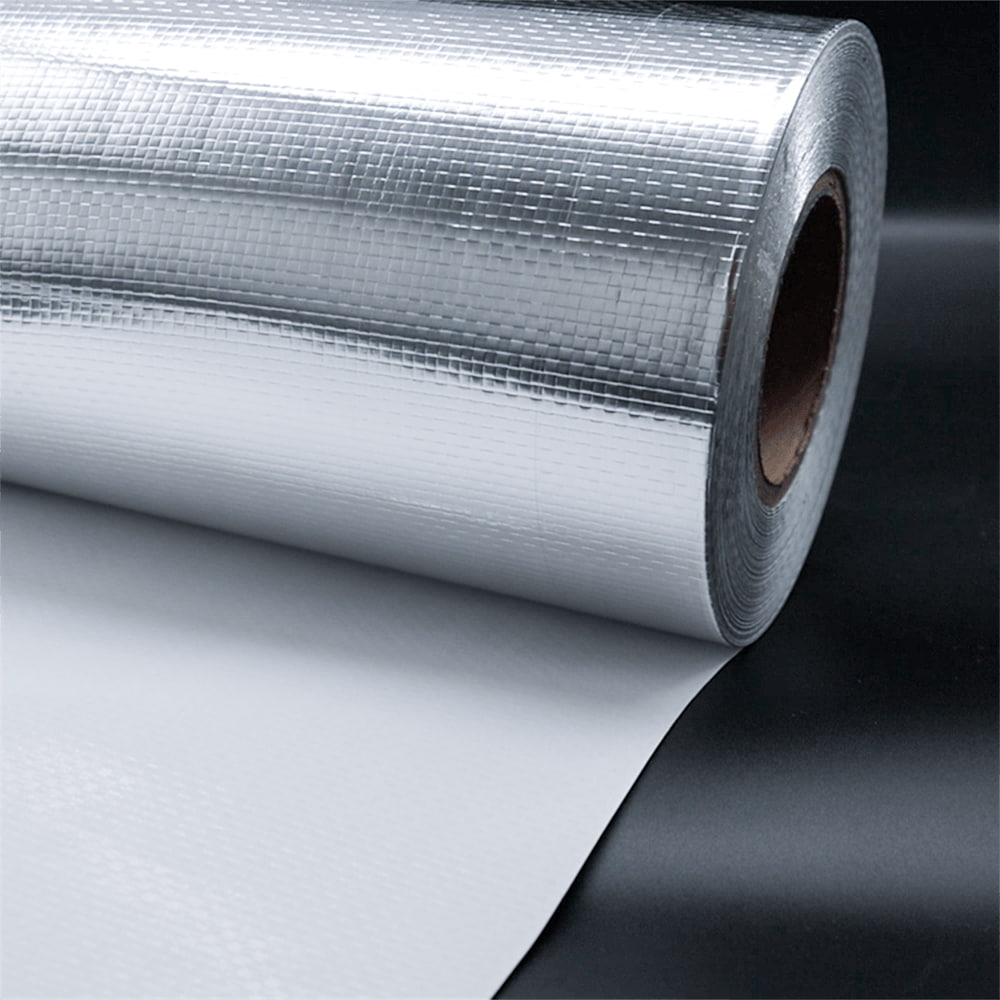

Design and Material Structure

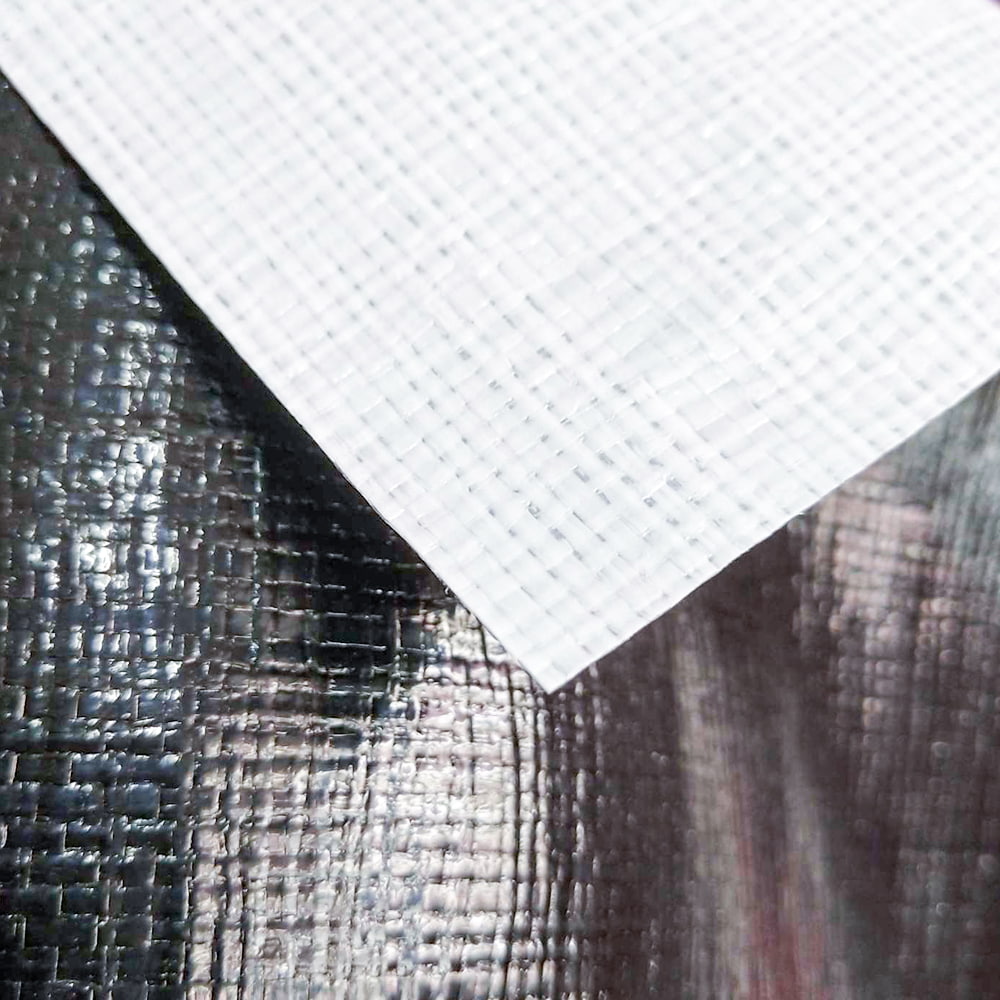

The laminate structure typically comprises, from reflective face to backing: an aluminum metallised film, a PE bonding layer, a woven fabric reinforcement (polypropylene or polyethylene woven scrim) and a protective PE outer layer. This arrangement provides a low-emissivity surface for radiant heat control combined with mechanical reinforcement for handling and fastening.

Key material elements

- Aluminium/metallised film: provides low emissivity and reflective performance for radiant heat reduction.

- PE tie layers: provide lamination integrity and environmental resistance.

- Woven reinforcement: provides tensile strength, puncture resistance and improved fastener retention compared with non-woven alternatives.

Intended Applications

Roofing systems

Used as an underlayment or interior reflective layer in pitched and flat roof systems. When specified as an aluminum foil radiant vapor barrier for roofing, it reduces cavity radiant heat transfer and provides a continuous vapor control layer when correctly sealed.

Wall assemblies

Applied on the warm side of insulation or within cavity wall systems to reduce inward or outward moisture transport and to reflect radiant heat in framed or masonry walls. The woven core supports mechanical fixing on vertical surfaces.

Insulation facings and retrofit

Suitable as a facing for batt and board insulations, as well as for retrofit projects where combined reflective insulation and vapor control are required.

Functional Characteristics

- Radiant heat control via low-emissivity aluminium surface, reducing radiant heat transfer across enclosed cavities.

- Vapour barrier performance with low water vapour transmission rates relative to common polyethylene films.

- Mechanical reinforcement from woven fabric to improve tear and puncture resistance during installation.

- Compatibility with standard fastening and sealing methods used in construction practice.

