| Nominal total thickness | 0.20 mm – 0.50 mm | Selectable by order |

| Surface emissivity (reflective face) | < 0.10 (typical) | Measured on reflective side |

| Water vapour transmission (WVTR) | < 0.1 g/m²·24h (typical) / Class: low permeance | Measured per ASTM or ISO methods on request |

| Tensile strength (MD / CD) | ≥ 200 N / 150 N (typical) | Directional values depend on scrim type |

| Tear resistance (Elmendorf or equivalent) | ≥ 120 N (typical) | Reinforced by mesh |

| Puncture resistance | Improved vs. non-reinforced foil films | Measured per project test protocol |

| Operating temperature range | -40 °C to +120 °C (short term +140 °C) | Depends on PE grade |

| Roll width | 0.6 m, 1.0 m, 1.2 m, 1.5 m (custom widths available) | Standard widths for construction use |

| Roll length | 25 m, 50 m, 100 m | Available per order |

| Weight (basis) | 90–220 g/m² (depending on layer thickness) | Specify GSM when ordering |

| Fire performance | Classifications available per national/regional standards | Project-specific documentation provided on request |

| Standard compliance / Certification | ICC-ES factory inspection, UK BBA factory inspection, CE / EN test reports available for select product lines | Request certificates for project submittals |

| Packaging | Core-wound rolls with protective wrapping, palletised | Special packaging for export available |

Ordering and Customization

Custom thickness, scrim density and roll sizes are available for project requirements. Provide the project thermal specification, target vapour permeance, expected installation environment and any applicable code references when requesting a quotation. Pricing and lead times are dependent on order quantity and certification requirements.

Frequently Asked Questions (FAQ)

Q1: Can this membrane be used as a continuous vapor barrier for both roof and wall assemblies?

A1: Yes. When installed according to project specifications and with continuous sealing at laps, penetrations and terminations, the product functions as a vapor barrier membrane for building envelope systems in both roof and wall assemblies. For cold climate applications, placement on the warm side of the insulation should be confirmed by hygrothermal analysis. Jiangsu Aotelong New Materials Co., Ltd. supplies test data and installation guidance to support design decisions and project submittals.

Q2: How does this reflective membrane differ from conventional polyethylene vapor barriers?

A2: The laminated aluminum face provides a low-emissivity surface that reduces radiant heat transfer in addition to limiting convective and diffusive moisture movement. The embedded mesh offers improved mechanical robustness compared with single-layer polyethylene films, reducing the risk of tearing during installation. These combined properties make it suitable for projects that require both radiant control and reinforced mesh vapor barrier performance.

Q3: What certifications and manufacturer support does the supplier provide?

A3: Jiangsu Aotelong New Materials Co., Ltd. is located in Yangzhou City, Jiangsu Province and operates as a vertically integrated manufacturer with R&D, production and sales capabilities. The company’s product portfolio includes vapor barrier membranes, reflective insulation membranes and a range of nonwoven and composite materials. Jiangsu Aotelong has completed factory inspections such as US ICC-ES and UK BBA; select products have test reports from the National Building Materials Testing Center and CE/BBA certification where applicable. Manufacturer documentation, factory inspection reports and third-party test certificates are provided for project procurement and quality assurance.

日本語

日本語 Русский

Русский España

España عرب .

عرب .