Key Technical Features

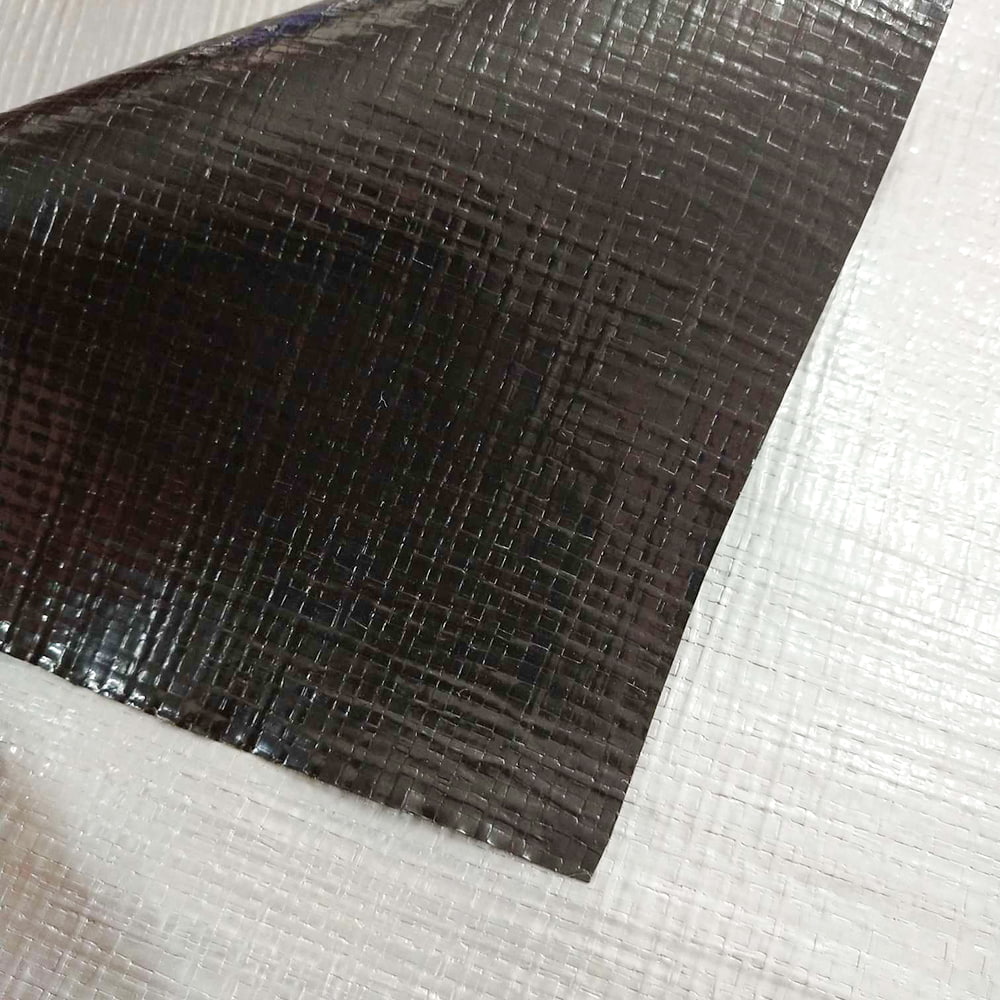

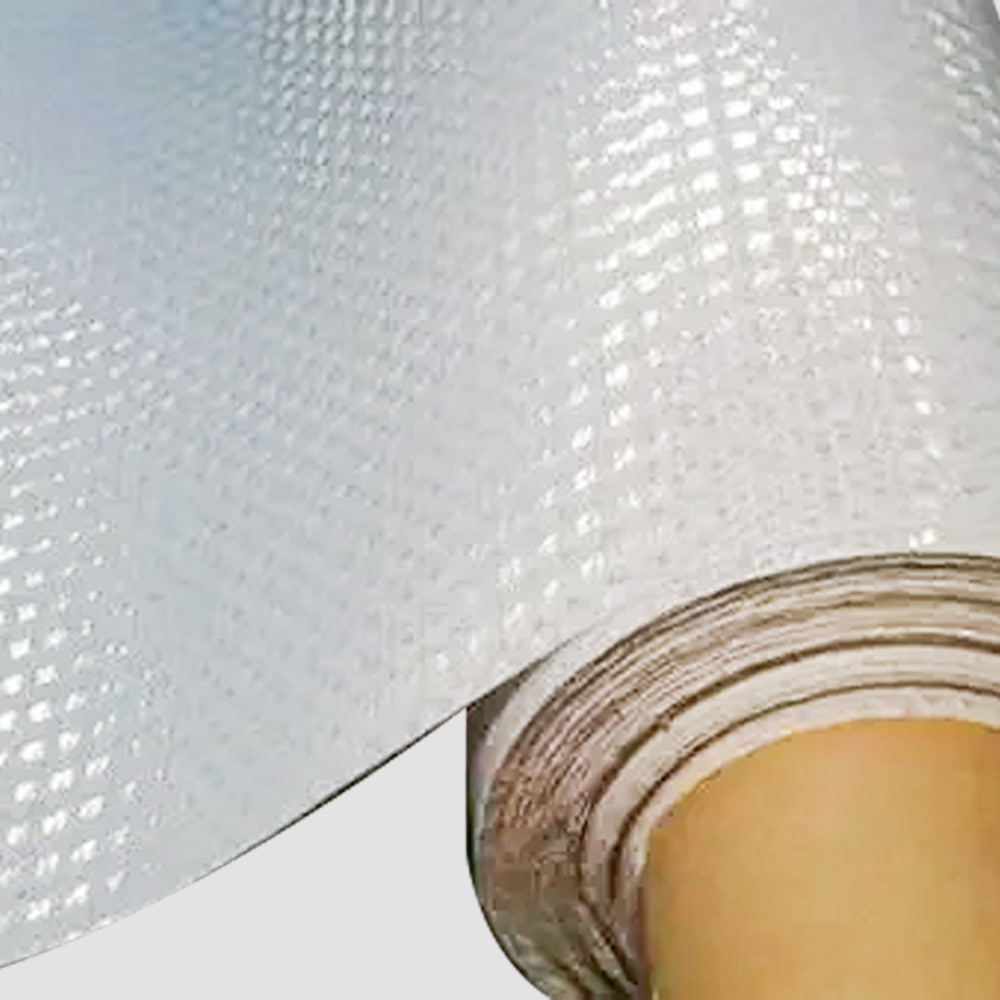

- Composite construction: spunbond non-woven + reinforced woven PE + PE lamination to combine vapour control and mechanical durability.

- Vapour control: low permeance designed to limit water vapour transmission in conditioned wall and roof assemblies.

- Mechanical reinforcement: woven PE scrim improves tear resistance and fastener retention during installation.

- Dimensional stability: laminated finish resists stretching and wrinkling under normal site conditions.

- Compatibility with common tapes, sealants and mechanical fasteners used in non-woven vapor barrier for roof underlay installations.

Typical Applications

Roof underlay and reflective assemblies

Applied beneath roofing membranes or insulation as a vapor control layer to reduce inward and outward moisture migration. Suitable for pitched and flat roof systems where a reinforced PE underlay is specified.

Wall cavity and framed assemblies

Installed on the warm side of insulation where project hygrothermal analysis indicates a need for a continuous vapor barrier. The woven reinforcement supports fastening and maintains continuity across vertical substrates.

Sub-floor underlayment and retrofit works

Used as a temporary or permanent underlayment to control ground moisture intrusion in sub-floor applications and to provide a stable surface for subsequent insulation layers.

Performance and Benefits (Technical)

- Reduced vapour transmission to mitigate condensation risk within enclosed building cavities.

- Improved installation durability through woven reinforcement which reduces on-site damage versus single-layer films.

- Suitability for large-format installation with roll widths and lengths that reduce site join frequency and labour time.