- Available with project-specific certification and test reports to support procurement requirements.

Installation Guidance

Orientation and placement

Install the reflective face toward the air cavity for optimal radiant control. In cold climates, place the membrane toward the warm side of the insulation unless a hygrothermal model indicates otherwise. Maintain continuous laps and seal edges to achieve an effective vapor barrier membrane.

Sealing and fastening

Overlap adjacent sheets per project specification (typical overlap: 50–150 mm) and apply compatible tapes or sealants. Use mechanical fasteners appropriate for the substrate and avoid concentrated loads on the woven layer. Detail around penetrations, junctions and terminations to preserve air and moisture control performance.

Technical Specifications (Typical values)

Data shown are typical production values. Request project-specific test certificates for contract submittal.

| Layer composition | Aluminum metallised film + PE lamination + woven fabric + PE backing | Custom layer weights available |

| Nominal thickness | 0.18 mm – 0.60 mm | Dependent on aluminium foil gauge and PE layer |

| Surface emissivity (reflective face) | < 0.12 (typical) | Measured per ASTM emissivity methods |

| Water vapour transmission (WVTR) | < 0.15 g/m²·24h (typical) | Measured per ISO/ASTM on request |

| Tensile strength (MD / CD) | ≥ 180 N / 140 N | Depends on woven yarn and weave density |

| Tear resistance | ≥ 100 N (Elmendorf or equivalent) | Reinforced by woven core |

| Puncture resistance | Improved vs. non-woven or film-only membranes | Project testing recommended |

| Operating temperature range | -40 °C to +110 °C (short-term up to +135 °C) | Dependent on PE grade and aluminium layer |

| Standard roll widths | 0.6 m, 1.0 m, 1.2 m, 1.5 m | Custom widths available |

| Standard roll lengths | 25 m, 50 m, 100 m | Delivery options per order |

| Mass per unit area | 100–240 g/m² | Specify GSM on PO |

| Fire performance | Classifications available to meet regional codes | Provide project code for certification scope |

| Certifications | ICC-ES factory inspection; UK BBA inspection; CE/EN reports on selected lines | Certificates supplied on request |

| Packing | Core-wound rolls, protective wrapping, palletised | Export packaging options available |

Ordering and Custom Options

Project-specific options include customised roll widths, adjusted layer thickness, alternate woven densities and specified test reports. When requesting a quotation, provide required thermal targets, target vapour permeance, expected exposure conditions and applicable building code references.

Frequently Asked Questions (FAQ)

Q1: Is this product suitable as a continuous vapor barrier for both roofs and walls?

A1: When installed with continuous sealing at laps, penetrations and terminations, the composite film functions as a vapor barrier membrane for roof and wall assemblies. Project-specific factors such as climate, orientation and insulation placement determine optimal location within the assembly; a hygrothermal analysis should be used for cold-climate projects. Jiangsu Aotelong New Materials Co., Ltd. provides installation guidance, test reports and technical support to inform design decisions and to assist with project submittals.

Q2: How does aluminum foil woven composite compare to PE film-only vapor barriers?

A2: The aluminum metallised face reduces radiant heat transfer in addition to providing lower emissivity than standard polyethylene films. The woven reinforcement increases tensile, tear and puncture resistance compared with film-only membranes, improving durability during handling and fastening. For projects requiring documented performance, request third-party test data and factory inspection records from Jiangsu Aotelong New Materials Co., Ltd.

Q3: What manufacturer certifications and test support are available?

A3: Jiangsu Aotelong New Materials Co., Ltd. is based in Yangzhou City, Jiangsu Province and operates as an integrated R&D, production and sales enterprise within the Yangtze River Delta new materials sector. The company’s product range includes vapor barrier membranes, reflective insulation membranes and a variety of nonwoven and composite materials. Jiangsu Aotelong has completed US ICC-ES and UK BBA factory inspections; selected products hold test reports from the National Building Materials Testing Center and CE/BBA documentation where applicable. Certification and factory inspection documents are available to support procurement and compliance requirements.

日本語

日本語 Русский

Русский España

España عرب .

عرب .