- Testable properties available on request for project submittals, including WVTR, tensile strength and tear resistance.

Installation Guidance

General

Install with the laminated PE face oriented per project specification. Provide overlaps and tape joints using compatible vapor-barrier tapes. Maintain continuous sealing around penetrations, junctions and terminations to preserve the vapor barrier function.

Roof application notes

- Lay rolls crosswise or lengthwise as specified by the roofing system design; typical overlap: 50–150 mm.

- Use mechanical fasteners or approved adhesives consistent with substrate type and wind uplift requirements.

Wall application notes

- Position on the warm side of insulation in cold climates unless project analysis indicates otherwise.

- Seal to structural members using approved sealants and tapes specified for vapor control membranes.

Technical Specifications (Typical values)

Values below represent common product options. Project-specific values and test reports are available upon request.

| Construction | Spunbond non-woven + Woven PE scrim + PE laminated surface | Composite lamination for vapour control and reinforcement |

| Nominal thickness | 0.18 mm – 0.45 mm | Selectable per order |

| Basis weight (GSM) | 80 – 220 g/m² | Depends on nonwoven weight and lamination |

| Water vapour transmission (WVTR) | < 0.2 g/m²·24h (typical) | Measured per ASTM or ISO on request |

| Permeance | Low permeance class | Suitable as a vapor barrier membrane for building envelope |

| Tensile strength (MD / CD) | ≥ 180 N / 140 N (typical) | Directional values depend on woven scrim orientation |

| Tear resistance | ≥ 100 N (Elmendorf or equivalent) | Enhanced by woven reinforcement |

| Puncture resistance | Improved vs. single-layer PE films | Depends on scrim density |

| Operating temperature | -40 °C to +110 °C (short term +130 °C) | Dependent on PE grade |

| Roll widths | 0.6 m, 1.0 m, 1.2 m, 1.5 m (custom available) | Specify on order |

| Roll lengths | 25 m, 50 m, 100 m | Varies by product code |

| Fire classification | Project-specific ratings available | Provide code references for testing requirements |

| Certifications & testing | Factory inspection and third-party test reports available | Certificates provided for project submittals on request |

| Packaging | Core-wound rolls, wrapped and palletised | Export packaging options available |

Ordering and Customization

Custom options include non-woven weight, woven scrim density, lamination thickness and roll dimensions. For quotations, supply required roll sizes, target vapour permeance (WVTR), expected installation environment and any applicable building codes. Lead time and pricing depend on order quantity and certification needs.

Frequently Asked Questions (FAQ)

Q1: Is this product suitable as a continuous vapor barrier for both roof and wall systems?

A1: When installed with fully sealed overlaps, sealed penetrations and appropriate terminations, the product performs as a vapor barrier membrane for roof and wall assemblies. Use of compatible tapes and sealants is required to maintain continuity. Jiangsu Aotelong New Materials Co., Ltd. supplies technical documentation and test data to support installation details and project submittals.

Q2: How does the reinforced woven PE underlay compare to standard polyethylene films for construction?

A2: The combination of a spunbond non-woven layer and a woven PE scrim increases mechanical robustness relative to single-layer polyethylene films. This results in improved tear resistance and fastener holding capacity during installation, while providing controlled vapour permeance. For projects requiring specific WVTR, tensile or puncture properties, Jiangsu Aotelong New Materials Co., Ltd. can provide test reports from the National Building Materials Testing Center and other certification bodies upon request.

Q3: What certifications and manufacturer support are available for project procurement?

A3: Jiangsu Aotelong New Materials Co., Ltd. is based in Yangzhou City, Jiangsu Province and integrates R&D, production and sales. The company’s product range includes vapor barrier membranes, reflective insulation membranes and a variety of nonwoven and composite materials. Jiangsu Aotelong has completed factory inspections such as US ICC-ES and UK BBA; select products hold CE and BBA related test documentation. Manufacturer certificates, factory inspection reports and third-party test results are provided to meet procurement requirements.

日本語

日本語 Русский

Русский España

España عرب .

عرب .